Functional mobile phone back shell and preparation method thereof

A functional, mobile phone technology, applied in branch office equipment, telephone structure, telephone communication, etc., can solve the problems of microwave signal loss, difficulty in upgrading, high after-sales and maintenance costs, and achieve the effect of anti-acid and alkali guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

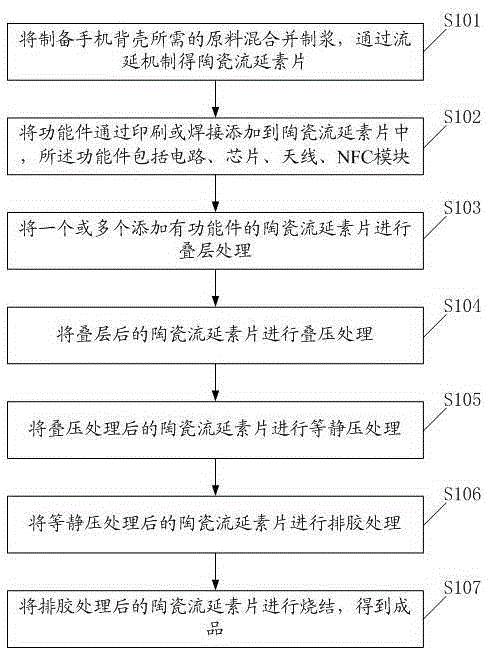

[0040] Such as figure 1 As shown, the present invention provides a method for preparing a functional mobile phone back shell, comprising:

[0041] S101, mixing and pulping the raw materials required for preparing the mobile phone back case, and producing a ceramic cast element sheet through a casting machine, wherein the raw materials required for preparing the mobile phone back case include zirconia, binder, dispersant and plasticizer agent.

[0042] Among them, the raw materials needed to prepare the mobile phone back shell include:

[0043] Zirconia 50-80 parts

[0044] Binder 1-10 parts

[0045] Dispersant 0.1-5 parts

[0046] Plasticizer 0.1-5 parts

[0047] 10-35 parts of solvent.

[0048] The binder is one or a combination of polymethyl acrylate, ethyl cellulose, and polyvinyl alcohol;

[0049] The dispersant is one or a combination of triethanolamine, tributyl phosphate, terpineol;

[0050] The plasticizer is one or a combination of polyethylene glycol, phthala...

Embodiment 1

[0087] (1) Mix 50g of zirconia, 30g of solvent, 10g of binder, 5g of dispersant, and 5g of plasticizer to make slurry, and make a ceramic casting sheet with a thickness of 0.1mm through a casting machine;

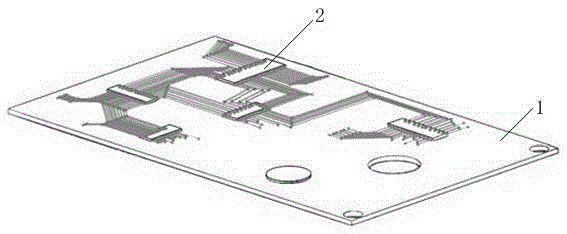

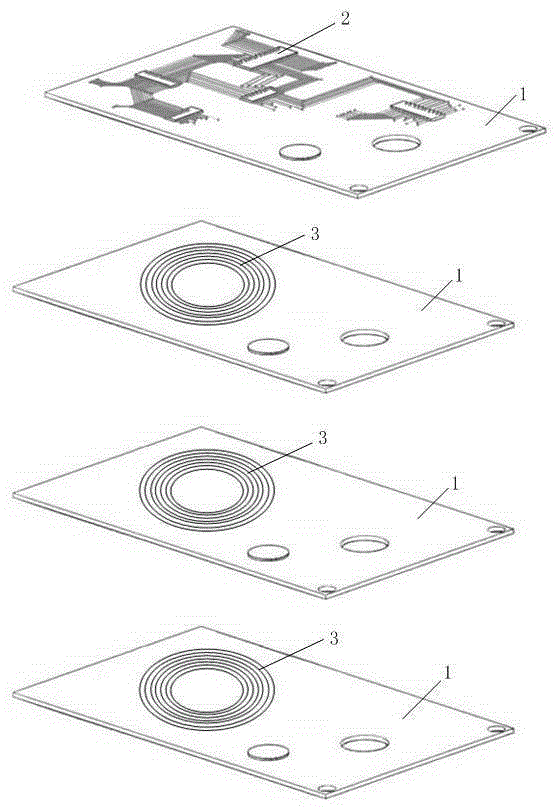

[0088] (2) Add circuits, chips, antennas, and NFC modules to the first layer of ceramic casting sheets by printing or welding, and add coils to the second layer of ceramic casting sheets by screen printing;

[0089] (3) Laminate two layers of ceramic casting sheets;

[0090] (4) Laminating the laminated ceramic casting sheets, the pressure of the press is 10MPa;

[0091] (5) Perform isostatic pressing on the laminated ceramic cast plain sheet, and the pressure of the isostatic pressing is 13Mpa;

[0092] (6) Debinding the isostatically pressed ceramic casting sheet;

[0093] (7) Sinter the ceramic casting plain sheet after debinding treatment, the sintering temperature is 1450° C., and the sintering time is 24 hours, to obtain a finished product with a thickness of 0.2 mm...

Embodiment 2

[0095] (1) Mix 60g of zirconia, 30g of solvent, 5g of binder, 2g of dispersant, and 3g of plasticizer and make slurry, and make a ceramic casting sheet with a thickness of 0.08mm through a casting machine;

[0096] (2) Add circuits, chips, antennas, and NFC modules to the first layer of ceramic casting sheets by printing or welding, and add coils to the second to sixth layers of ceramic casting sheets by screen printing;

[0097] (3) Laminate six layers of ceramic casting sheets;

[0098] (4) Laminating the laminated ceramic casting sheets, the pressure of the press is 12MPa;

[0099] (5) Perform isostatic pressing on the laminated ceramic cast plain sheet, and the pressure of the isostatic pressing is 20Mpa;

[0100] (6) Debinding the isostatically pressed ceramic casting sheet;

[0101] (7) Sinter the cast ceramic sheet after the debinding process, the sintering temperature is 1550° C., and the sintering time is 35 hours to obtain a finished product with a thickness of 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com