Combined type anti-corrosion wide-runner sewage heat exchanger

A heat exchanger and combined technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of short service life, poor corrosion resistance, inconvenient for daily maintenance and maintenance, etc. Compact structure, high heat transfer coefficient, anti-corrosion and sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is specifically described below in conjunction with accompanying drawing,

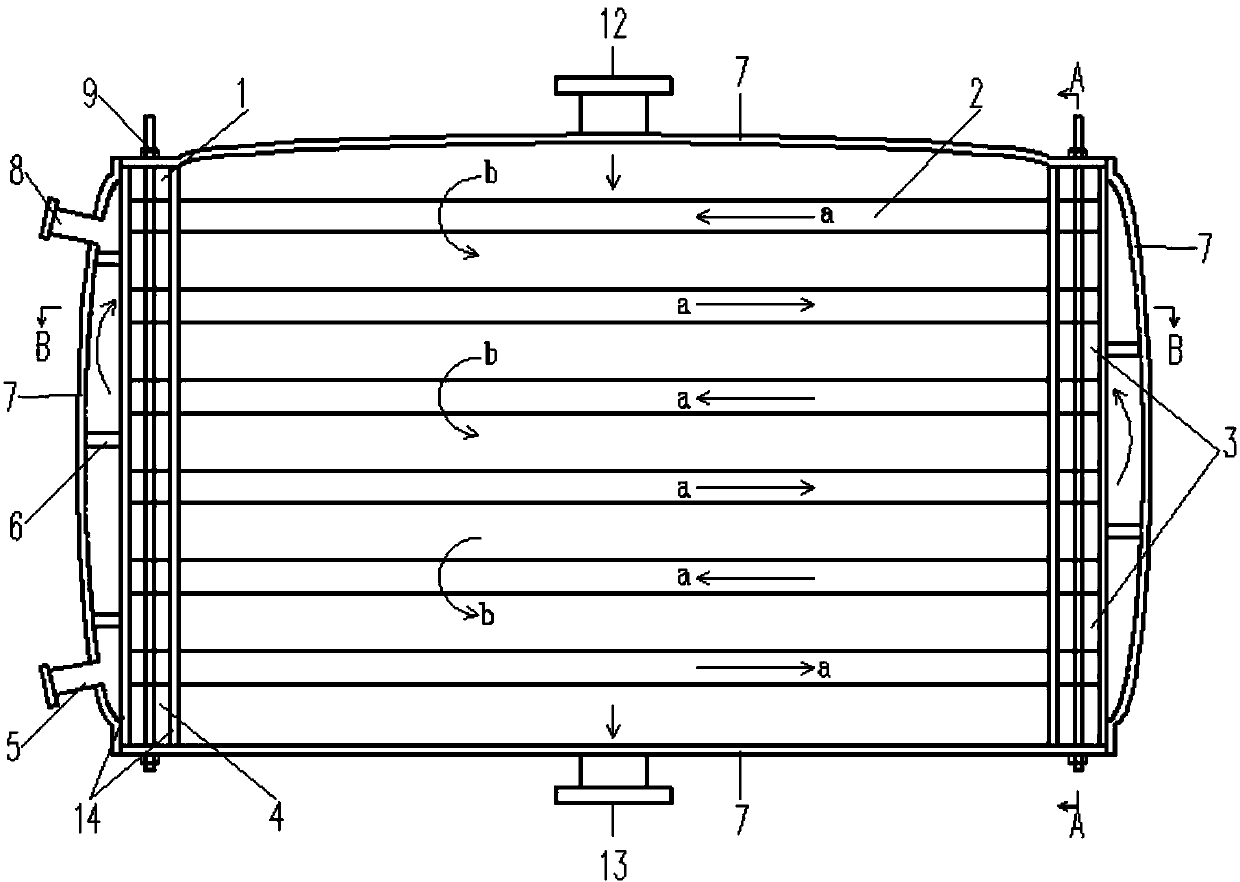

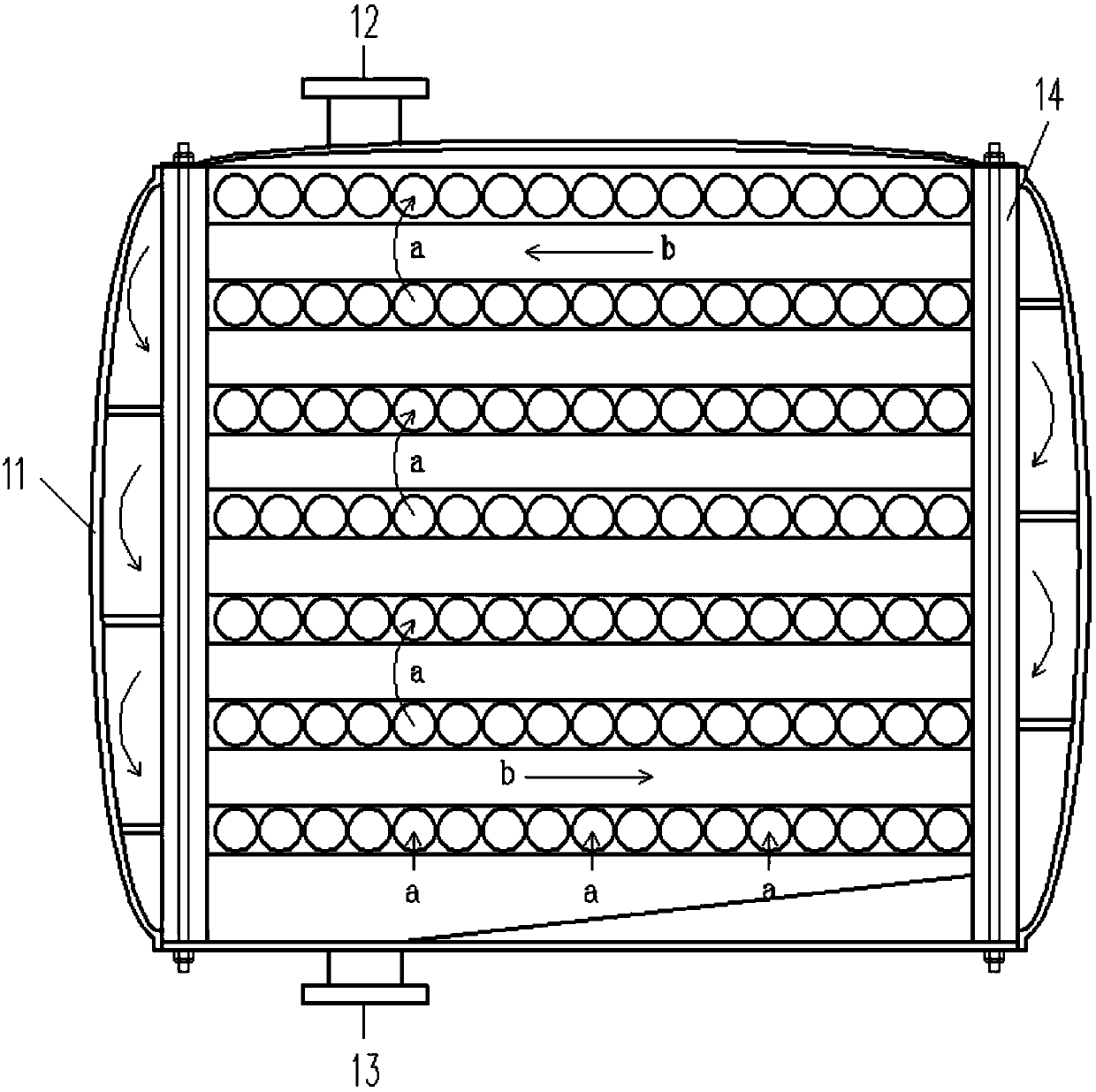

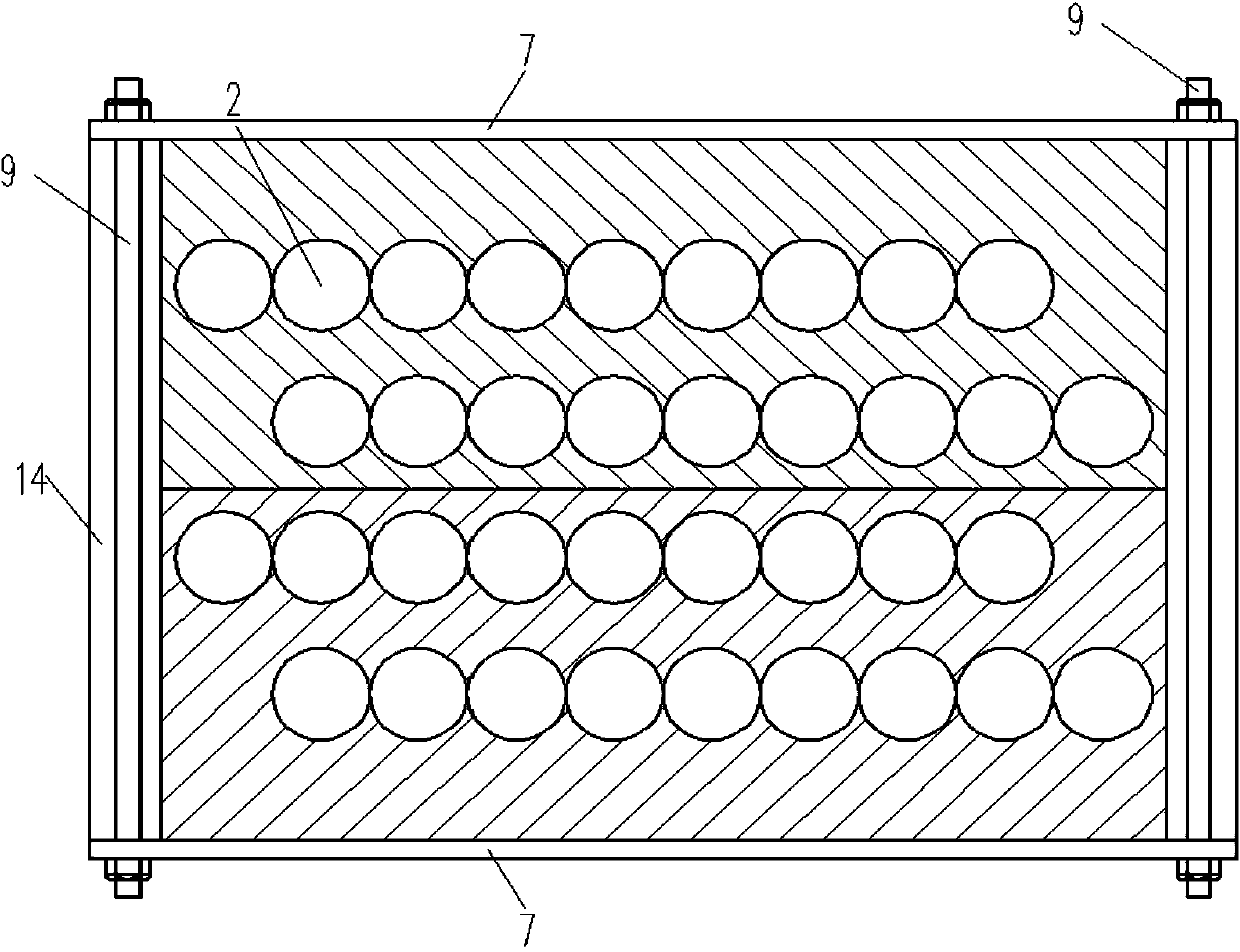

[0018] Such as figure 1 , figure 2 and Figure 4 As shown, the present invention includes a housing 7, a pipe end seat, and a pipe end seat fixing frame 14. The pipe end seat is arranged in the housing 7, and the pipe end seat is a multi-layer combination, including the uppermost upper pipe end The seat 1, the lowermost lower tube end seat 4 and a plurality of intermediate tube end seats 3 are combined into one body through the tube end seat fixing bracket 14 with bolts 9; the tube end seat is provided with a groove 21 matching the shape of the heat exchange tube , the heat exchange tube 2 is arranged between the tube end seats; the nozzle of the heat exchange tube 2 is fixed in the fixed space formed by the groove 21 of the adjacent upper and lower tube end seats; in the axial direction of the heat exchange tube 2 Deflector ribs 6 are arranged at intervals between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com