Explosive press fitting method for surface-roughened pipes

A surface roughening and pipe material technology, which is applied in the field of explosive compounding, can solve the problems of limited combination of materials that can be compounded, difficulty in ensuring automation and high productivity, and difficulty in making thin and uniform compound layers, so as to achieve a simple and easy-to-operate charge structure , Improve the utilization rate of explosives and reduce secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

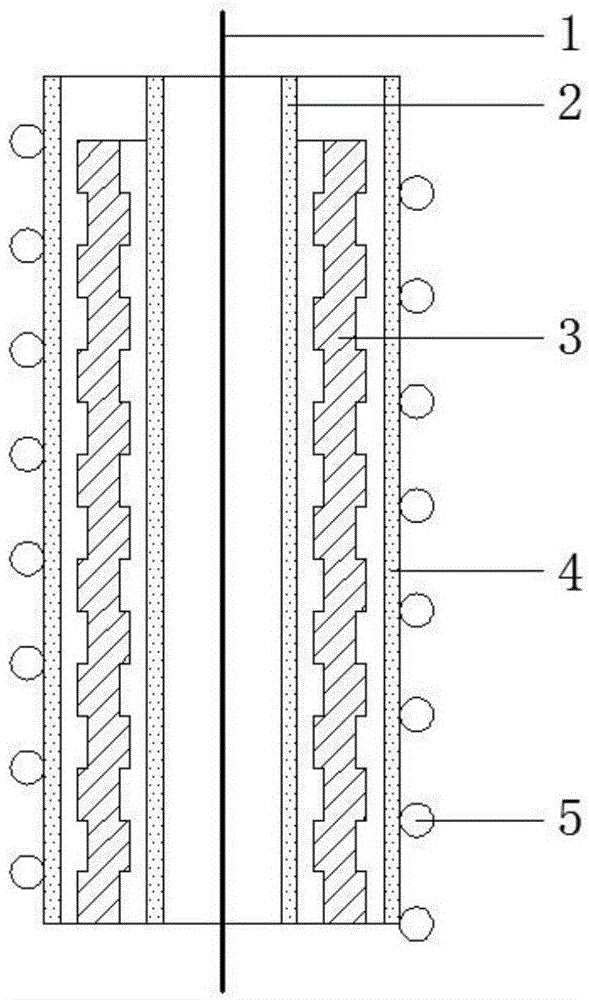

[0028] Such as figure 2 As shown, the ratio of explosive fiber 4 is: 95% RDX / 4% paraffin, the outer diameter is 4mm, and the linear density is 5.0g / m; the inner diameter of ordinary copper tube 3 is 30mm, the outer diameter is 34mm, and the length is 550mm; Q235 seamless steel pipe 2 has an inner diameter of 36mm, an outer diameter of 44mm, a length of 500mm, an outer groove depth of 0.7mm, and a groove width of 7mm; before operation, steel pipes and copper pipes are mechanically polished and treated with 7% dilute hydrochloric acid. After treatment, it is used to remove various surface defects on the composite surface. After obtaining the clean surface to be composited, put the copper pipe 3, steel pipe 2 and explosive fiber 4 into the lower positioning base in sequence according to the figure. The seat is sealed so that water cannot enter the gap formed by the steel pipe and the copper pipe. After each part is installed correctly, the copper-steel composite pipe can be obta...

Embodiment 2

[0030] Such as image 3 As shown, the proportion of implosion fiber 1 is: 96% RDX / 4% paraffin, outer diameter 3mm, linear density 3.0g / m; 6061 seamless aluminum tube 2 inner diameter 28mm, outer diameter 30mm, length 550mm ; Q235 seamless steel pipe 3 has an inner diameter of 32mm, an outer diameter of 38mm, and a length of 500mm, and the depth of the inner and outer grooves is 0.5mm. The width of the groove is 5mm; 550mm; the ratio of the outer winding fiber 5 is: 94% RDX / 4% paraffin / 2% carbon powder, the outer diameter is 2mm, and the linear density is 1.2g / m; Clean up the two walls of the outer wrapping tube 4 and the inner wall of the outer wrapping tube 4, remove floating dust and rust, wipe it clean with acetone or alcohol, and then wrap the outer wrapping fiber 5 evenly on the outer wrapping tube 4 after it is naturally air-dried. The distance between them is kept at 1mm, and the helix angle is adjusted to 25 degrees. After wrapping the required amount of explosive, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com