Ladle furnace (LF) refining steel ladle sealing device and use method thereof

A closed device and ladle technology, which is applied in the field of smelting devices, can solve problems such as short residence time, environmental pollution, and large calcium burning loss, and achieve the effects of avoiding secondary oxidation, protecting the environment, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

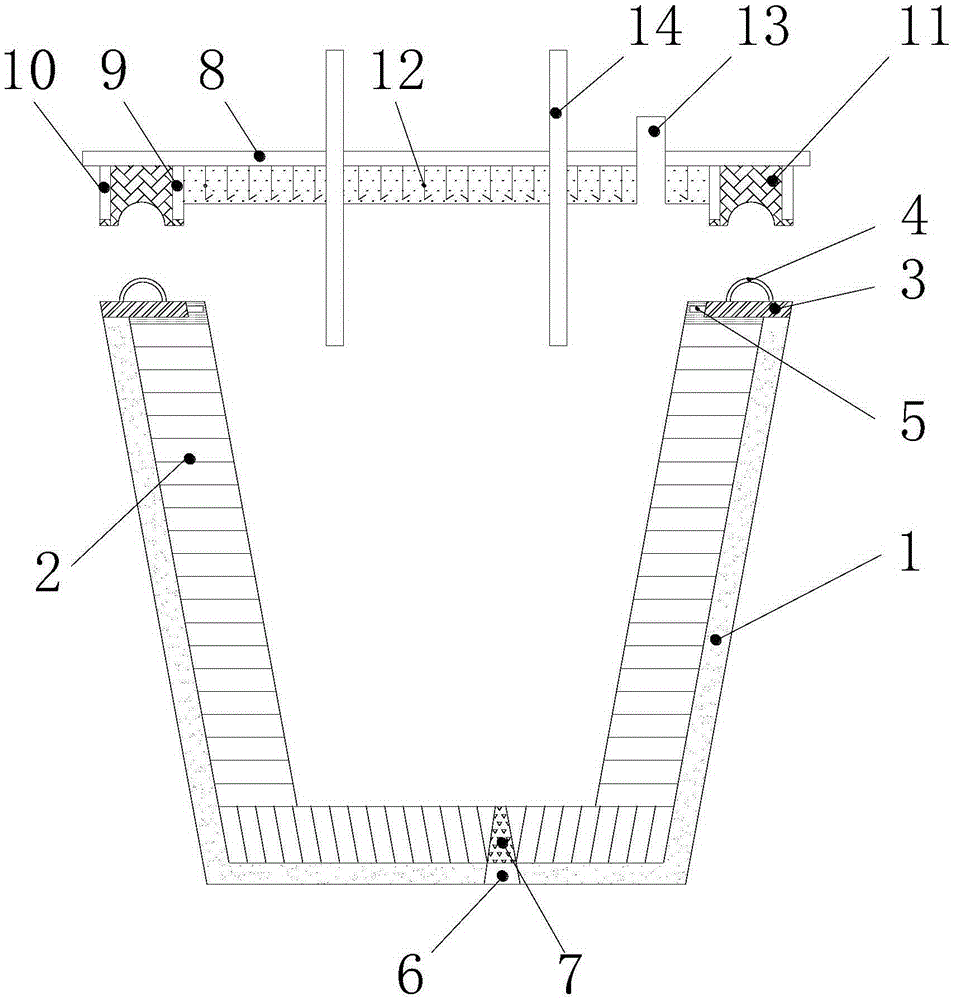

[0045] Embodiment 1: as figure 1 As shown, a kind of LF refining ladle closing device described in the embodiment of the present invention includes a cladding body and a cladding cover;

[0046]The enclosure includes an enclosure 1 and an inner lining layer 2 formed by stacking refractory bricks; the inner lining layer 2 is arranged on the inner bottom and inner side wall of the enclosure; Attached to the air inlet 6 is a porous brick 7 which is of the same height as the bottom lining layer; the argon gas blown into the ladle passes through the hole.

[0047] The first annular steel plate 3 is welded and fixed on the outer edge of the top of cladding 1, and the first annular steel plate 3 extends to the top of the inner liner, and the width of the first annular steel plate 3 is 10-15mm shorter than the refractory brick on the ladle; A plurality of steel bar bars 5 are welded and fixed in the thickness direction of an annular steel plate 3, and the quantity of the steel bar b...

Embodiment 2

[0051] Embodiment 2: the using method of a kind of LF refining ladle sealing device of the present invention, this method comprises:

[0052] Add molten steel into the bag;

[0053] Install an electric hoist next to the waiting station, and fix the ladle cover on the electric hoist;

[0054] When the ladle car advances or retreats into the waiting position, the ladle cover on the electric hoist moves up and down to cover the ladle cover on the ladle; the second and third annular steel plates welded on the ladle cover are just stuck outside the ladle Along the semi-circular tube, the asbestos filling layer on the ladle cover just presses the semi-circular tube on the ladle, so that the molten steel in the ladle can be sealed by improving the ladle and adding the cover;

[0055] The alloy core wire fed by the wire feeding machine is selected and introduced into two wire feeding tubes. The alloy core wire uses silicon-calcium wire and calcium-magnesium wire; by controlling the w...

Embodiment 3

[0083] Embodiment 3: the application of ladle closed wire feeding method and the selection of calcium magnesium wire:

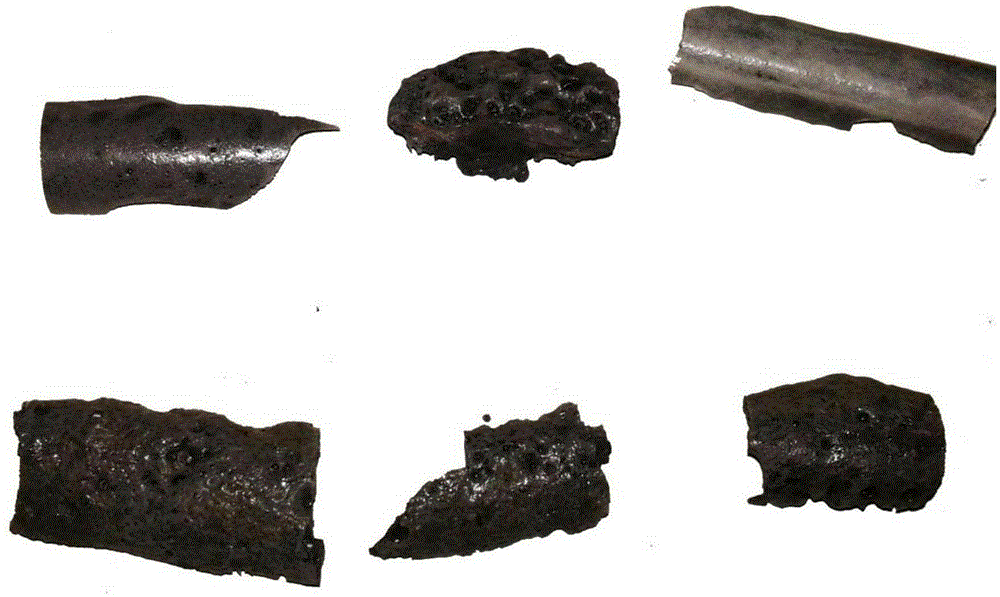

[0084] After the molten steel is refined, it is no problem to feed the silicon-calcium wire to the molten steel to further deoxidize and desulfurize the molten steel, but there are conditions for the denaturation of calcium. When the sulfur in molten steel is 0.010% to 0.015%, there will be CaS is generated; when the sulfur in molten steel is 0.030% to 0.040%, calcium treatment will first generate CaS, which will seriously block the nozzle. From this, we can conclude that the calcified molten steel inside the molten steel forms high-melting-point substances, which are similar to the formation of high-melting-point substances by deoxidizing aluminum. These high-melting point substances must be discharged from the molten steel, otherwise the steel The amount of dissolved oxygen is reduced, but the deoxidized or calcified particles suspended in the molten steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com