Ageing strengthening type iron nickel base corrosion resistant alloy easily processed into thick-walled seamless tube

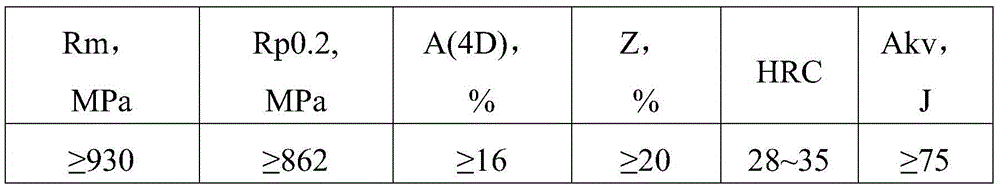

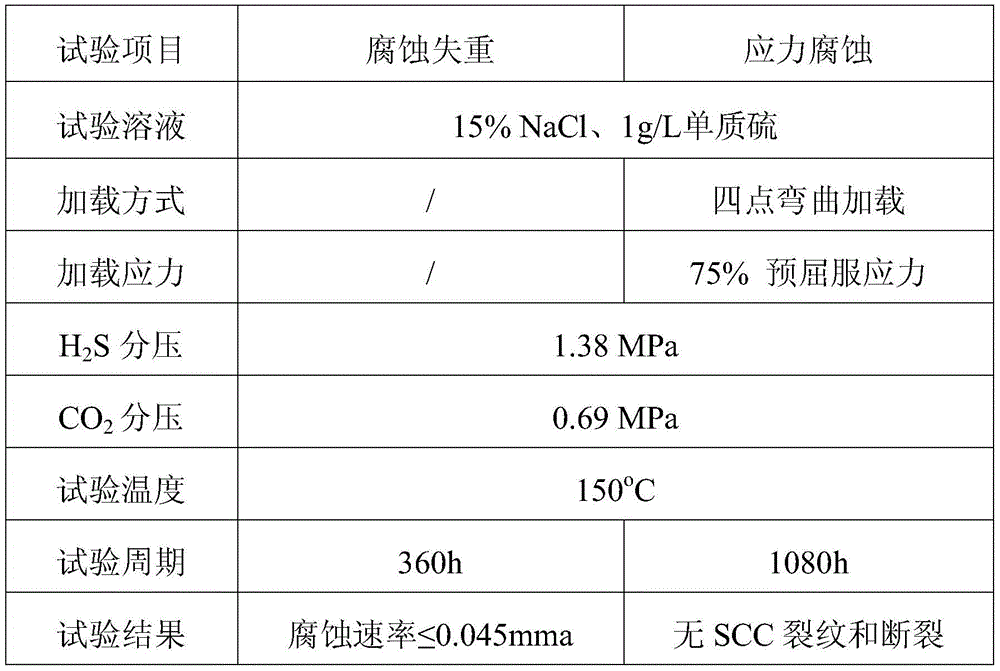

A technology of age-strengthening and corrosion-resistant alloys, applied in the field of alloys, can solve the problems of high hardening rate, narrow high-temperature deformation temperature, poor thermoplasticity, etc., and achieve the effects of improved thermal processing performance, strong resistance to stress corrosion cracking, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0038] Vacuum induction melting alloy 1000kg, the composition is as follows: Ni: 43.7%, Cr: 23.6%, Mo: 3.55%, Cu: 1.78%, Ti: 2.23%, Al: 0.28%, V: 0.025%, Zr: 0.029% , B: 0.0025%, Mg: 0.015%, Nb: 0.36%, C: 0.032%, Si: 0.25%, Mn: 0.32%, Fe: balance. The alloy is cast into a Φ220mm round bar, and then electroslag remelted into a Φ380mm steel ingot, placed in a high-temperature pit furnace for homogenization heat treatment, and then made into a Φ230mm round bar by upsetting, and the bar is machined. Extrude the tube billet, and then make a thick-walled seamless tube of Φ108×22mm by hot extrusion. After the above-mentioned solution heat treatment and double-stage aging heat treatment, a qualified product is produced, and finally machined into a packer for a gas field in eastern Sichuan. .

Embodiment 6

[0040]Vacuum induction melting alloy 3000kg, the composition is as follows: Ni: 42.4%, Cr: 22.75%, Mo: 2.45%, Cu: 2.67%, Ti: 1.83%, Al: 0.48%, V: 0.041%, Zr: 0.019% , B: 0.003%, Mg: 0.013%, Nb: 0.43%, C: 0.04%, Si: 0.32%, Mn: 0.46%, Fe: balance. The alloy is cast into a Φ300mm round bar, then electroslag remelted into a Φ500mm steel ingot, and then placed in a high-temperature pit furnace for homogenization heat treatment, and then subjected to upsetting, drawing, and long blanking by a fast forging machine, and forging by a radial forging machine. It is made into a Φ230mm round bar, processed into an extruded tube billet, and then hot-extruded into a Φ200×30mm thick-walled seamless pipe. After the above-mentioned solution heat treatment and double-stage aging heat treatment, a qualified product is produced, and finally It is machined into a downhole pipe hanger and used in a sour oilfield in Xinjiang.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com