Graphite carbon/ferric oxide composite material and its preparation method and application

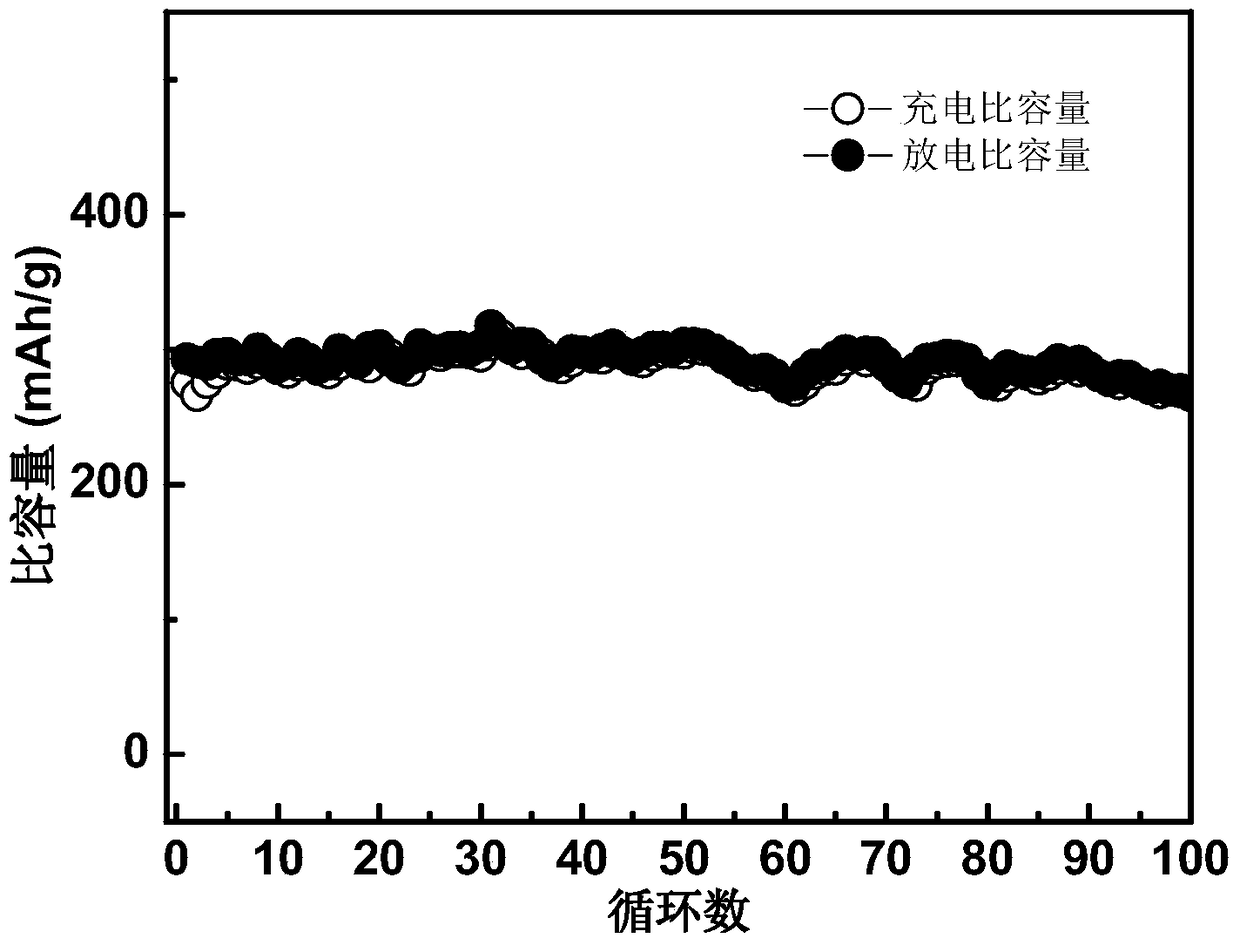

A technology of ferroferric oxide and composite materials, which is applied in the field of new energy materials, can solve the problems of complex synthesis process, inability to meet industrial mass production, and high cost, and achieve the effect of simple preparation process, good cycle stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment prepares a kind of graphite carbon / ferric oxide composite material, and the steps are as follows:

[0042] (1) Take by weighing 0.3g ferrous gluconate and 1.5g F127 respectively, then the two are added to 15ml deionized water, that is, the mass ratio of ferrous gluconate, F127 and deionized water is 1:5:50, after Mix well to obtain solution I.

[0043] (2) Add 0.325 g of polyetherimide to solution I, stir for 30 minutes, and mix uniformly to obtain solution II; freeze-dry solution II for 12 hours to obtain solid powder.

[0044] (3) Under an Ar atmosphere, anneal the solid powder, that is, slowly heat the solid powder to 700°C, keep it warm for 4 hours, and then cool it to room temperature, wherein the heating rate is 2°C / min, and the cooling rate is 5°C / min; finally The obtained black solid powder is the nano-particles of graphitic carbon wrapped ferric oxide.

[0045] Figure 4 For the transmission electron micrograph picture (i.e. TEM figure...

Embodiment 2

[0049] The present embodiment prepares a kind of graphite carbon / ferric oxide composite material, and the steps are as follows:

[0050] (1) Take by weighing 0.3g ferrous gluconate and 1.5g F127 respectively, then the two are added to 15ml deionized water, that is, the mass ratio of ferrous gluconate, F127 and deionized water is 1:5:50, after Mix well to obtain solution I.

[0051] (2) Add 0.4 g of polyetherimide to solution I, stir for 30 minutes, and mix uniformly to obtain solution II; freeze-dry solution II for 12 hours to obtain solid powder.

[0052] (3) Under an Ar atmosphere, anneal the solid powder, that is, slowly heat the solid powder to 700°C, keep it warm for 4 hours, and then cool it to room temperature, wherein the heating rate is 2°C / min, and the cooling rate is 5°C / min; finally The obtained black solid powder is the nano-particles of graphitic carbon wrapped ferric oxide.

[0053] The specific morphology of the composite material prepared in this example is:...

Embodiment 3

[0056] The present embodiment prepares a kind of graphite carbon / ferric oxide composite material, and the steps are as follows:

[0057] (1) Take by weighing 0.3g ferrous gluconate and 1.5g F127 respectively, then the two are added to 15ml deionized water, that is, the mass ratio of ferrous gluconate, F127 and deionized water is 1:5:50, after Mix well to obtain solution I.

[0058] (2) Add 0.28 g of polyetherimide to solution I, stir for 30 minutes, and mix uniformly to obtain solution II; freeze-dry solution II for 12 hours to obtain solid powder.

[0059] (3) Under an Ar atmosphere, anneal the solid powder, that is, slowly heat the solid powder to 700°C, keep it warm for 4 hours, and then cool it to room temperature, wherein the heating rate is 2°C / min, and the cooling rate is 5°C / min; finally The obtained black solid powder is the nano-particles of graphitic carbon wrapped ferric oxide.

[0060] The specific appearance of the composite material prepared in this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com