Preparation method and device of ceramic particle reinforced metal matrix composite powder

A metal-matrix composite and ceramic particle technology, which is applied in the field of ceramic particle-reinforced metal-matrix composite powder preparation, can solve the problems of limited types of reinforced particles, restricted applications, and harsh reaction conditions, so as to avoid physical damage, improve product mechanical properties, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

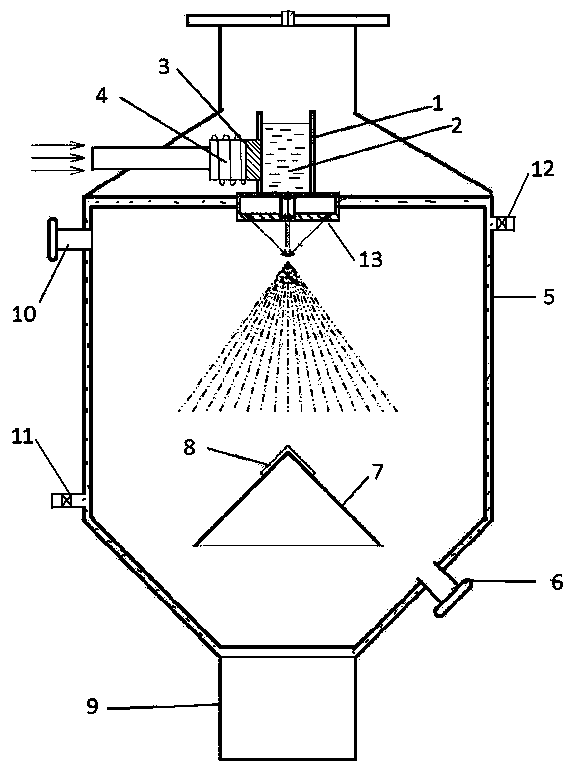

[0020] A method for preparing ceramic particle-reinforced metal-matrix composite powder, comprising the following steps:

[0021] 1. Put the metal matrix raw material into the high-frequency induction furnace 1, and add a set mass fraction of ceramic particle reinforcement. The metal matrix raw material can be any metal material that can be atomized, and its melting point should be lower than 1500°C;

[0022] 2. Vacuumize the high-frequency induction furnace 1, aerosol tank 5, and powder collection tank 9 in the gas atomization equipment to less than 1×10 -4 Pa, then fill the high-purity inert gas argon or helium and maintain the internal pressure of the equipment at 0.1-0.5MPa;

[0023] 3. Turn on the high-frequency induction furnace 1. The typical power of the furnace is 20-200KW. The high-frequency magnetic field generated by the high-frequency coil can quickly heat the raw materials in the high-frequency induction furnace 1. After the raw materials are melted, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com