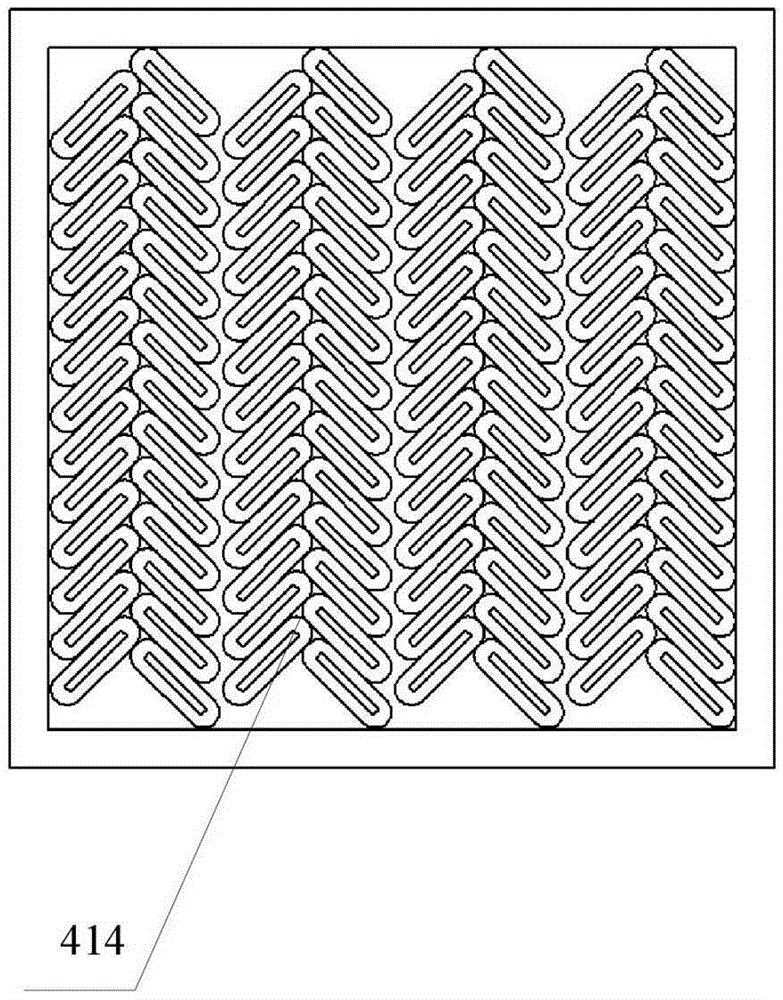

Moving coil magnetic-levitation wireless micro-motion-stage vector circular-arc exchange method and device based on herringbone coil arrangement

A moving coil and micro-moving table technology, which is applied to the exposure device of photo-engraving process, micro-lithography exposure equipment, photo-engraving process of pattern surface, etc. problem, to eliminate the influence of positioning accuracy, to achieve no cable restraint, the effect of the overall compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

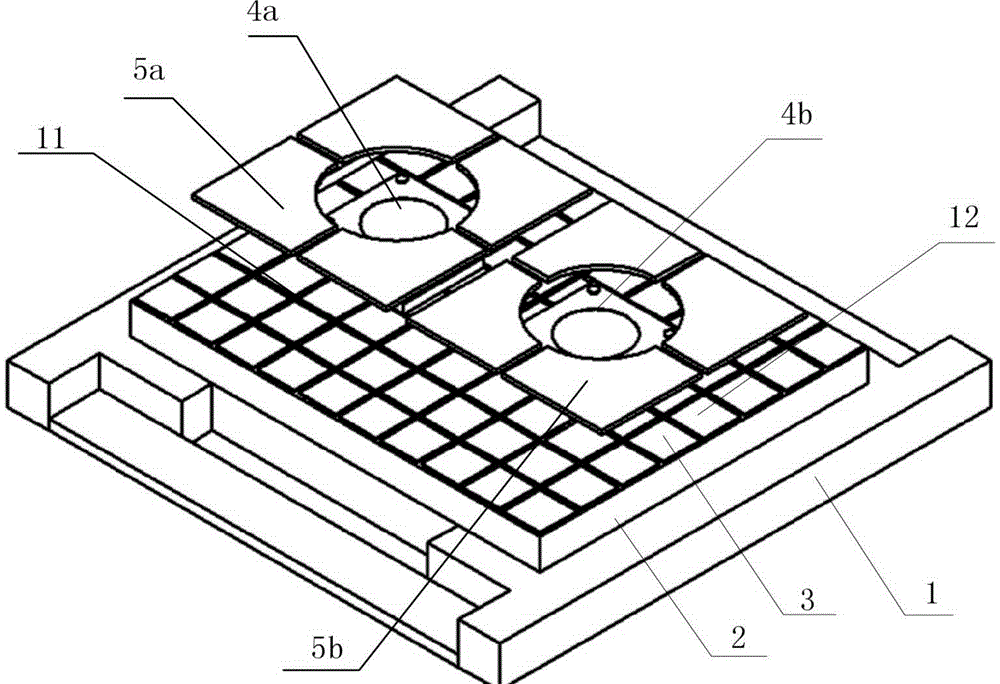

[0023] Below in conjunction with accompanying drawing, embodiment of the present invention is described in further detail:

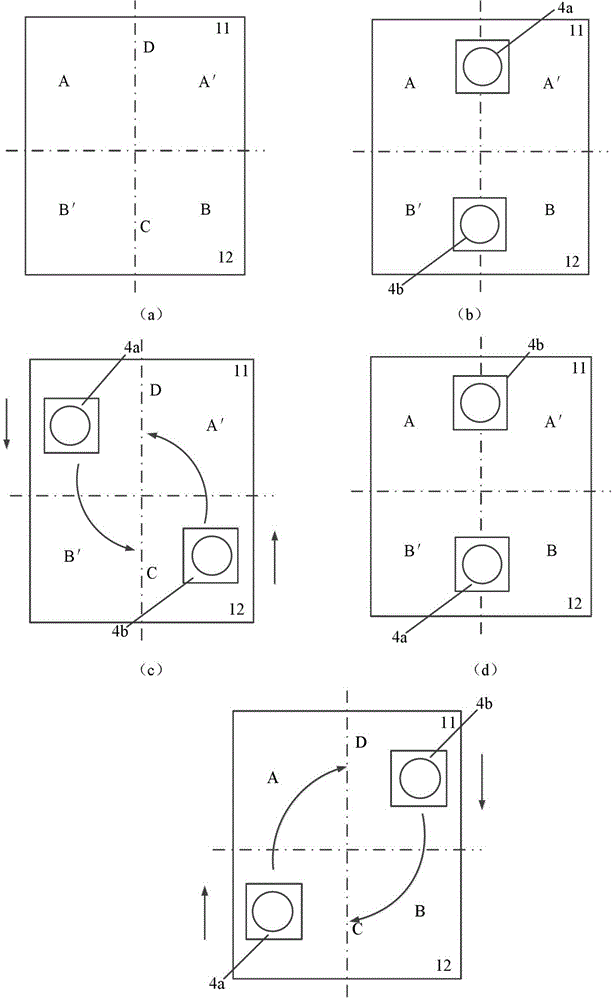

[0024]A moving coil magnetic levitation wireless micro-motion stage vector arc transfer method based on a herringbone coil arrangement, the method includes the following steps: initial working state, the first workpiece stage at the measurement position is in a pre-aligned state, and the exposure position is at the second workpiece The stage is in the exposure state; in the first step, after the pre-alignment of the first workpiece stage at the measuring position is completed, it is driven by the moving coil to move to the predetermined position A of the measuring position for changing the stage and charged and waited. After the exposure of the second workpiece stage at the exposure position, the moving coil Drive and move to the predetermined position B of the exposure position; in the second step, the first workpiece table and the second workpiece table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com