Starch-based conductive composite film built on basis of ionic liquid enhanced starch phase change, method and application

An ionic liquid, starch-based technology, applied in the field of conductive polymer composite materials, to achieve the effects of reducing energy consumption, excellent application prospects, and short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

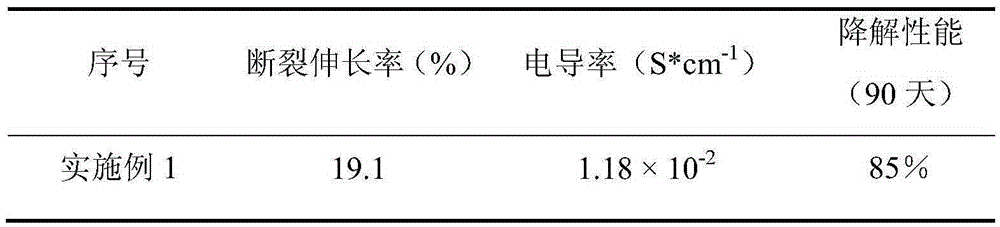

Embodiment 1

[0021] (1) Add an appropriate amount of ionic liquid 1-ethyl-3-methylimidazole acetate to deionized water to obtain an ionic liquid-water solution with a concentration of 0.15:1mol / mol, which is an ionic liquid-water solution according to the quality of dry starch 70% ratio, add cornstarch with a water content of 10%. Based on the strengthening effect of the ionic liquid solution on the disordering of the starch structure, the corn starch-ionic liquid colloidal composite system was obtained after the starch was phase-transformed at 26°C for 1 h.

[0022] (2) Place the colloidal substance of the ionic liquid-water-starch obtained in step (1) on the mold and use a pressure molding machine to form it under a pressure of 6MPa and a temperature of 55°C for 0.5h, and balance it under a 75% humidity environment After obtaining the starch-ionic liquid conductive composite conductive film with a thickness of about 1mm and good transparency (see attached figure 1 ), as can be seen from...

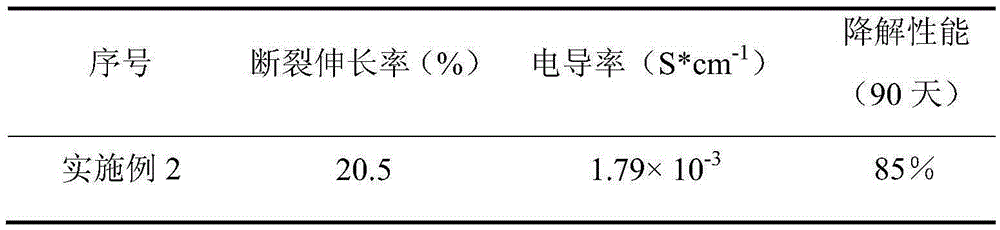

Embodiment 2

[0026] The difference between this embodiment and embodiment 1 is:

[0027] (1) Concentration of ionic liquid-water solution: 0.20:1mol / mol;

[0028] The ratio of dry starch mass to ionic liquid-water solution: 120%;

[0029] Moisture content of potato starch: 18%;

[0030] Strengthening conditions: temperature 32°C, time 1.5h.

[0031] (2) Place the colloidal substance of the ionic liquid-water-starch obtained in step (1) on the mold and use a pressure molding machine to form it under a pressure of 10MPa and a temperature of 45°C for 1.5h, and balance it in a 33% humidity environment Finally, a starch-ionic liquid conductive composite conductive film with a thickness of about 1mm and good transparency was obtained. From the detailed parameters in Table 2, it can be seen that the material has good electrical conductivity, mechanical properties and degradation properties, and presents a good application prospect.

[0032] Table 2

[0033]

Embodiment 3

[0035]The differences between this embodiment and Embodiment 1 are:

[0036] (1) Concentration of ionic liquid aqueous solution: 0.15:1mol / mol;

[0037] The ratio of dry base starch quality to ionic liquid-water solution: 100%;

[0038] Moisture content of tapioca starch: 15%;

[0039] Strengthening conditions: temperature 35 ℃, time 2h.

[0040] (2) Place the colloidal substance of the ionic liquid-water-starch obtained in step (1) on the mold and use a pressure molding machine to mold it under a pressure of 8MPa and a temperature of 65°C for 1h, and equilibrate it under a 33% humidity environment A starch-ionic liquid conductive composite conductive film with a thickness of about 1 mm and good transparency was obtained. It can be seen from the detailed parameters in Table 3 that the material has excellent electrical conductivity, mechanical properties and degradation properties, and presents a good application prospect.

[0041] table 3

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com