Anti-static/flame-retardant XPE environment-friendly foam material for vehicle and preparation method of XPE environment-friendly foam material

A foaming material and antistatic technology, which is applied in the field of antistatic/flame retardant vehicle XPE environmental protection foaming material and its preparation, can solve the problems of burning, loss, easy melting, etc., and achieve good plasticity, strong toughness, good The effect of chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

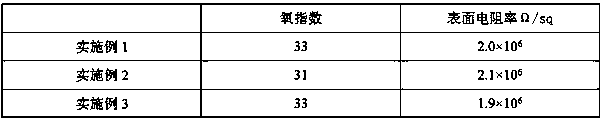

Examples

preparation example Construction

[0027] The preparation method of antistatic / flame-retardant vehicle XPE environment-friendly foaming material, described method comprises as follows:

[0028] (1) Mix the raw materials and add them to the single-screw extruder to extrude the XPE master sheet;

[0029] (2) Then put it into a three-roll calender to clean the XPE master sheet;

[0030] (3) Then put it into the foaming furnace for continuous normal pressure foaming;

[0031] (4) Cool and set the foamed XPE foam sheet on the cooling and setting frame;

[0032] (5) Cut the shaped XPE foam sheet in a cutting machine, and wind up the cut XPE foam sheet in a winder.

[0033] The conditions of the high temperature foaming furnace are: temperature 180-230 degrees

Embodiment 1

[0035] Antistatic / flame retardant vehicle XPE environmentally friendly foaming material is mainly prepared from the following raw materials in parts by weight: 60 parts of PE resin, 4 parts of antistatic agent, 20 parts of self-made composite flame retardant, 5 parts of foaming agent, 2 parts of crosslinking agent, 3 parts of foaming aid.

[0036] The self-made composite flame retardants are: decabromodiphenylethane, trioxide and aluminum hydroxide, the weight ratio of which is 1:1:2.

[0037] The antistatic agent is conductive carbon black.

[0038] The foaming agent is AC foaming agent.

[0039] The crosslinking agent is dicumyl peroxide.

[0040] The foaming aid is zinc stearate.

[0041] The preparation method of antistatic / flame-retardant vehicle XPE environment-friendly foaming material, described method comprises as follows:

[0042] (1) Mix the raw materials and add them to the single-screw extruder to extrude the XPE master sheet;

[0043] (2) Then put it into a ...

Embodiment 2

[0049] Antistatic / flame retardant automotive interior XPE environmentally friendly foaming material is mainly prepared from the following raw materials in parts by weight: 80 parts of PE resin, 8 parts of antistatic agent, 30 parts of self-made composite flame retardant, and 20 parts of foaming agent Parts, 5 parts of crosslinking agent, 5 parts of foaming aid.

[0050] The self-made composite flame retardants are: decabromodiphenylethane, trioxide and aluminum hydroxide, the weight ratio of which is 1:1:2.

[0051] The antistatic agent is conductive carbon black.

[0052] The foaming agent is AC foaming agent.

[0053] The crosslinking agent is dicumyl peroxide.

[0054] The foaming aid is zinc oxide.

[0055] The preparation method of antistatic / flame-retardant vehicle XPE environment-friendly foaming material, described method comprises as follows:

[0056] (1) Mix the raw materials and add them to the single-screw extruder to extrude the XPE master sheet;

[0057] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com