Floating pipe type falling water noise reducing support frame

A support frame and floating tube technology, which is applied in the direction of sounding equipment and instruments, can solve the problems of different buoyancy, loud noise, unreasonable design of the buoyant support frame, etc., and achieves stable distance, uniform buoyancy, and good levelness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

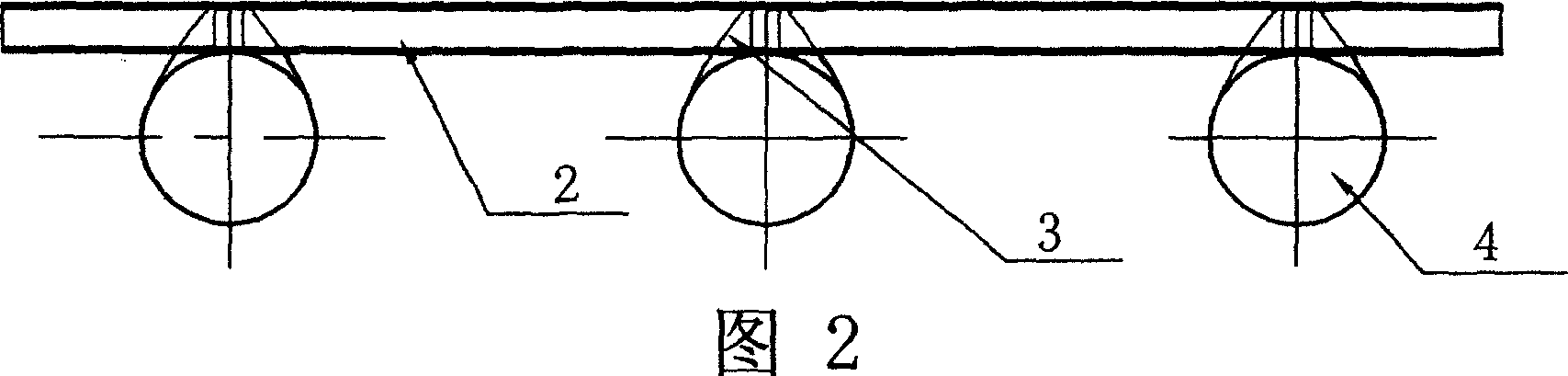

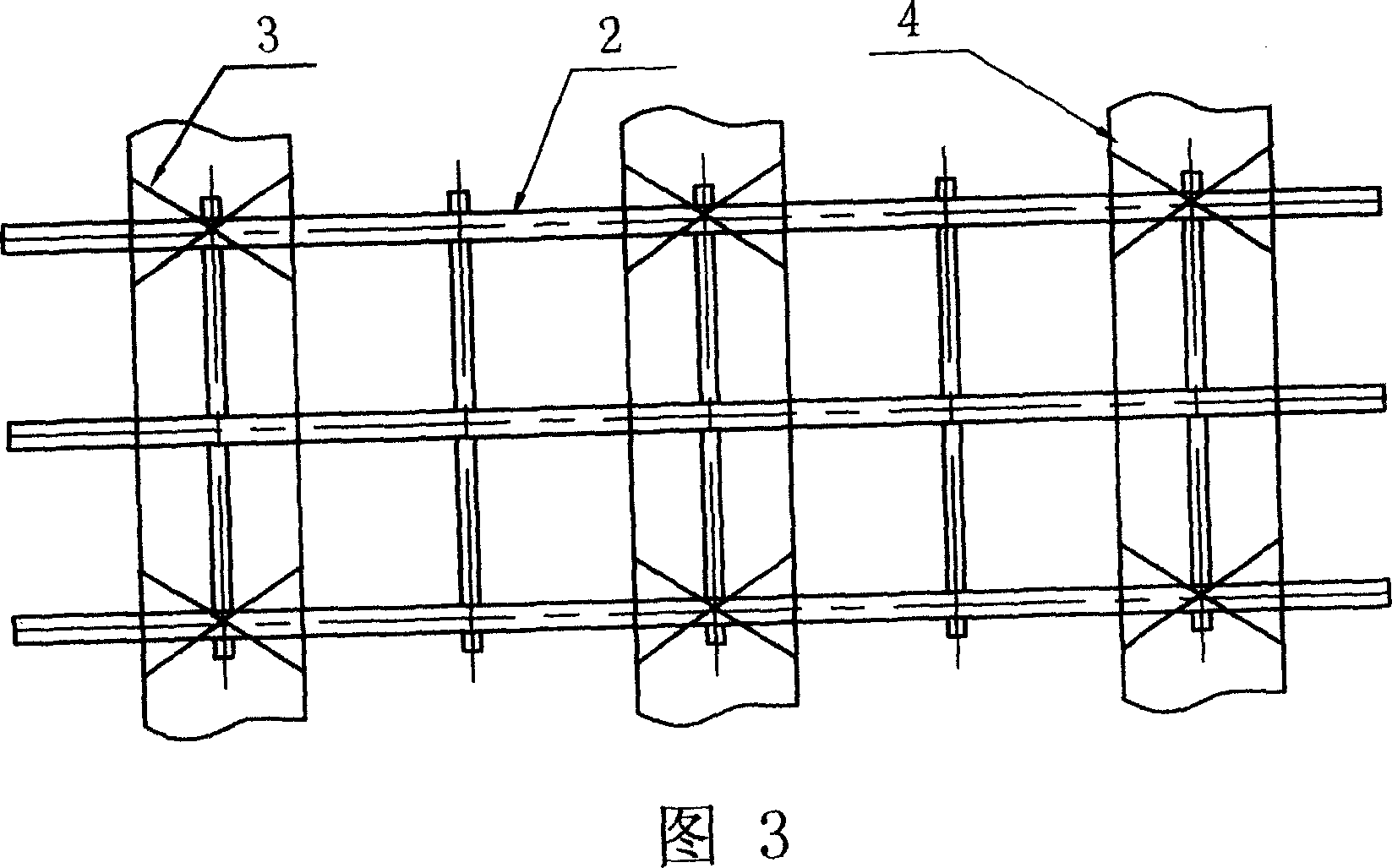

[0014] Example 1: The floating pipe falling into the water noise reduction support frame, as shown in Figures 2 and 3, it consists of a grille frame 2, a fastening belt 3 and a floating frame 1, and the floating frame 1 is composed of several circular The hollow floating tubes 4 are arranged and combined in parallel intervals. Several circular hollow floating tubes 4 are evenly distributed on the lower end of the grid frame 2. The grid frame 2 is fixed on the circular hollow floating tubes 4 by the fastening belt 3. superior.

example 2

[0015] Example 2: In the above example, the floating frame 1 consists of several circular hollow floating tubes 4 arranged in a grid shape, and the grid frame 2 is fixed on the floating frame 1 by fastening belts 3 .

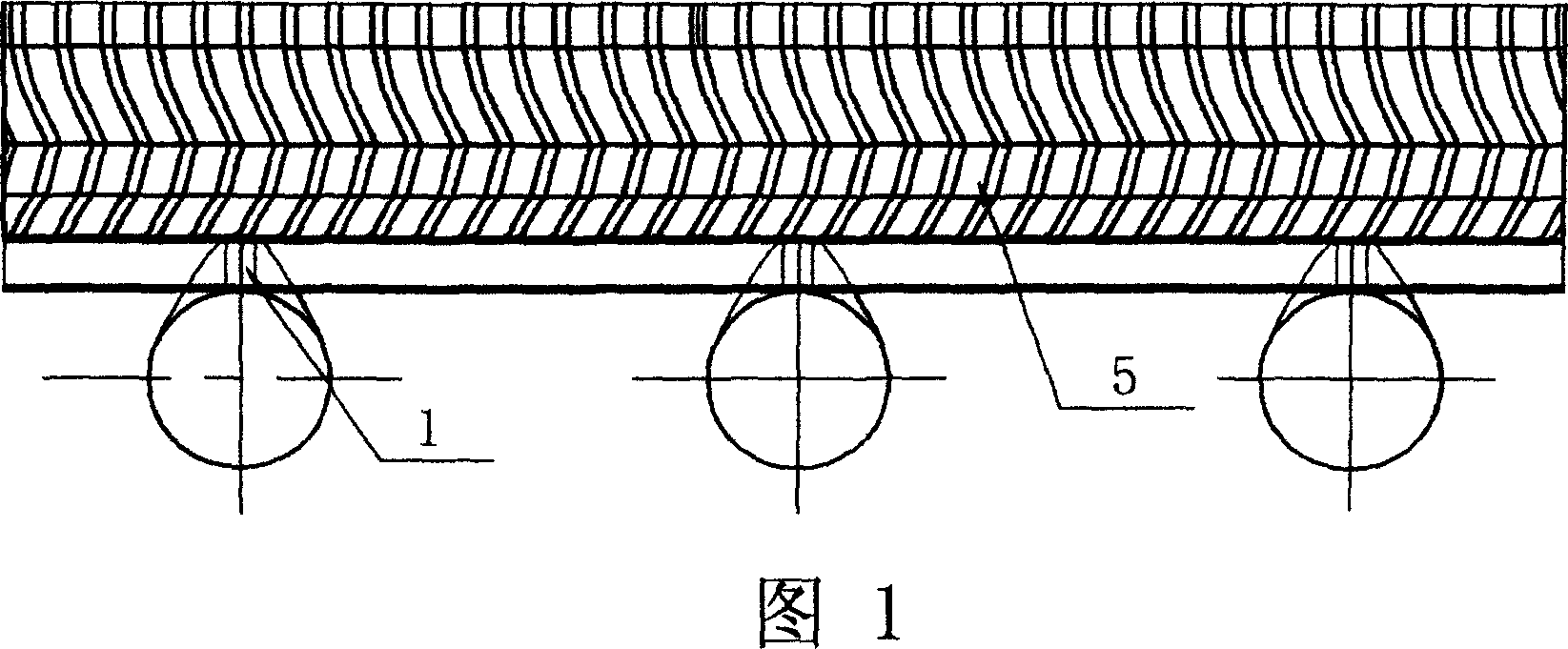

[0016] Its use method is as follows: just place the falling water noise reduction board 5 on the floating frame 1, as shown in FIG. 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com