Heat treatment device and method for large steel plate converter shell

A heat treatment device and heat treatment method technology, applied in the field of heat treatment, can solve the problems affecting the accuracy and safe use of the furnace shell, high electric capacity, large temperature gradient stress of the furnace shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

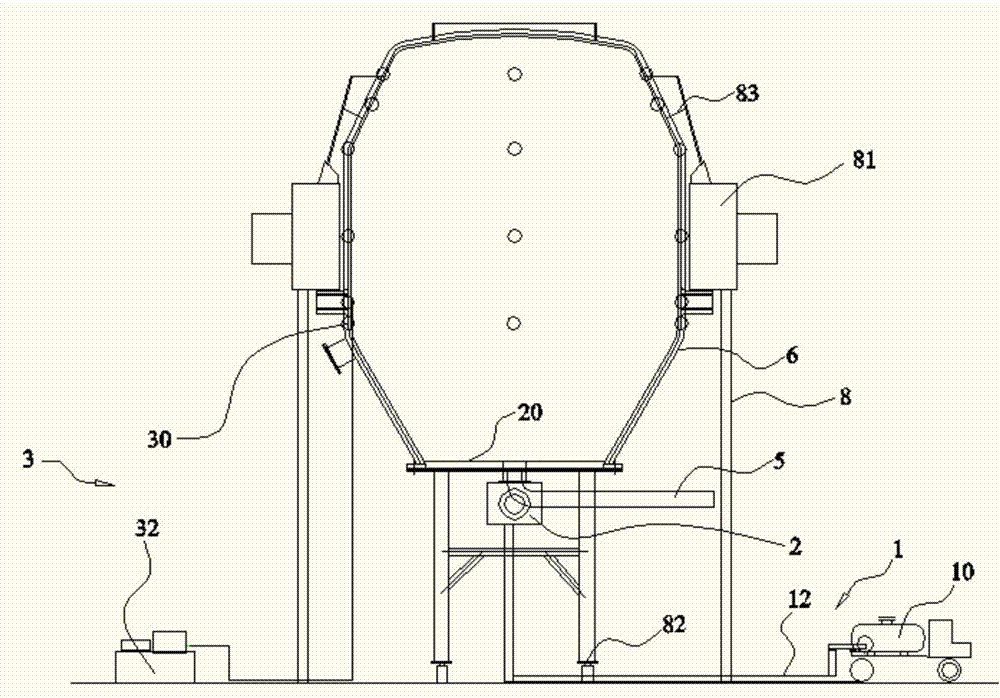

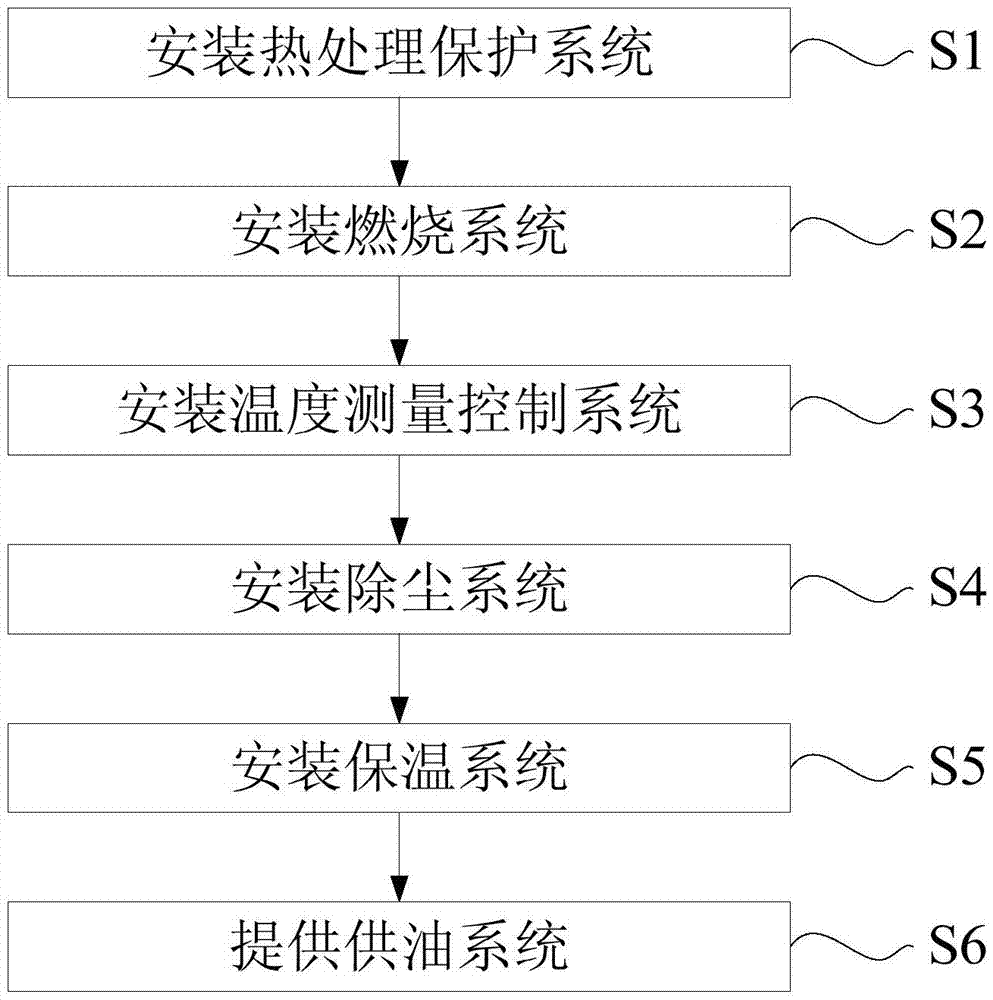

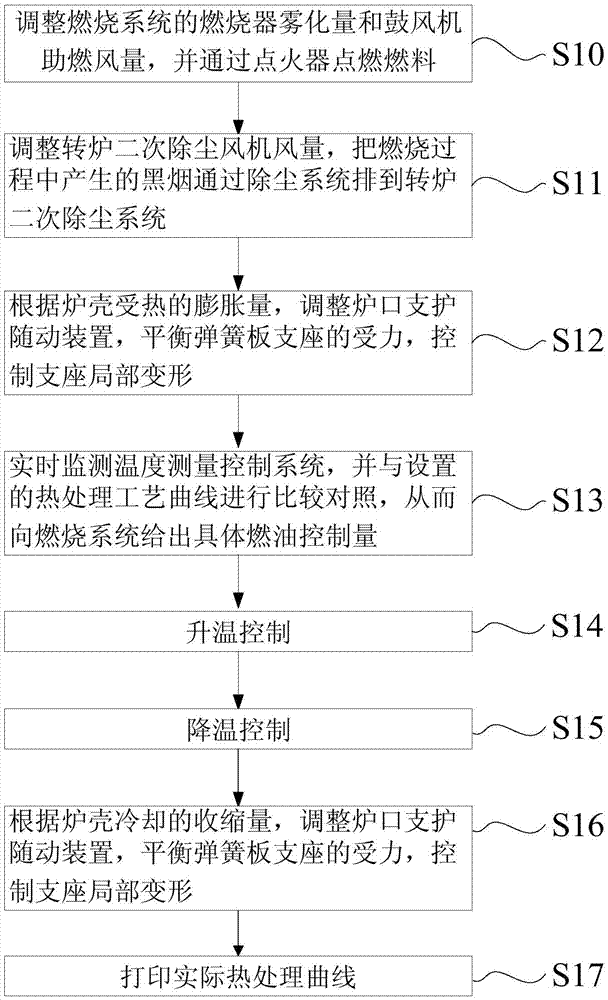

[0055] Please continue to refer image 3 Shown, the present invention is used for the preferred embodiment of the heat treatment method of large-scale converter steel plate furnace shell and comprises the following steps:

[0056] Step S10: Adjust the atomization amount of the burner of the combustion system and the combustion air volume of the combustion air blower, ignite the fuel through the igniter, and do not control the temperature rise rate of the first 300°C.

[0057] Step S11: Adjust the air volume of the dust removal fan of the converter, and discharge the black smoke generated during the combustion process to the secondary dust removal air duct of the converter through the dust removal flue.

[0058] Step S12: According to the thermal expansion of the furnace shell, adjust the supporting device of the converter, balance the force on the spring plate support, and control the local deformation of the support.

[0059] Step S13: Monitor the temperature measurement and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com