A standard wear part suitable for determining the abrasiveness of rocks in oil drilling formations

An oil drilling and abrasive technology, which is applied in the field of oil drilling rock breaking tools and abrasive grinding, can solve the problem that the metal test piece cannot reflect the wear essence of the diamond drill bit in the rock breaking process, and is not suitable for the determination of rock abrasiveness, test pieces and Rock polishing and other issues, to achieve the effect of ensuring strength, improving heat dissipation effect, and improving the strength of bezel setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

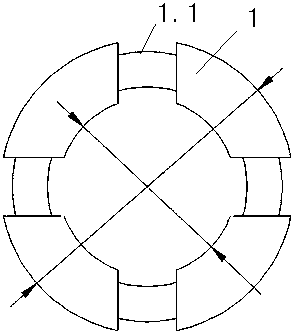

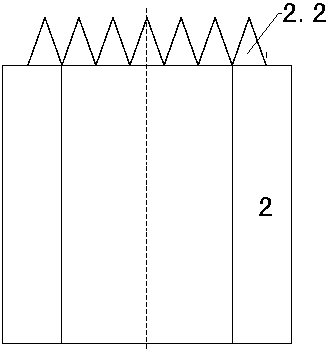

[0026] combined with Figure 1-4 , to further describe the present invention:

[0027] A standard wearing part suitable for the determination of the abrasiveness of rocks in oil drilling formations mentioned in the present invention has a technical solution: it includes a grinding part 1 and a steel body connecting part 2, the grinding part 1 is a cylindrical structure, and the top is equipped with A plurality of water tanks 1.1, the outer diameter of the grinding part is 25 mm, the height is 5 mm, the thickness of the lip surface is 5 mm, the width of the water tank is 5 mm, and the internal and external gap between the grinding part 1 and the steel body connecting part 2 is 1 mm, the steel body connecting part 2 is a cylindrical structure with a zigzag structure 2.1 on the top and an external thread 2.2 on the bottom, which cooperates with the grinding component 1 through the zigzag structure 2.1 on the top; wherein, the grinding component 1 is made of matrix material and ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com