Method for manufacturing graphite oxide and apparatus therefor

A graphite and fossil technology, applied in the field of preparation of graphite oxide, can solve the problems of insufficient and effective removal of graphite oxide ions and impurities, achieve excellent dispersion, suppress explosion, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

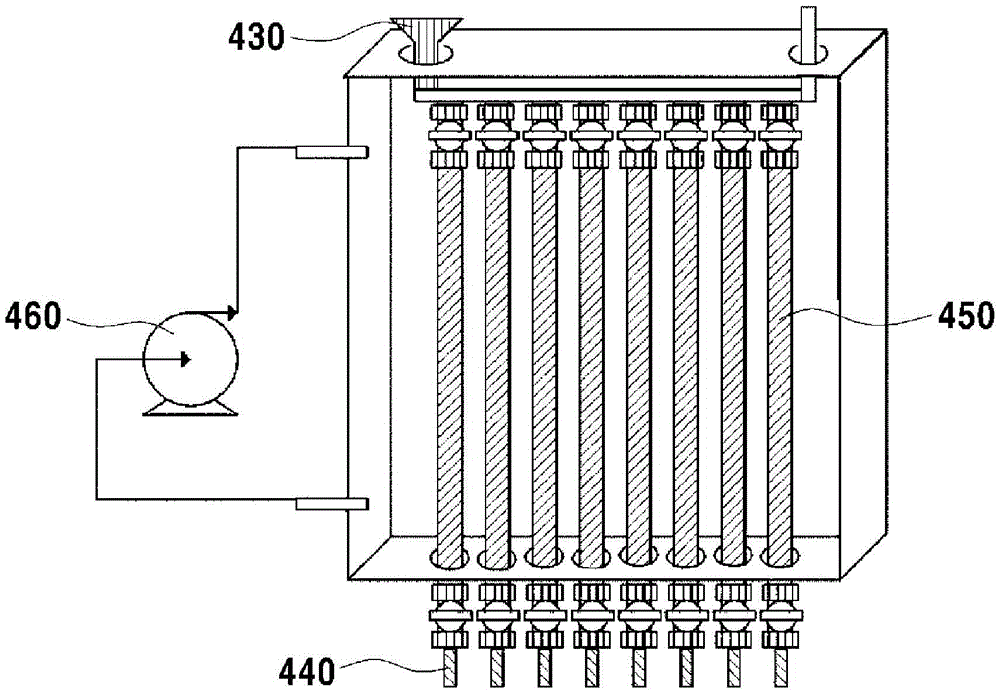

Image

Examples

Embodiment

[0069] In Examples of the present invention, the concentration of remaining metal ions in the prepared graphite oxide was measured by using an inorganic elemental analysis (ICP) method, and then compared. The concentrations of the remaining metal ions in graphite oxide (from which impurities were removed by conventional filter press method or centrifugation) and in graphite oxide (from which impurities were removed by using the filter membrane device of the present disclosure) are shown in Table 1 below. The concentration of the remaining metal ions. In Examples of the present invention, inorganic element analysis was performed by using ICP-AES equipment (iCAP-6000SERIES, Thermoelectron). Pretreatment was performed by using 3 mL of hydrochloric acid, 1 mL of nitric acid, and 1 mL of hydrofluoric acid. Samples containing 0.1 g or more were collected by using Teflon containers. The primary dilution ratio is 25 mL, and the secondary dilution ratio is 50 mL.

[0070] [Table 1] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com