Method for rapid determination of hyaluronidase activity

A hyaluronidase and rapid assay technology, applied in the direction of biochemical equipment and methods, microbial assay/inspection, etc., can solve the problems of insufficient response to hyaluronidase activity, high requirements for experimental conditions, and high requirements for conditions, and achieve Determination of good stability, high application value, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Microplate reader replaces ultraviolet spectrophotometer to make the standard curve of hyaluronic acid content

[0042] Food and Fermentation Industry. 2009,35(1) "Research on Rapid Detection Method of Hyaluronic Acid Content in Fermentation Broth [J]" disclosed CTAB method to measure hyaluronic acid content. Most of the detection instruments are ultraviolet spectrophotometers, but ultraviolet spectrophotometers The photometer cannot measure multiple samples at the same time, and requires a large sample volume. The microplate reader can measure multiple samples at the same time. It uses a disposable 96-well plate, which is very convenient to operate and can reduce the error of the cuvette.

[0043] Add 5-50 μl of hyaluronic acid (concentration 1 μg / μl) into 1.5ml EP tube with 200 μl of sodium acetate buffer solution, supplement 250ul with sodium acetate buffer solution, then add 500ul of CTAB, put it into a 37℃ water bath, and start timing from the additio...

Embodiment 2

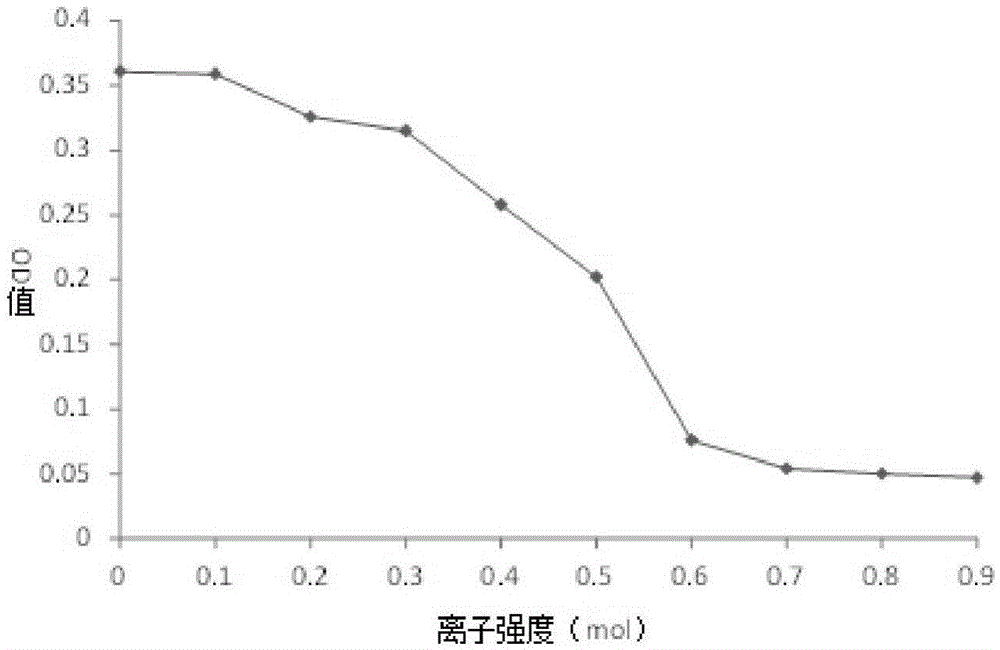

[0044] Embodiment 2: The impact of ionic strength on CTAB nephelometry

[0045] Based on the 0.2M sodium acetate buffer solution, adjust the ionic strength with sodium chloride to 0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9M under the condition of constant pH=6 The above-mentioned ionic strength is the ionic strength of sodium chloride), 10 sodium acetate buffer solutions with different ionic strengths and 50 μg of hyaluronic acid are mixed with it to form a 1 μg / μl hyaluronic acid solution, then add 500ulCTAB, put into 37 ℃ water bath, start timing from the addition, and the reaction time is 10 minutes; then accurately take 200 μl of the solution to a 96-well plate, and use a microplate reader to measure the OD value of the solution at a wavelength of 400 nm.

[0046] From figure 2 It can be seen that as the ionic strength increases, the OD value decreases; Table 1 shows that the ionic strength above 0.6M hardly produces turbidity compared with the control. From Figur...

Embodiment 3

[0053] Embodiment 3: pH value influences on CTAB turbidity method

[0054] Hyaluronidase activity pH is generally between 3-7, so based on 0.2M sodium acetate buffer, adjust the pH value with glacial acetic acid, prepare hyaluronic acid solutions with different pH values, the concentration is 1 μg / μl, the solution pH The values are 3, 4, 5, 6, 7 respectively, and it is found that no turbidity is generated when pH=3 during the CTAB turbidimetry experiment. Take 50ul of hyaluronic acid solutions with different pH values and add them into different 1.5ml EP tubes that have been marked. There are 200ul of sodium acetate buffer solutions with different pH values in the tubes. Add 500 μl of CTAB solution, react in a 37°C water bath for 10 minutes, accurately take 200ul of the reaction solution and add it to a 96-well plate, and use a microplate reader to measure the OD value at a wavelength of 400nm

[0055] Figure 4 It can be seen that as the pH increases, the OD value als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com