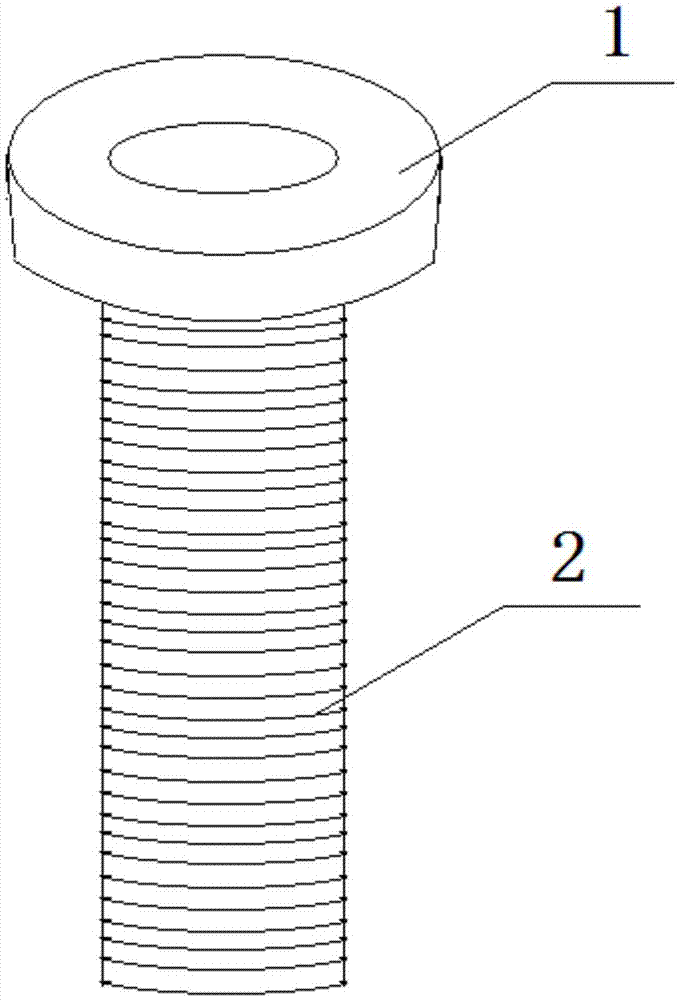

Long nut

A long nut and screw technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems affecting production, transportation and use, reducing the overall quality of equipment, and high material costs, achieving high plasticity and toughness, high Strength and stiffness, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of three-layer layered porous SiC ceramic / alloy steel composites:

[0040] According to the raw material ingredients described in upper surface layer, intermediate layer and lower surface layer respectively (the raw material composition of upper surface layer and lower surface layer silicon nitride ceramics is 94% Si 3 N 4 and 6%Y 2 o 3 , The raw material composition of the intermediate layer silicon nitride ceramics is 3% SiO 2 (particle size 0.1-0.5μm), 1% carbon black (particle size 60-80nm), 7% Y 2 o 3 (particle size is 0.2-1.2μm), balance Si 3 N 4 (α>95%), the ingredients are impregnated with an organic carrier and sintered at 0.4MPa nitrogen pressure and 1730°C for 1h to obtain dry powders of the upper surface layer, the middle layer, and the lower surface layer;

[0041] The dry powders of the upper surface layer, the middle layer and the lower surface layer are deposited in sequence, and finally press-molded under a pressure of 3.5 MPa to obta...

Embodiment 2

[0048] Preparation of three-layer layered porous SiC ceramic / alloy steel composites:

[0049] According to the raw material ingredients described in upper surface layer, intermediate layer and lower surface layer respectively (the raw material composition of upper surface layer and lower surface layer silicon nitride ceramics is 92% Si 3 N 4 and 8%Y 2 o 3 , The raw material composition of the intermediate layer silicon nitride ceramics is 4% SiO 2 (particle size 0.1-0.5μm), 1.5% carbon black (particle size 60-80nm), 5% Y 2 o 3 (particle size is 0.2-1.2μm), balance Si 3 N 4 (α>95%), the ingredients were impregnated with an organic carrier and sintered at 1740°C for 2 hours under a nitrogen pressure of 0.5MPa to obtain dry powders of the upper surface layer, the middle layer, and the lower surface layer;

[0050] The dry powders of the upper surface layer, the middle layer and the lower surface layer are deposited in sequence, and finally press-molded under a pressure of ...

Embodiment 3

[0057] Preparation of three-layer layered porous SiC ceramic / alloy steel composites:

[0058] According to the raw material ingredients described in upper surface layer, intermediate layer and lower surface layer respectively (the raw material composition of upper surface layer and lower surface layer silicon nitride ceramics is 95% Si 3 N 4 and 5%Y 2 o 3 , The raw material composition of the intermediate layer silicon nitride ceramics is 2% SiO 2 (particle size 0.1-0.5μm), 1% carbon black (particle size 60-80nm), 8% Y 2 o 3 (particle size is 0.2-1.2μm), balance Si 3 N 4 (α>95%), the ingredients were impregnated with an organic carrier and sintered at 0.4MPa nitrogen pressure and 1735°C for 2h to obtain dry powders of the upper surface layer, the middle layer, and the lower surface layer;

[0059] Lay the dry powder of the prepared upper surface layer, middle layer and lower surface layer in sequence, and finally press molding under a pressure of 4MPa to obtain a three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com