Coiling block stall braking system and hoisting device

A braking system and reel technology, applied in hoisting devices, spring mechanisms, etc., can solve the problems of electrical system failure, electrical system failure, detection speed or motion state consumption, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

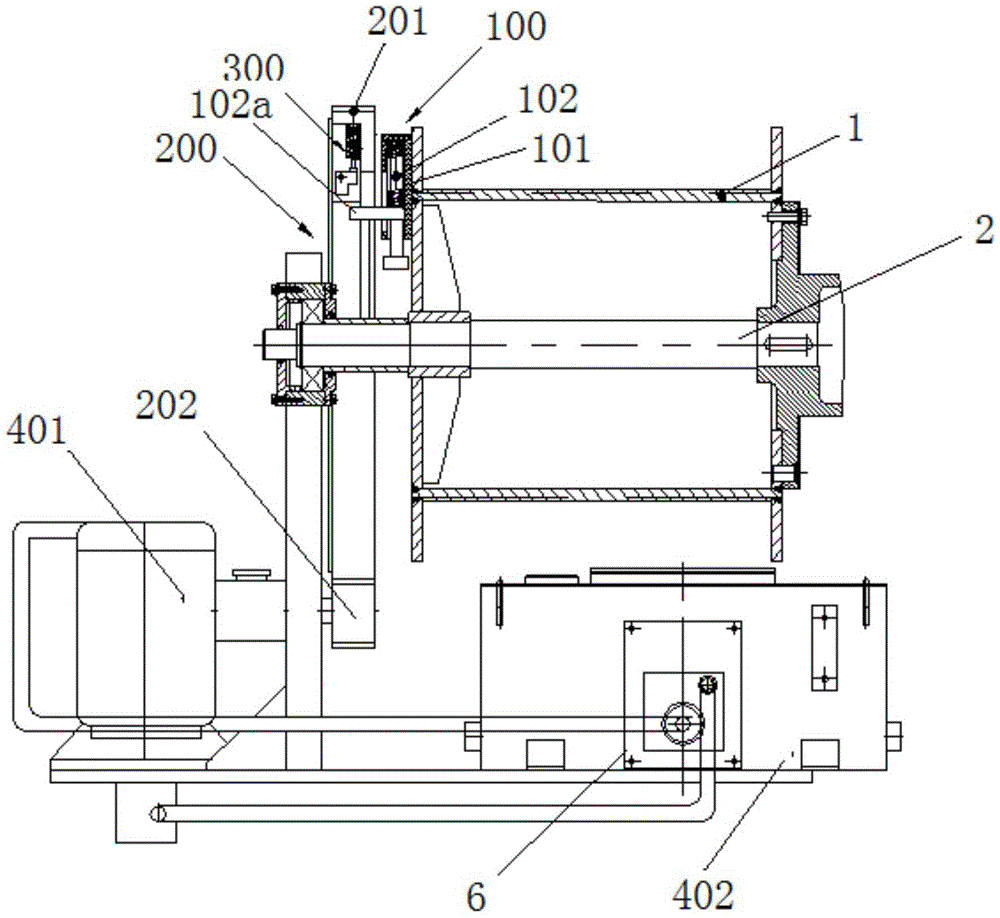

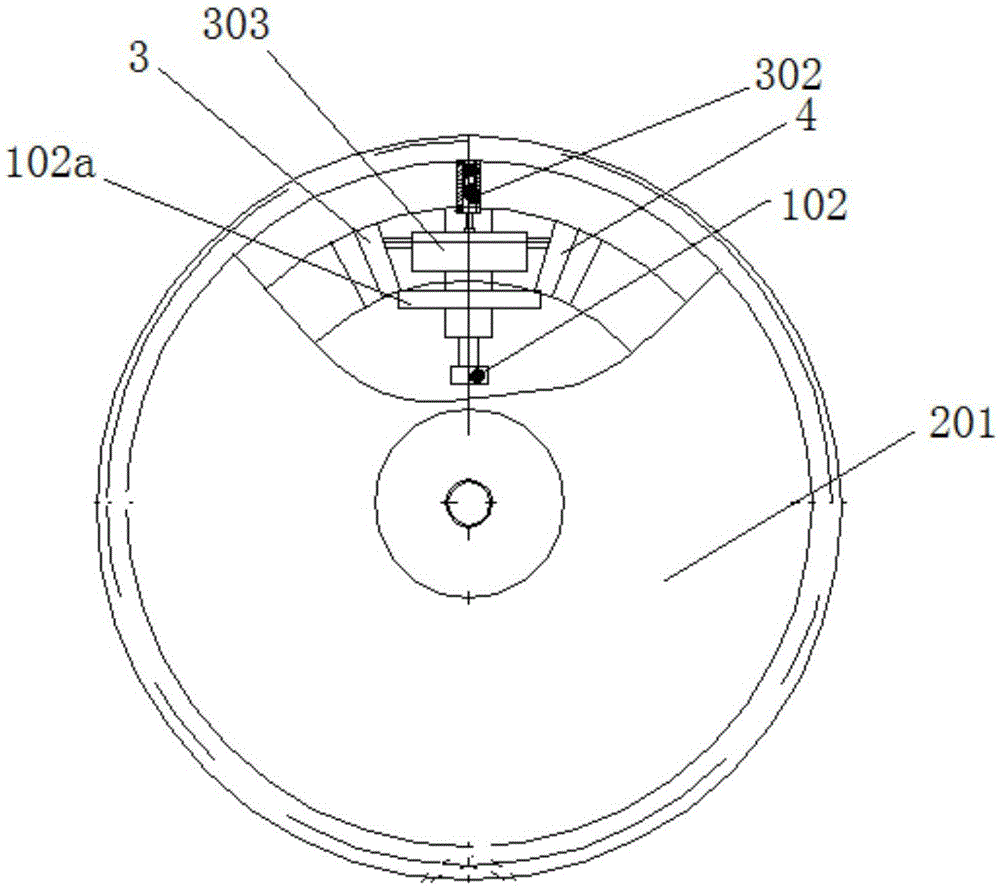

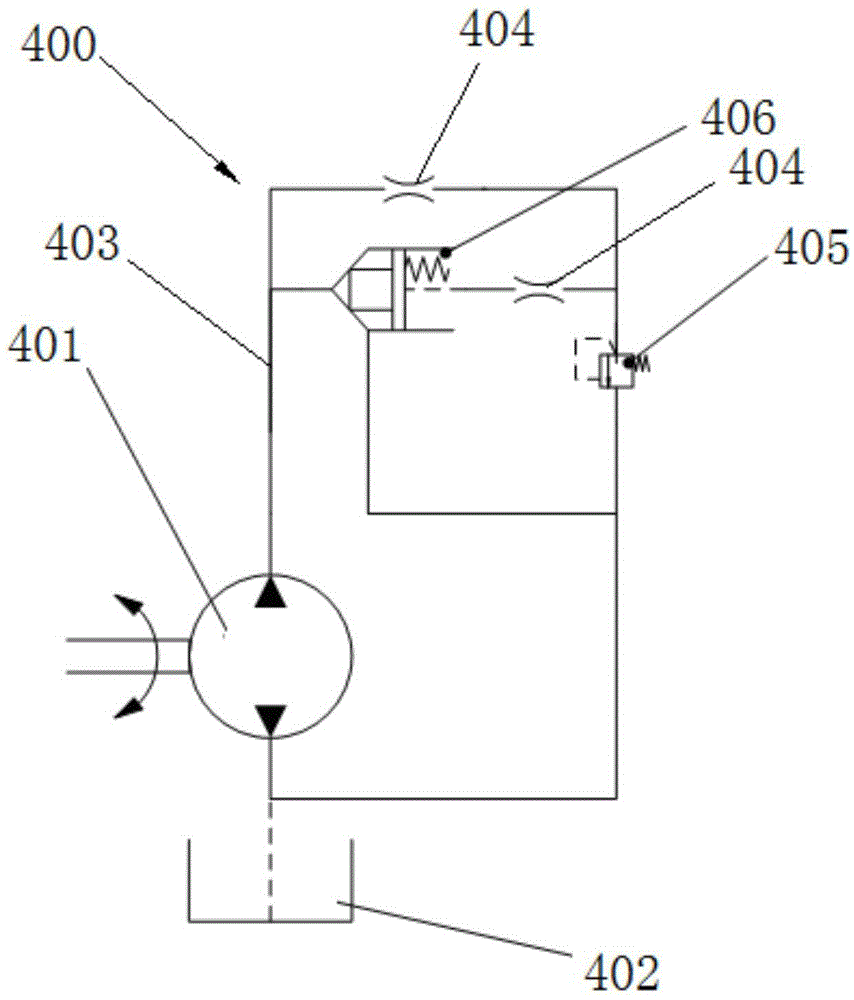

[0047] see figure 1 , according to one aspect of the present invention, a drum stall braking system is provided, wherein the drum stall braking system includes: a centrifugal trigger mechanism 100, the centrifugal trigger mechanism 100 includes a first axial end fixed to the drum 1 A fixed portion 101 and a first sliding portion 102 slidably connected to the first fixed portion 101, a transmission mechanism 200, the transmission mechanism 200 includes a first transmission wheel 201 spaced apart from the axial end surface of the reel 1, the first transmission The wheel 201 is set coaxially with the reel 1, and the first transmission wheel 201 is equipped with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com