Method for preparing ethanol through hydrogenation of acetate

A technology for hydrogenation of acetate and production of ethanol, which is applied to chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of low conversion rate and selectivity of hydrogenation of acetate, improve service life, Pollution reduction, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

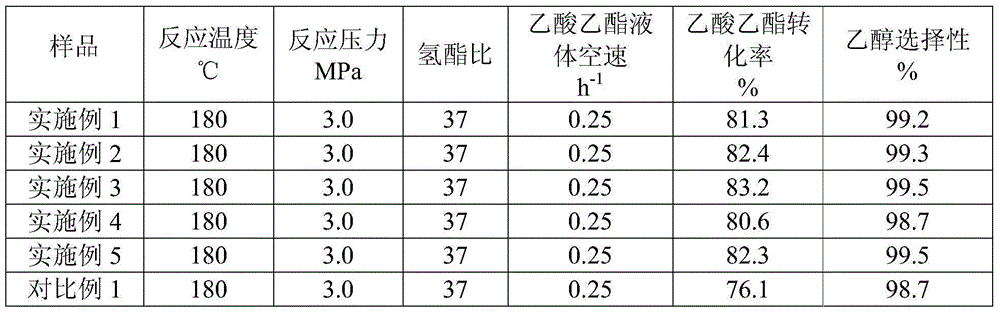

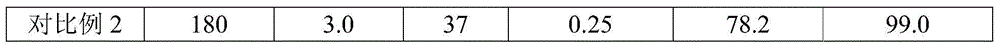

Examples

Embodiment 1

[0050] (1) Weigh 50g of nylon-6 particles (Baling Petrochemical, BL2340-H) and place it in the copper-aluminum alloy powder. The Cu content in the copper-aluminum alloy is 50wt%, and the Al content is 50wt%. Molding at 220°C and pressure of 7 MPa for 10 minutes, take it out and cool it, sieve, and sieve out the spherical particles, the surface of the particles is completely covered by copper-aluminum alloy powder, and the supported catalyst is obtained, weighing 210g;

[0051] (2) Configure 400g of 20% NaOH aqueous solution with deionized water, add 80g of the catalyst obtained in step (1), keep the temperature at 85°C, and filter the solution after 4 hours to obtain an activated supported catalyst, and the copper metal loading in the final catalyst It is 45wt%, and after washing to near neutrality, it is stored in deionized water for later use.

Embodiment 2

[0053] (1) Mold nylon-6 (Baling Petrochemical, BL2340-H) with a flat vulcanizer at a temperature of 250°C and a pressure of 7MPa for 10mins to form a sheet with a thickness of about 2mm;

[0054] (2) Get a piece of 20g nylon-6 sheet material, spread one deck copper-aluminum alloy powder on the upper and lower sides of the sheet material, Cu content is 50wt% in the copper-aluminum alloy, and Al content is 50wt%, put into flat vulcanizer, at temperature 220 Molding for 10 minutes under the condition of ℃ and pressure of 7MPa, take out and cool, the upper and lower surfaces of the nylon-6 sheet are covered with copper-aluminum alloy powder, and then the supported catalyst sheet is obtained, weighing 180g;

[0055] (3) The catalyst sheet is mechanically cut into particles with an average particle size of about 3-5mm;

[0056] (4) Configure 20% NaOH aqueous solution 400g with deionized water, add step (3) gained catalyst 80g, keep temperature 85 ℃, filter out solution after 8 hours...

Embodiment 3

[0058] (1) Mold nylon-6 (Baling Petrochemical, BL2340-H) with a flat vulcanizer at a temperature of 250°C and a pressure of 7MPa for 10mins to form a sheet with a thickness of about 2mm;

[0059] (2) Take a 20g nylon-6 sheet, spread a layer of copper-aluminum alloy powder on the top and bottom of the sheet, the Cu content in the copper-aluminum alloy is 45wt%, the Al content is 50wt%, and the Mg content is 5wt%, put it into a flat plate for vulcanization Molded at 220°C and 7MPa for 10 minutes, took it out and cooled it, and the upper and lower surfaces of the nylon-6 sheet were covered with copper-aluminum alloy powder to obtain a supported catalyst sheet, weighing 180g;

[0060] (3) The catalyst sheet is mechanically cut into particles with an average particle size of about 3-5 mm;

[0061] (4) Configure 20% NaOH aqueous solution 400g with deionized water, add step (3) gained catalyst 80g, keep temperature 85 ℃, filter out solution after 8 hours, promptly obtain the loaded c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com