Pucherite-based photocatalyst and preparation method and application thereof

A technology of photocatalyst and bismuth vanadate, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Changes, unsatisfactory control effects, etc., to achieve the effect of simple and easy preparation of the catalyst, low price, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

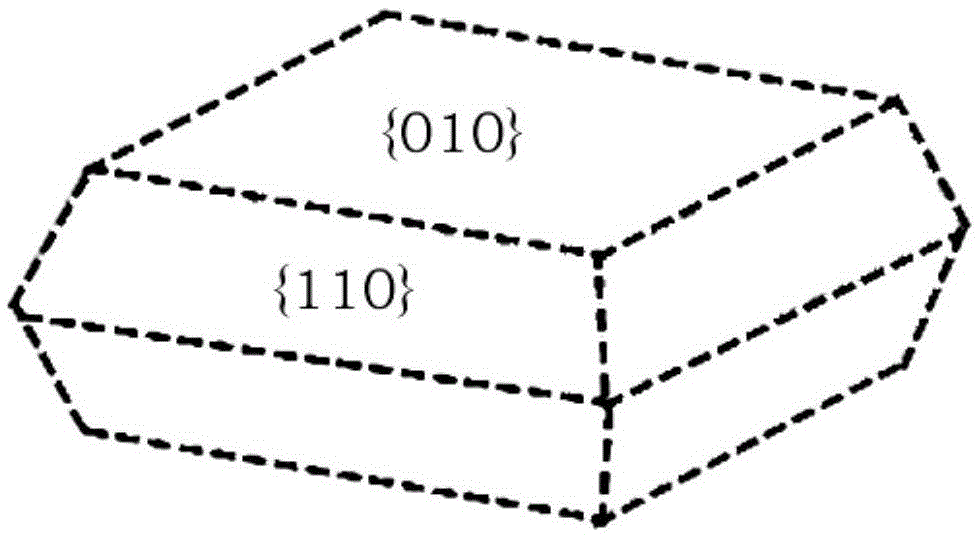

[0034] Precursor NH 4 VO 3 (50mmol) and Bi(NO 3 ) 3 ·5H 2 O (50 mmol) was dissolved in 200 mL of an aqueous solution with a nitric acid concentration of 2.0 M, and the pH of the solution was adjusted to 2.0 with ammonia water under stirring conditions. Then add a certain amount of KCl to adjust the concentration of chloride ions in the solution to be 0.03moldm -3 . After aging for 2 h, the precipitate was transferred to a PTFE-lined stainless steel autoclave with a capacity of 100 mL for hydrothermal treatment at 210 °C for 20 h. After cooling, the orange-yellow powder was separated by filtration, washed several times with deionized water, and dried overnight at 60°C. After drying, the powder was calcined at 500°C for 2h. That is, BiVO with {010} crystal face exposure ratio of 20% 4 - {010} 20% Catalyst. Take 10mg of the prepared BiVO 4 - {010} 20%, added to 5mL formaldehyde-water solution with a mass percentage of formaldehyde of 20%. Vacuumize or pass inert gas un...

Embodiment 2

[0036] Precursor NH 4 VO 3 (50mmol) and Bi(NO 3 ) 3 ·5H 2 O (50mmol) was dissolved in 200mL of 2.0M aqueous solution of nitric acid, and the pH value of the solution was adjusted to 1.8 with ammonia water under stirring conditions. Then add a certain amount of NaCl to adjust the concentration of chloride ions in the solution to be 3.0moldm -3 . After aging for 2 h, the precipitate was transferred to a PTFE-lined stainless steel autoclave with a capacity of 100 mL for hydrothermal treatment at 190 °C for 30 h. After cooling, the orange-yellow powder was separated by filtration, washed several times with deionized water, and dried overnight at 60°C. After drying, the powder was calcined at 500°C for 2h. That is, BiVO with {010} crystal plane exposure ratio of 80% 4 - {010} 80% Catalyst. Further use of photodeposition method in BiVO 4 The {110} facet deposited MnO x , that is, MnO x -BiVO 4 - {010} 80% Catalyst. Take 10mg of the prepared MnO x -BiVO 4 -{010}80%, a...

Embodiment 3

[0038] Precursor NH 4 VO 3 (60mmol) and Bi(NO 3 ) 3 ·5H 2 O (60mmol) was dissolved in 200mL of an aqueous solution with a nitric acid concentration of 2.0M, and the pH of the solution was adjusted to 2.0 with ammonia water under stirring conditions. Then add a certain amount of ZnCl 2 Used to adjust the concentration of chloride ions in the solution to 0.5moldm -3 . After aging for 2 h, the precipitate was transferred to a PTFE-lined stainless steel autoclave with a capacity of 100 mL for hydrothermal treatment at 200 °C for 24 h. After cooling, the orange-yellow powder was separated by filtration, washed several times with deionized water, and dried overnight at 60°C. After drying, the powder was calcined at 500°C for 2h. That is, BiVO with a {010} crystal plane exposure ratio of 60% 4 - {010} 60% Catalyst. Further use of photodeposition method in BiVO 4 Pt is deposited on the {010} crystal plane, and MnO is deposited on the {110} crystal plane x , that is, Pd-MnO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com