A marine heavy fuel oil purification heating system

A heating system and heavy fuel oil technology, applied in the charging system, fuel heat treatment device, liquid fuel feeder, etc., can solve the problems of furnace tube coking, unreasonable structure, ignition, etc., to extend service life, improve The effect of purifying the quality and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

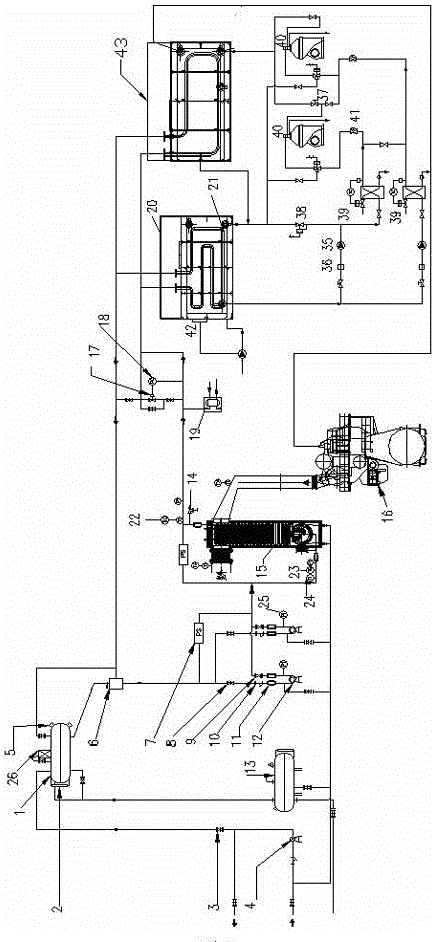

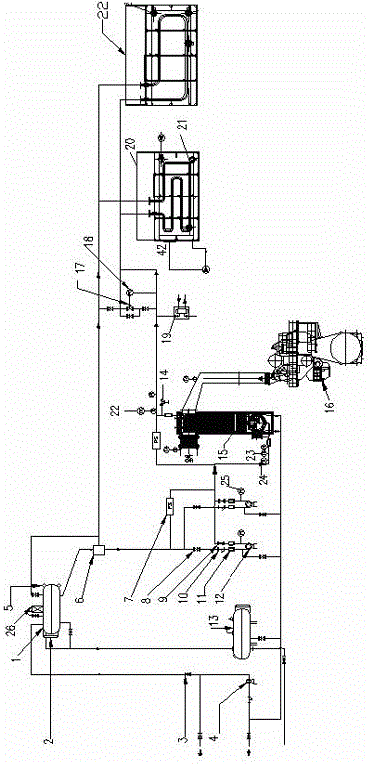

[0063] Such as figure 1 As shown, the present invention discloses a marine heavy fuel oil purification and heating system, which includes: a heavy oil thermal oil circulation heating system and a heavy oil purification system connected to the heavy oil thermal oil circulation heating system by pipelines.

[0064] Such as figure 2 As shown, the heavy oil thermal oil circulation heating system includes a boiler 15, a heavy oil settling tank 20, a heavy oil daily tank 43, an oil-gas separator 6, and a thermal oil circulation pump 12 which are sequentially connected by pipelines and form a loop. The heat transfer oil is circulated in the heavy oil thermal oil circulation heating system.

[0065] The heat transfer oil is circulated in the loop of the heavy oil hot oil circulation heating system. As a heat medium without phase change, the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com