Preparation method for carbon-coated super-long titanium dioxide nanotube negative electrode material of lithium ion battery

A lithium-ion battery, titanium dioxide technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as shortening the diffusion distance between lithium ions and electrons, and achieve good electrochemical performance, excellent The effect of improving the rate property and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] During operation, first weigh 1g of P25 powder and disperse evenly in 50mL of 10mol / L sodium hydroxide aqueous solution, stir for 2.5h, then place the mixed solution in the lining of a polytetrafluoroethylene reactor, transfer it to a hydrothermal kettle, and 150 ℃ hydrothermal reaction in an oven for 24h. Then cool to room temperature, take out the liner, pour off the supernatant to obtain a white precipitate, wash with water and centrifuge until the pH of the supernatant is about 7. After washing once with alcohol, the precipitate was dispersed in a petri dish, dried at 80°C for 5 hours, and the powder was collected. Take 1g of the above powder, add 300mL HCl (0.1mol / L), stir magnetically for 1.5h, then wash with water and centrifuge until the supernatant pH is 7, then wash with alcohol and disperse in a petri dish, dry at 80°C for 5h, collect the powder, and obtain the hydrogen radical Titanate Nanotubes (H-TNT).

[0028] Take 0.2-0.5g of H-TNT, dissolve it in abso...

Embodiment 2

[0033] According to the conditions of Example 1, only changing the heating rate to 1° C. / min, anatase nanotubes wrapped with amorphous carbon were obtained. After the battery is assembled according to the method of Example 1, the discharge specific capacity remains 152mAhg after 100 cycles at a current density of 0.5C -1 .

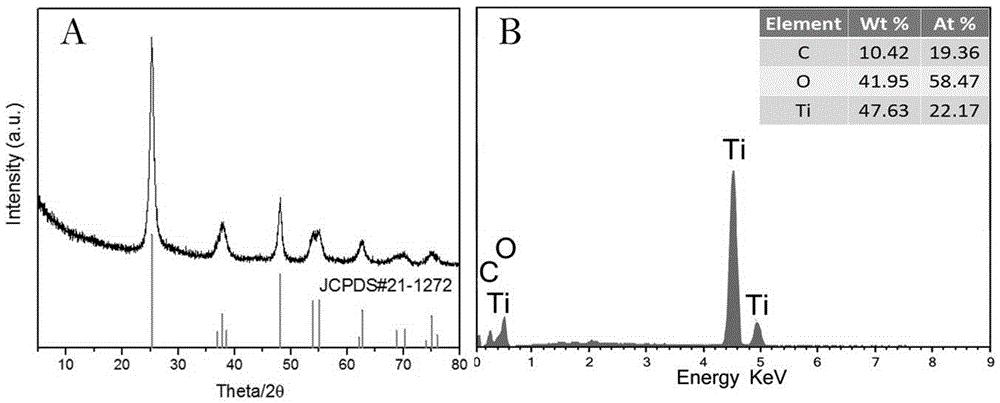

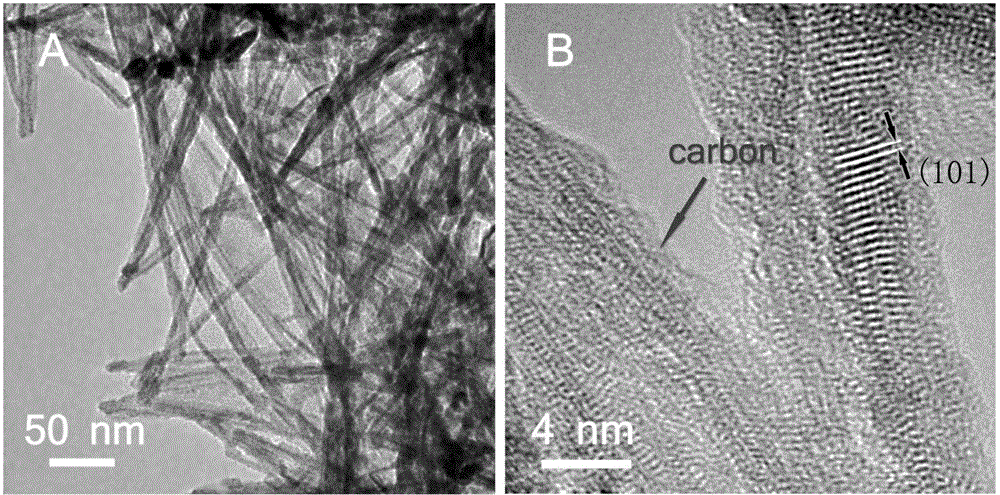

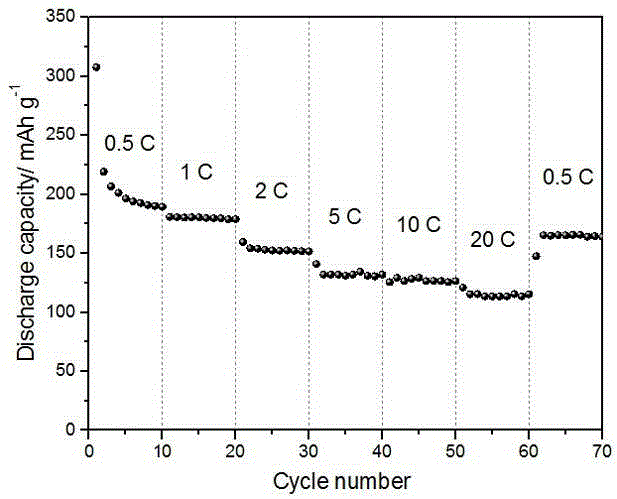

[0034] image 3 For the prepared CTiO 2 Nanotube rate performance diagram, showing excellent rate performance, when the current density reaches 20C, the capacity remains at 126mAhg -1 , when the current density drops back to 0.5C, the current density rises back to 162mAhg -1 , close to the initial value.

Embodiment 3

[0036] According to the conditions of Example 2, only changing the holding temperature to 400 ° C, obtained TiO coated with amorphous carbon 2 Nanotubes, whose crystal form is TiO 2 -B type, after being assembled into a battery according to the method of Example 1, the discharge specific capacity remains at 154mAhg after 100 cycles at a current density of 10C -1, the Coulombic efficiency is close to 100%, as Figure 4 It is shown that the material has excellent electrochemical performance.

[0037] Figure 5 For the prepared CTiO 2 Nanotube rate performance diagram, showing excellent rate performance, when the current density reaches 20C, the capacity remains at 157mAhg -1 , when the current density drops back to 0.5C, the current density rises back to 219mAhg -1 , close to the initial value.

[0038] In summary, a kind of lithium ion battery negative electrode material CTiO of the present invention 2 A method for preparing nanotubes. By synthesizing carbon-coated nanot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com