A kind of toughened modified transparent PET sheet composite material and preparation method thereof

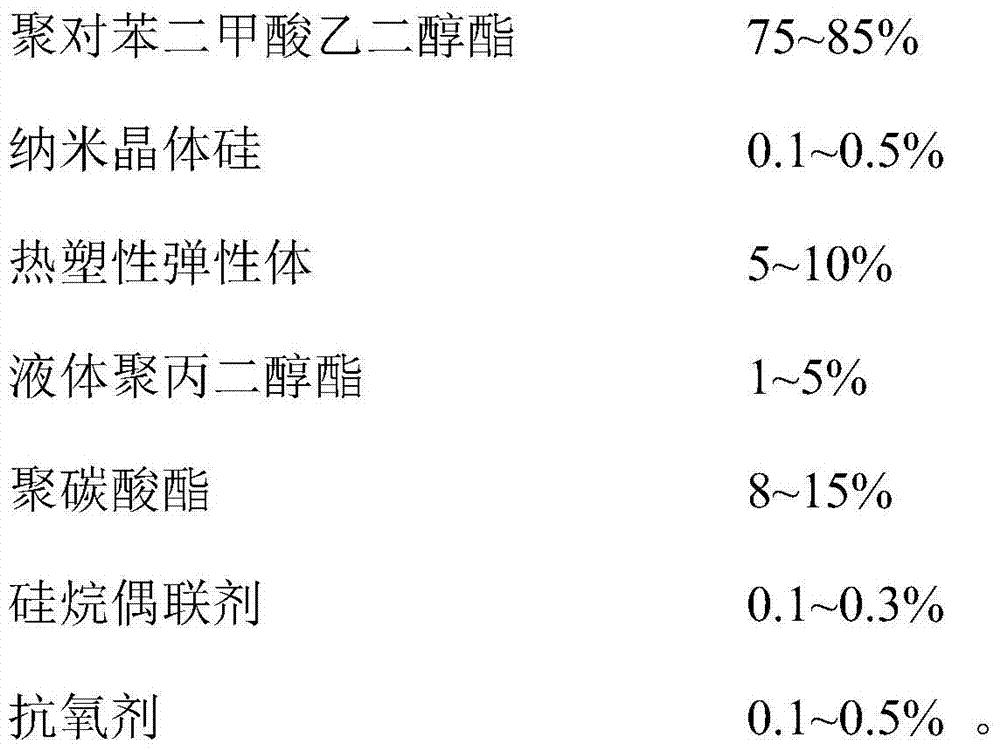

A technology of toughening modified and composite materials is applied in the field of toughened modified transparent PET sheet composite materials and its preparation, which can solve the problems of increasing material cost, strength, rigidity, and heat resistance, and achieve consistent optical properties. , Excellent impact strength, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

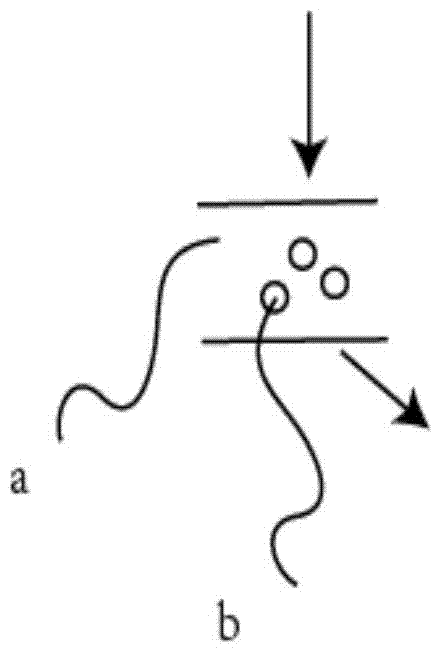

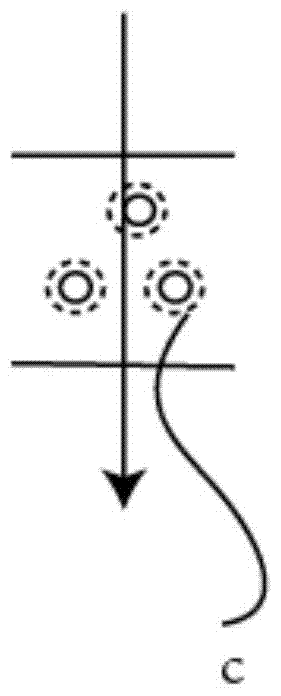

Image

Examples

Embodiment 1-5

[0038] The preparation method of embodiment 1-5 is:

[0039] First dry the polyethylene terephthalate in an oven at 170°C for 3 hours, and at the same time, treat the nanocrystalline silicon with the silane coupling agent, then mix it with the thermoplastic elastomer, and finally Mix the raw materials of other components uniformly to form a blend, melt and extrude through a twin-screw extruder, dry and cool, and granulate;

[0040] Among them, the surface treatment method of nanocrystalline silicon is: add a certain amount of nanocrystalline silicon into the mixed solution of absolute ethanol / water (volume ratio is 3:1), and make it fully dispersed under 4000r / min high-speed shear, adjust The shear rate is 2000r / min, the reaction temperature is about 70°C, the silane coupling agent is added, and the pH value of the system is adjusted to about 4 with oxalic acid solution. After reacting for 90 minutes, the suspension of nanocrystalline silicon is suction-filtered, and the filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com