Liquefaction-resisting prefabricated concrete square drainage pile

A precast concrete, anti-liquefaction technology, used in sheet pile walls, protection devices, buildings, etc., can solve the problem that the excess pore water pressure in the drainage channel cannot be dissipated in time, cannot ensure that excess pore water dissipates in time, and the perforated steel wire hose should be rusted. To ensure smooth and effective drainage area, meet anti-liquefaction requirements, and achieve good drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

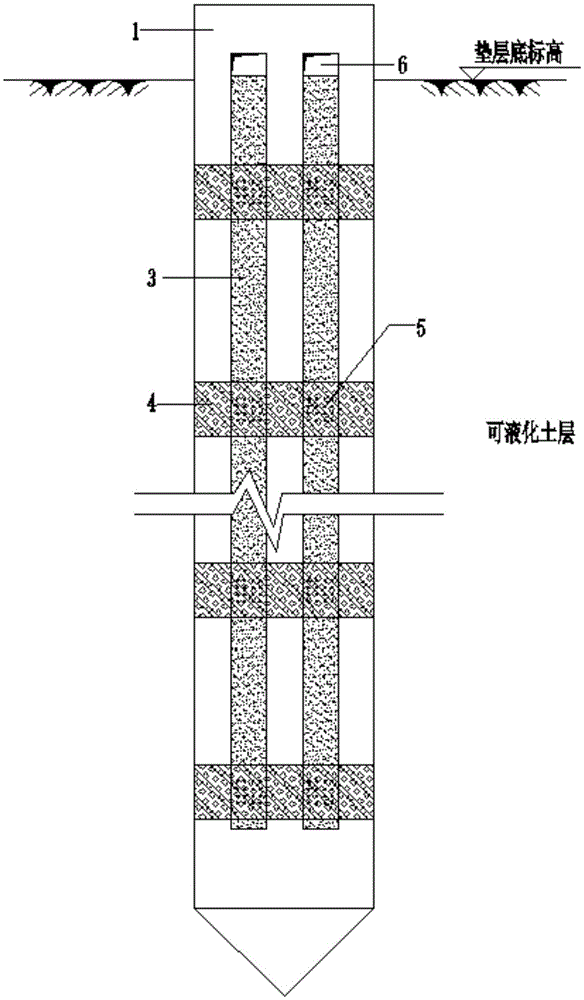

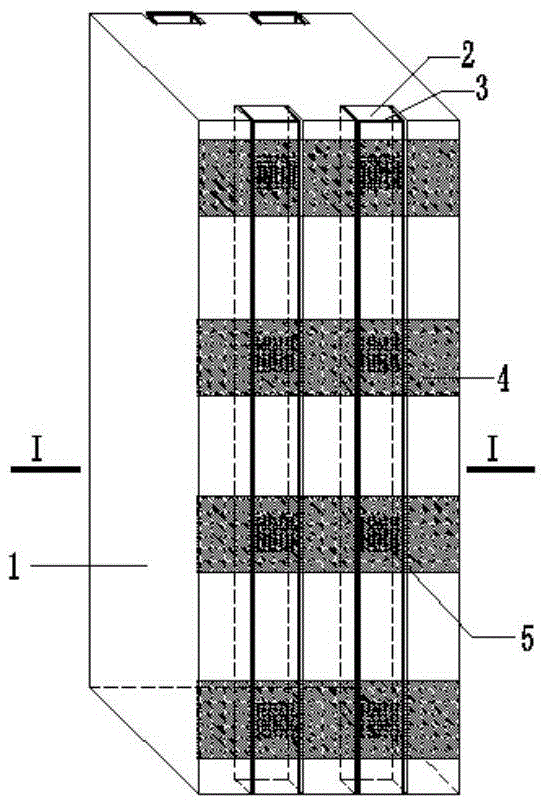

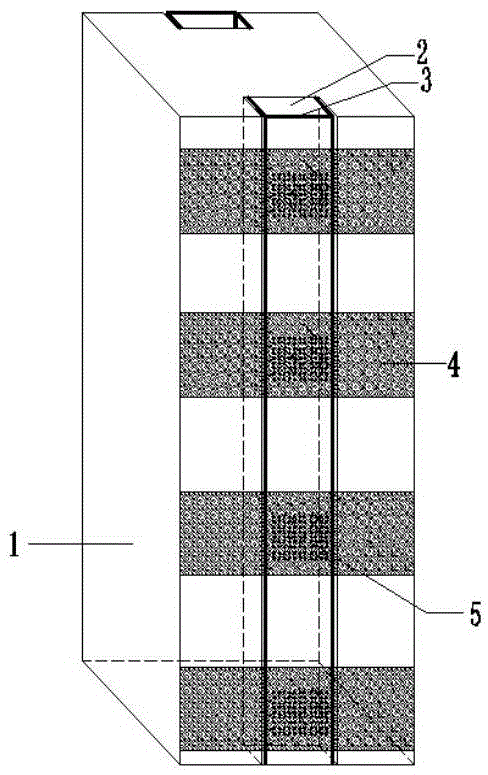

[0039]As mentioned in the background technology section, in view of the technical problems existing in the current gravel piles and rigid piles, the present invention provides a prefabricated concrete square pile with anti-liquefaction and drainage. The pile body has high strength and can meet the requirements of improving the bearing capacity of the foundation. During an earthquake, the pile effect can be fully utilized to reduce liquefaction, and the drainage channel is sufficient to ensure the timely dissipation of excess pore water pressure. At the same time, the structure is simple and the construction is convenient, which is conducive to mass production.

[0040] Such as Figure 1-Figure 6 As shown, the anti-liquefaction drainage prefabricated concrete square pile includes a prefabricated concrete square pile 1, and the side of the prefabricated concrete square pile is provided with a groove that does not penetrate the top surface and the bottom surface of the square pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com