A kind of vacuum insulation board and its manufacturing method

A technology of vacuum heat insulation board and production method, which is applied in the direction of heat insulation protection pipelines, heat exchange equipment, heat preservation, etc., and can solve the problems of difficult vacuuming and easy blockage of vacuum pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

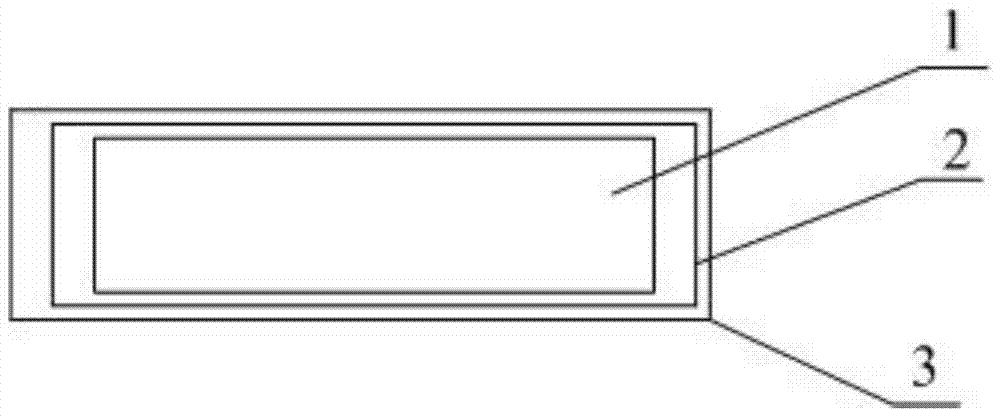

[0077] A vacuum heat insulation panel, the vacuum heat insulation panel comprises a core material, a non-woven bag and a gas barrier membrane bag, the core material is pure SiO 2 airgel, the pure SiO 2 The airgel contains a getter, the size of the vacuum insulation panel is 200mm×200mm×10mm, the non-woven bag wraps the core material, and the gas-barrier membrane bag wraps the non-woven bag and the core material The number of layers of the non-woven bag is 2, the single layer thickness is 20 μm, the pore size distribution is 0.26-2.23 μm, and the porosity is 75%; one bag surface of the gas barrier membrane bag is a polyester membrane, and the other bag surface is It is a composite film of aluminum foil and polyester diaphragm.

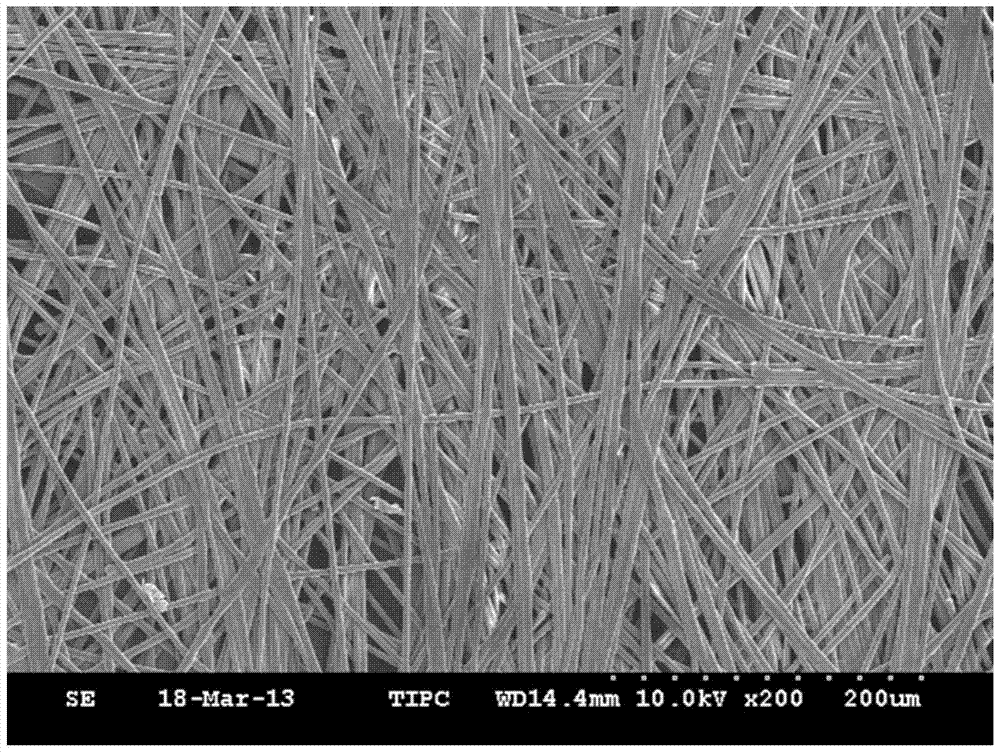

[0078] The non-woven bag is made by pure electrospinning process, and its secondary electron scanning electron microscope picture is as follows: image 3 As shown, it can be seen from the figure that the filter bag is formed by stacking nanofibers, an...

Embodiment 2

[0087] A vacuum heat insulation panel, the vacuum heat insulation panel comprises a core material, a non-woven bag and a gas barrier membrane bag, the core material is pure SiO 2 airgel, the pure SiO 2 The airgel contains a getter, the size of the vacuum insulation panel is 200mm×200mm×10mm, the non-woven bag wraps the core material, and the gas-barrier membrane bag wraps the non-woven bag and the core material The number of layers of the non-woven bag is 5, the thickness of a single layer is 40 μm, the pore size distribution is 0.20-2.10 μm, and the porosity is 70%; one bag surface of the gas barrier membrane bag is a polyester membrane, and the other bag surface is It is a composite film of aluminum foil and polyester diaphragm.

[0088] The non-woven bag is made by electrospinning and melt-blown composite technology, and the SEM images of the front and back are as follows Figure 4 with Figure 5 As shown, it can be seen from the figure that the pore size of the non-wove...

Embodiment 3

[0096] A vacuum heat insulation panel, the vacuum heat insulation panel comprises a core material, a non-woven bag and a gas barrier membrane bag, the core material is pure SiO 2 airgel, the pure SiO 2 The airgel contains a getter, the size of the vacuum insulation panel is 200mm×200mm×10mm, the non-woven bag wraps the core material, and the gas-barrier membrane bag wraps the non-woven bag and the core material The number of layers of the non-woven bag is 3, the single-layer thickness is 10 μm, the pore size distribution is 70-85 μm, and the porosity is 80%; one bag surface of the gas barrier membrane bag is a polyester membrane, and the other bag surface is Composite film of aluminum foil and polyester separator.

[0097] The manufacturing method of the vacuum insulation panel includes the following steps:

[0098] (1) Select SiO with a particle size distribution of 2.5-3.5mm, a pore diameter between 10-20nm, and a porosity greater than 90%. 2 Airgel, add a small amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com