A method for measuring 1,6-hexanediol diacrylate content

A technology of hexanediol diacrylate and content, applied in the field of analysis and detection, can solve the problems of inability to meet detection requirements, loss of production enterprises, inability to accurately quantify and other problems, achieve high recovery rate and precision, meet detection needs, and quantitatively accurate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

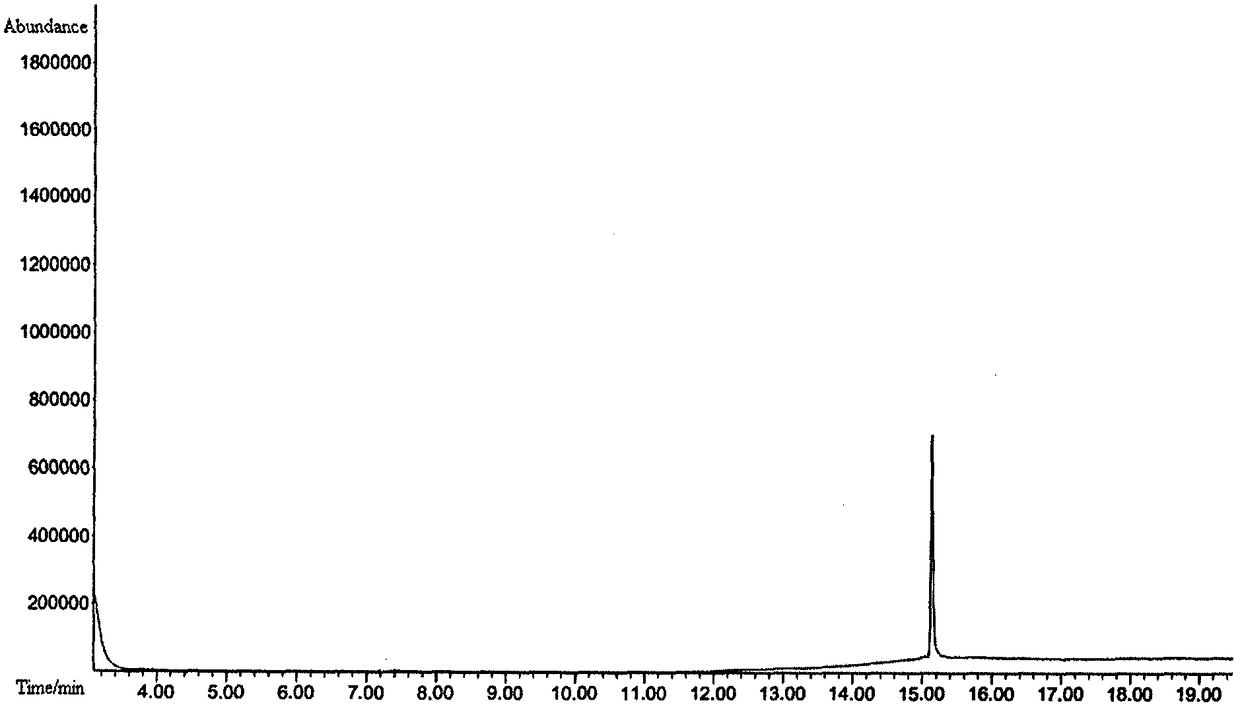

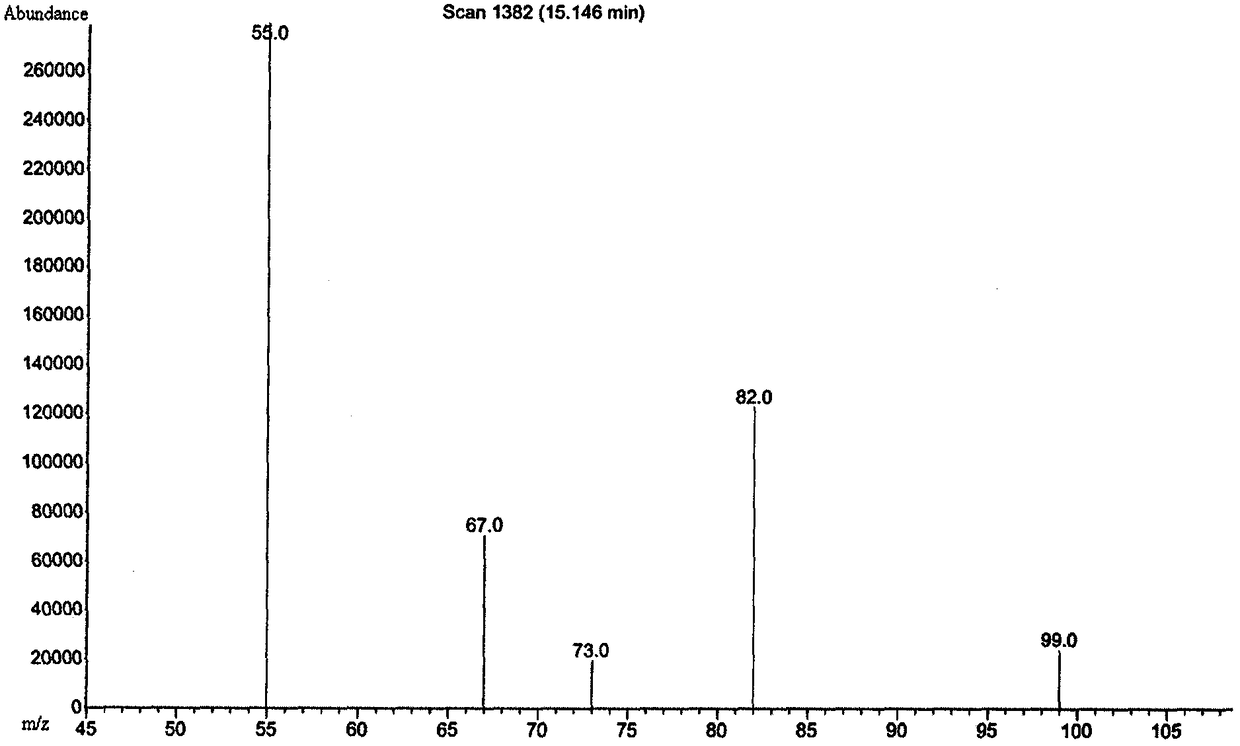

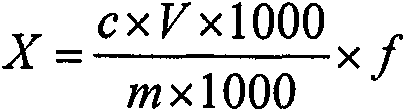

[0029] The mensuration of 1,6-hexanediol diacrylate content in the plastic sample of embodiment 1

[0030] (1) Analysis steps

[0031] Take 50g of plastic samples, first crush them into 1cmx1cmx1cm particles, then use a high-efficiency cutting pulverizer for coarse powder, and then use a high-efficiency cutting pulverizer for low-temperature fine powder. The samples were crushed twice, the first sample was discarded, and the second sample was taken. The pulverized sample powder passed through a standard sieve of 80 or 100 mesh. Weigh 1.0028g and 1.0012g samples respectively in a Soxhlet extractor, add 20mL of dichloromethane-n-hexane mixed solution with a volume ratio of 1:2, perform Soxhlet extraction and reflux at 50°C for more than 4 hours, and after cooling the extract to room temperature, Filtered through a 0.22 μm nylon filter membrane, and the filtrate was analyzed by gas chromatography-mass spectrometry;

[0032] (2) Chromatography and mass spectrometry parameters ...

Embodiment 2

[0039] Embodiment 2 plastic sample 1, the standard substance of 6-hexanediol diacrylate adds and measures

[0040] (1) Analysis steps

[0041] Take the 1,6-hexanediol diacrylate negative sample in Example 1. Weigh six samples of about 1g into a 50mL glass colorimetric tube or Soxhlet extractor, add 0.1mL each of 1000μg / mL 1,6-hexanediol diacrylate standard stock solution, after standing for a period of time, add 20mL volume Dichloromethane-n-hexane mixed solution with a ratio of 1:2, Soxhlet extraction and reflux at 50°C for more than 4 hours, after the extract was cooled to room temperature, filtered through a 0.22 μm nylon filter membrane, and the filtrate was analyzed by gas chromatography-mass spectrometry;

[0042] (2) Chromatography and mass spectrometry parameters

[0043] Gas chromatographic conditions, adopt chromatographic column DB-5MS, 30m×0.25mm×0.25μm, take 60℃ as the initial temperature of the column oven, raise the temperature to 130℃ at a rate of 10℃ / min, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com