Preparing method of carbon nano tube array composite film and heat exchanger

A carbon nanotube array, composite membrane technology, applied in heat exchange equipment, lighting and heating equipment, gaseous chemical plating and other directions, can solve the problems of easy frosting and easy condensation of heat exchanger fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

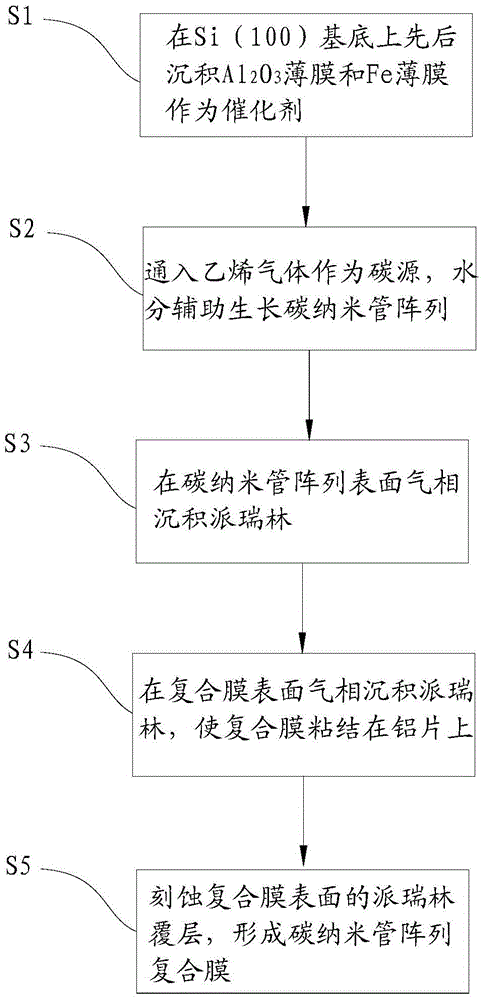

[0022] refer to figure 1 , the method for preparing a carbon nanotube array composite film according to an embodiment of the present invention, the carbon nanotube array composite film includes a carbon nanotube array, a parylene coating and an aluminum sheet, and the aluminum sheet can be a processed fin, It can also be used as raw material for processing heat exchanger fins. The preparation method comprises the following steps:

[0023] S1, put the single crystal silicon (100) substrate into the vacuum chemical vapor deposition equipment, and sequentially deposit Al on the single crystal silicon (100) substrate 2 o 3 The thin film and Fe thin film are used as the catalyst, and the mixed gas of hydrogen and argon is used as the protective gas of the catalyst; among them, Al 2 o 3 The thickness of the thin film is 30-45nm, and the thickness of the Fe thin film is 1.2-1.5nm.

[0024] S2, heat the vacuum chemical vapor deposition equipment to 830-850°C, feed ethylene gas wi...

Embodiment 1

[0033] The preparation method of carbon nanotube array composite membrane comprises the following steps:

[0034] S1, put the single crystal silicon (100) substrate into the vacuum chemical vapor deposition equipment, and sequentially deposit Al on the single crystal silicon (100) substrate 2 o 3The thin film and Fe thin film are used as the catalyst, and the mixed gas of hydrogen and argon is used as the protective gas of the catalyst; among them, Al 2 o 3 The thickness of the thin film was 40 nm, and the thickness of the Fe thin film was 1.4 nm.

[0035] S2, heat the vacuum chemical vapor deposition equipment to 840°C, feed ethylene gas with a flow rate of 100sccm as the carbon source, the feeding time of ethylene gas is 15s, feed water as a weak oxidant, the concentration of water in the vacuum chemical vapor deposition equipment When ethylene gas is thermally decomposed, a carbon nanotube array is grown under the action of a catalyst, and the growth height of the carbon...

Embodiment 2

[0042] The preparation method of the carbon nanotube array composite film is as follows:

[0043] S1, put the single crystal silicon (100) substrate into the vacuum chemical vapor deposition equipment, and sequentially deposit Al on the single crystal silicon (100) substrate 2 o 3 The thin film and Fe thin film are used as the catalyst, and the mixed gas of hydrogen and argon is used as the protective gas of the catalyst; among them, Al 2 o 3 The thickness of the thin film was 30 nm, and the thickness of the Fe thin film was 1.2 nm.

[0044] S2, heat the vacuum chemical vapor deposition equipment to 830°C, feed ethylene gas with a flow rate of 80sccm as a carbon source, the feeding time of ethylene gas is 10s, feed water as a weak oxidant, the concentration of water in the vacuum chemical vapor deposition equipment When ethylene gas is thermally decomposed, a carbon nanotube array is grown under the action of a catalyst, wherein the growth height of the carbon nanotube arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com