Corrosion and abrasion resistant Cr-DLC coating for aluminum alloy surface and preparation methods of Cr-DLC coating

An aluminum alloy surface, anti-corrosion and wear-resistant technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problem of surface roughness of coating size accuracy and the difficulty of preparing high hardness DLC film , laser cladding method to form brittle phases and cracks, etc., to achieve the effect of uniform and dense deposited film, small friction coefficient, good repeatability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

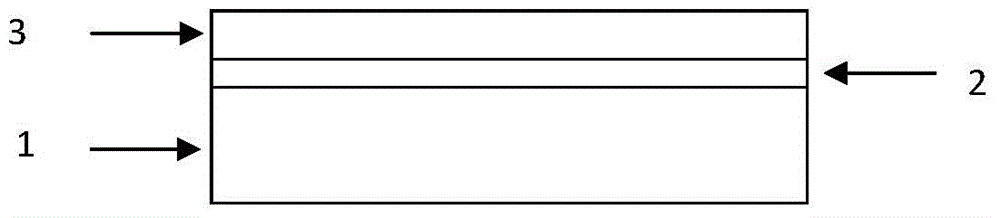

[0039] Another aspect of the present invention provides a method for preparing an anti-corrosion and wear-resistant Cr-DLC coating on the surface of an aluminum alloy, which may include: using magnetron sputtering technology, using graphite and chromium as cathode targets, The anti-corrosion and wear-resistant Cr-DLC coating is prepared on the surface of the alloy.

[0040]In a typical embodiment, a preparation method for an anti-corrosion and wear-resistant Cr-DLC coating on the surface of an aluminum alloy may comprise the following steps:

[0041] Step 1, performing surface pretreatment on the aluminum alloy substrate (hereinafter also referred to as aluminum alloy substrate, aluminum alloy substrate or substrate);

[0042] Step 2, put the pretreated aluminum alloy substrate on the substrate holder in the vacuum chamber of the magnetron sputtering equipment, and evacuate the vacuum chamber of the magnetron sputtering equipment;

[0043] Step 3, introduce high-purity Ar (pu...

Embodiment 1

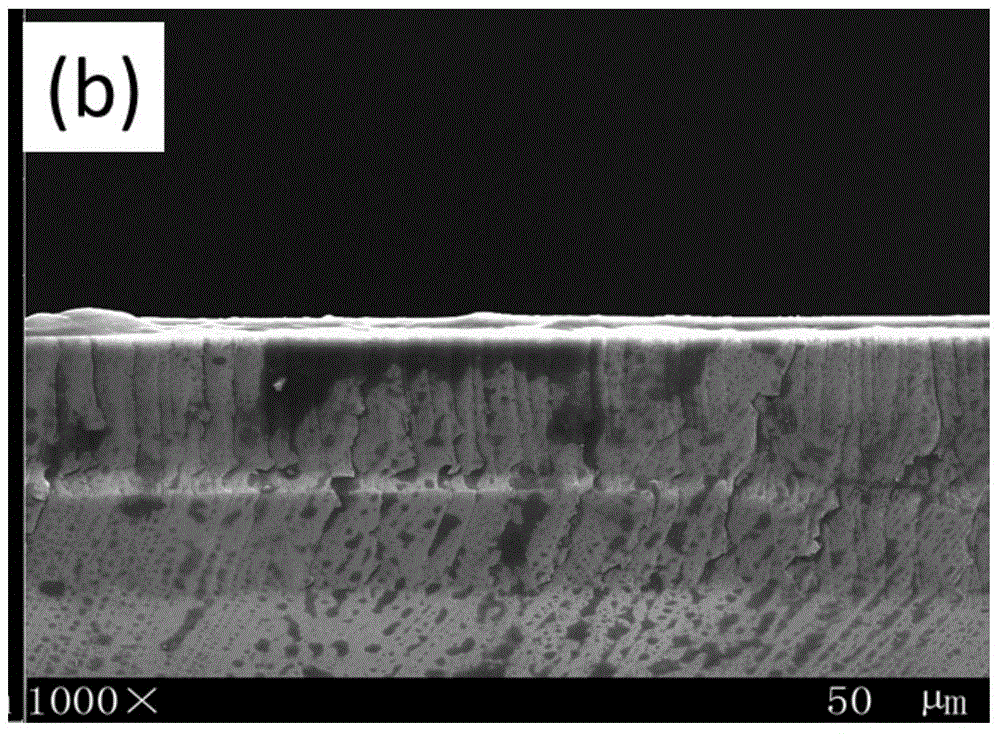

[0054] (1) Process the aluminum alloy into a square with a side length of 25 mm and a thickness of 3 mm.

[0055] (2) Use ordinary detergent to degrease and decontaminate the processed aluminum alloy substrate, and then use 400-1200 # The samples were polished with sandpaper, and finally the surface was polished to a surface roughness of 30 nm. Put the polished aluminum alloy into acetone and absolute ethanol to ultrasonically clean it for 10 min respectively, and finally use N 2 blow dry.

[0056] (3) Put the aluminum alloy substrate after polishing and cleaning into the vacuum chamber of the magnetron sputtering equipment, then close the vacuum chamber, and evacuate until the vacuum degree is less than or equal to 3.0×10 -3 Pa.

[0057] (4) Introduce high-purity Ar, and at the same time turn on the graphite column arc with a current of 0.2A, turn on the chromium column arc with a current of 0.3A, and apply a -500V bias to bombard and clean the substrate for 30 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion potential | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com