Four-side sealing packaging machine automatic suction bag device

A packaging machine and four-side sealing technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of unreliable high-speed operation, equipment affecting production efficiency, and inability to accurately fall on the climbing belt, etc., to improve work stability, Simple structure and the effect of reducing the number of starts and stops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

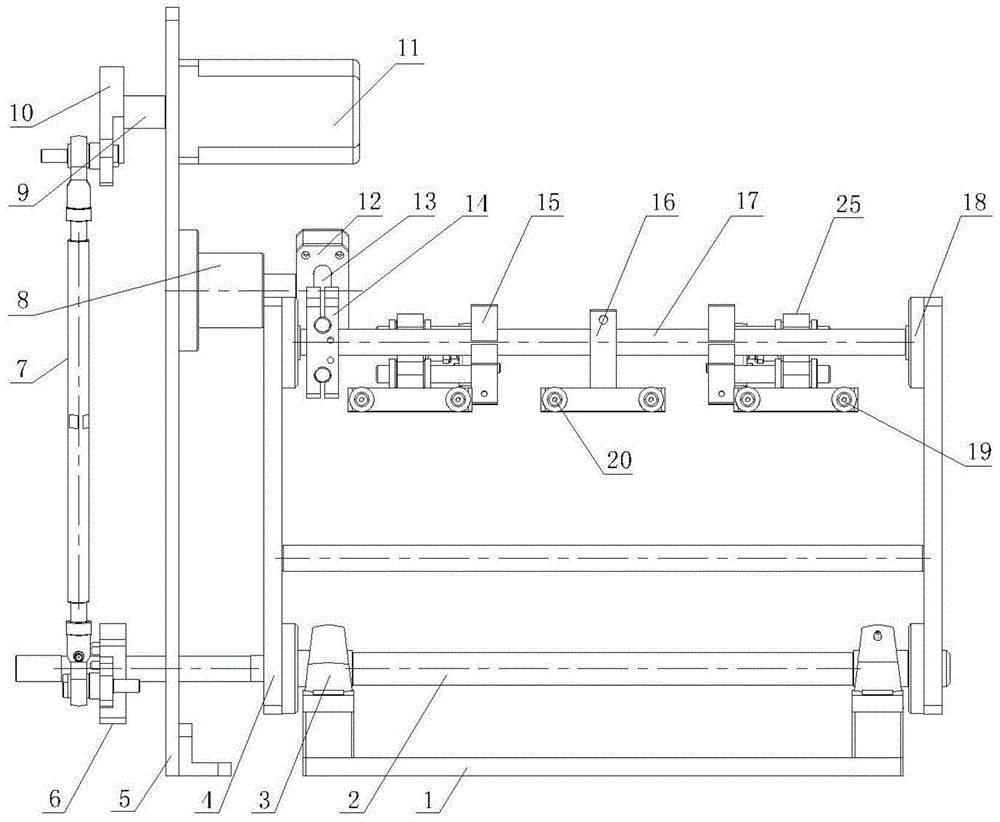

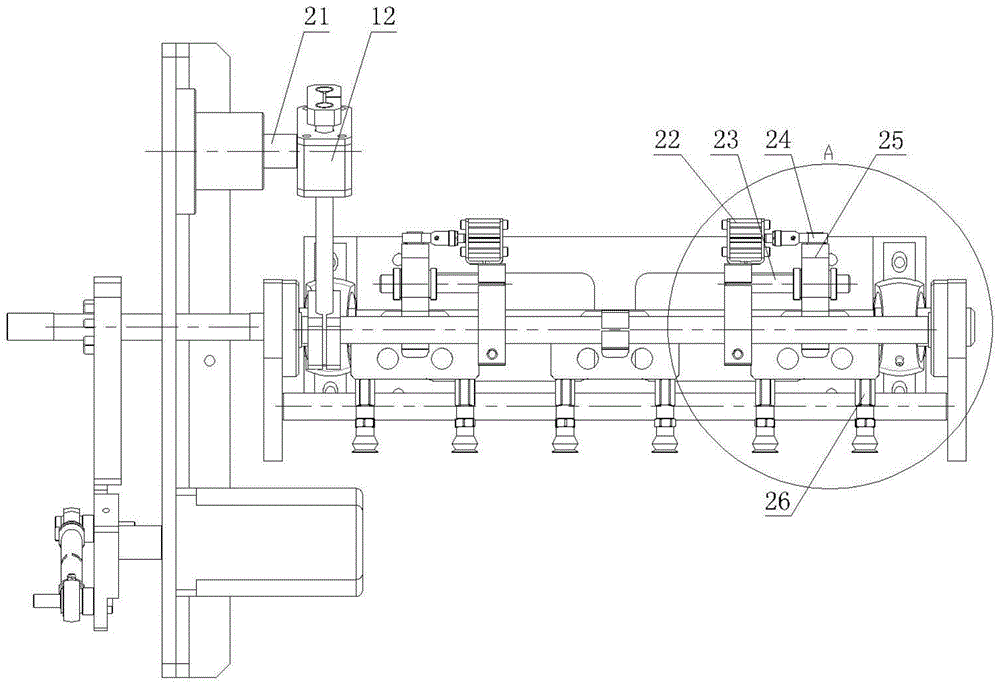

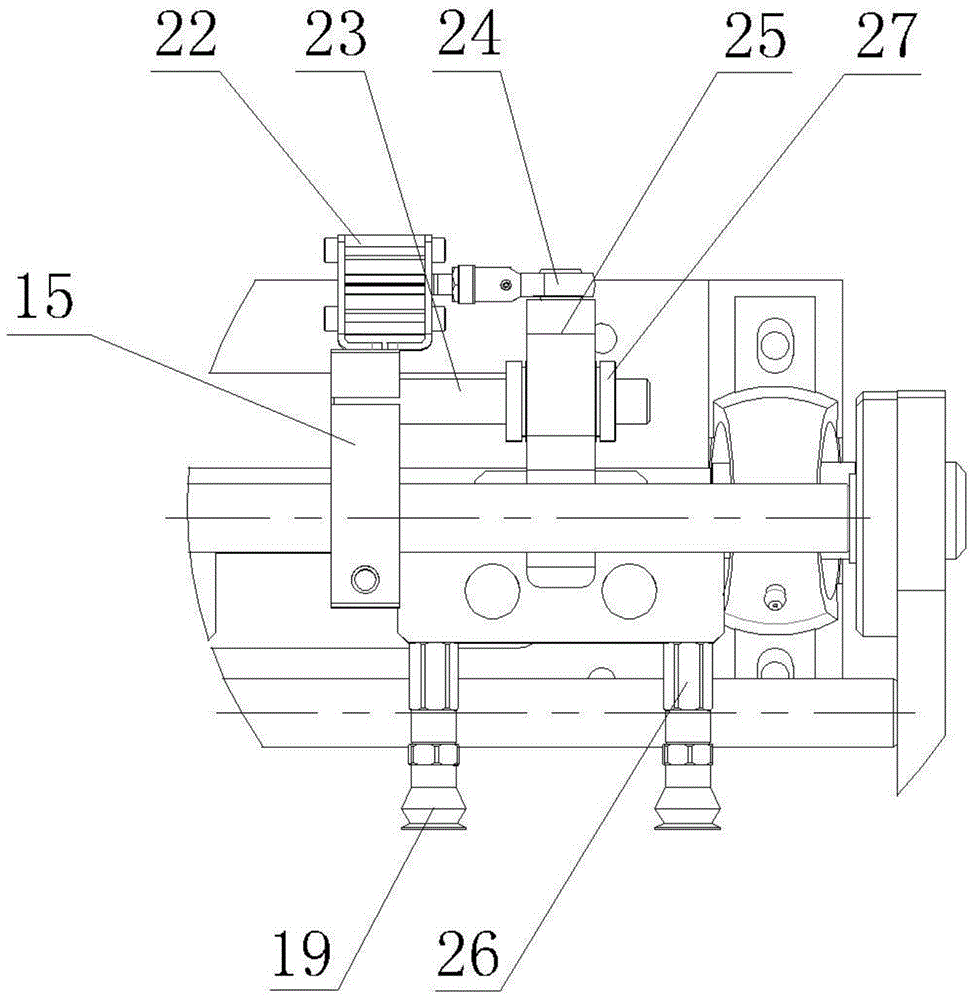

[0020] Such as Figure 1-Figure 4 As shown, an automatic bag suction device for a four-side sealing packaging machine related to the present invention includes a main vertical plate 5 of the four-side sealing packaging machine and a base 1 arranged on one side of the main vertical plate 5, and bearings are symmetrically installed on both ends of the base 1 A seat 3, the bearing seat 3 is preferably a high-center vertical bearing seat, and a rotatable power shaft 2 is installed on the two bearing seats 3 through bearings. On the power shaft 2, a pair of arc-shaped bent plates 4 are installed symmetrically through a key connection on the outside of the two bearing seats 3, and a rotatable steering shaft 17 is installed on the upper end between the pair of bent plates 4. The steering shaft 17 two ends are installed on a pair of bent plates 4 by flange 18 and bearing. A connecting shaft 28 is fixedly connected in the middle between a pair of bent plates 4 .

[0021] A sucker fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com