An experimental evaluation method for the service temperature of superalloy turbine blades

A technology of service temperature and turbine blades, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as quantitative evaluation of degraded tissue, achieve strong engineering application significance and broad prospects, eliminate complex influences, and reliable evaluation results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples will further illustrate the present invention so that those skilled in the art can better understand the advantages and features of the present invention.

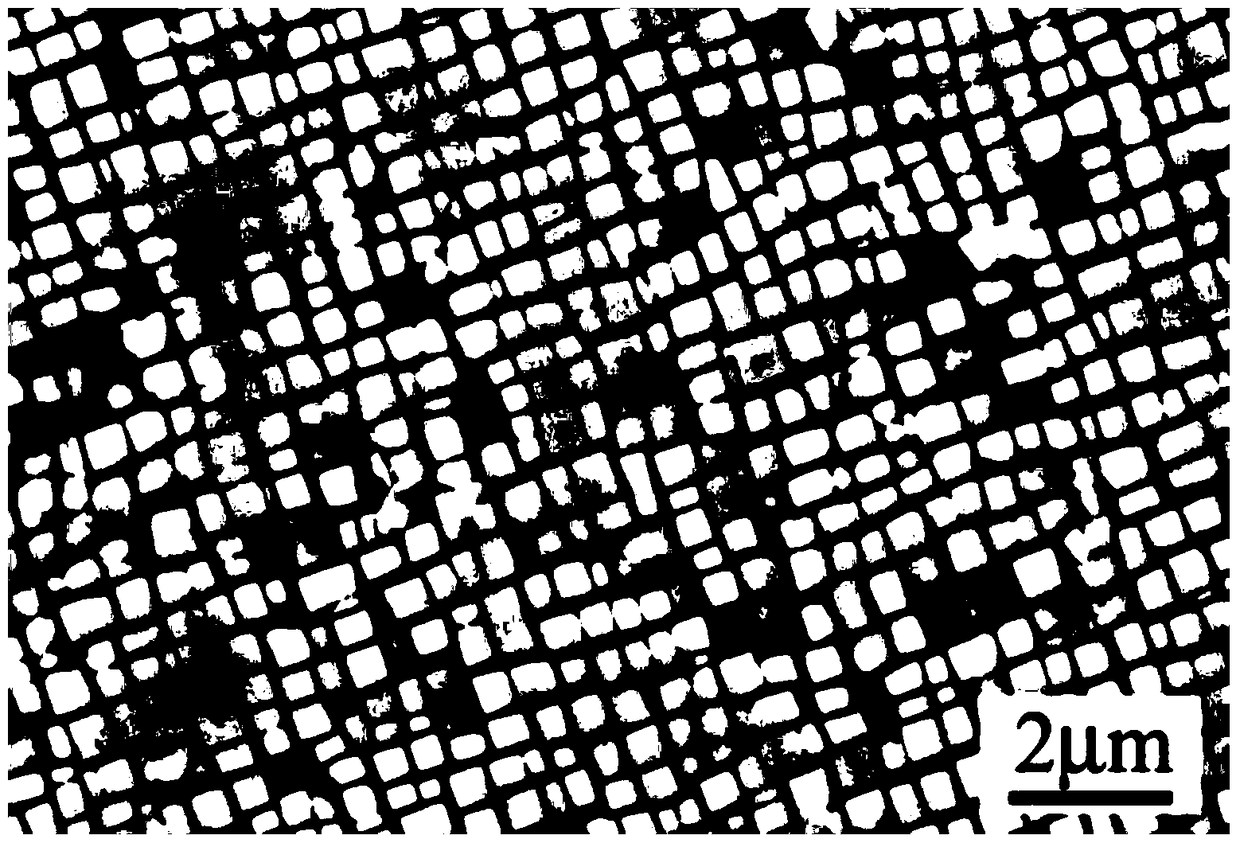

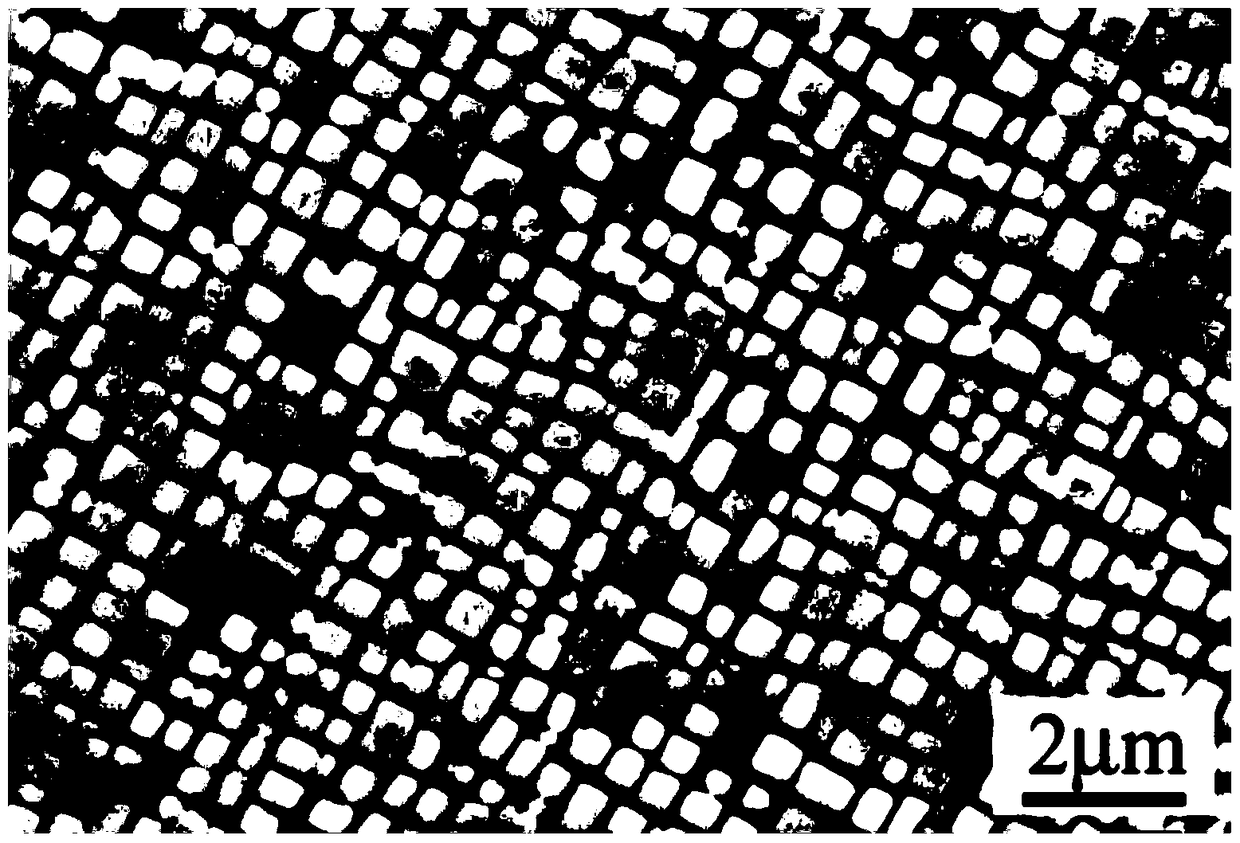

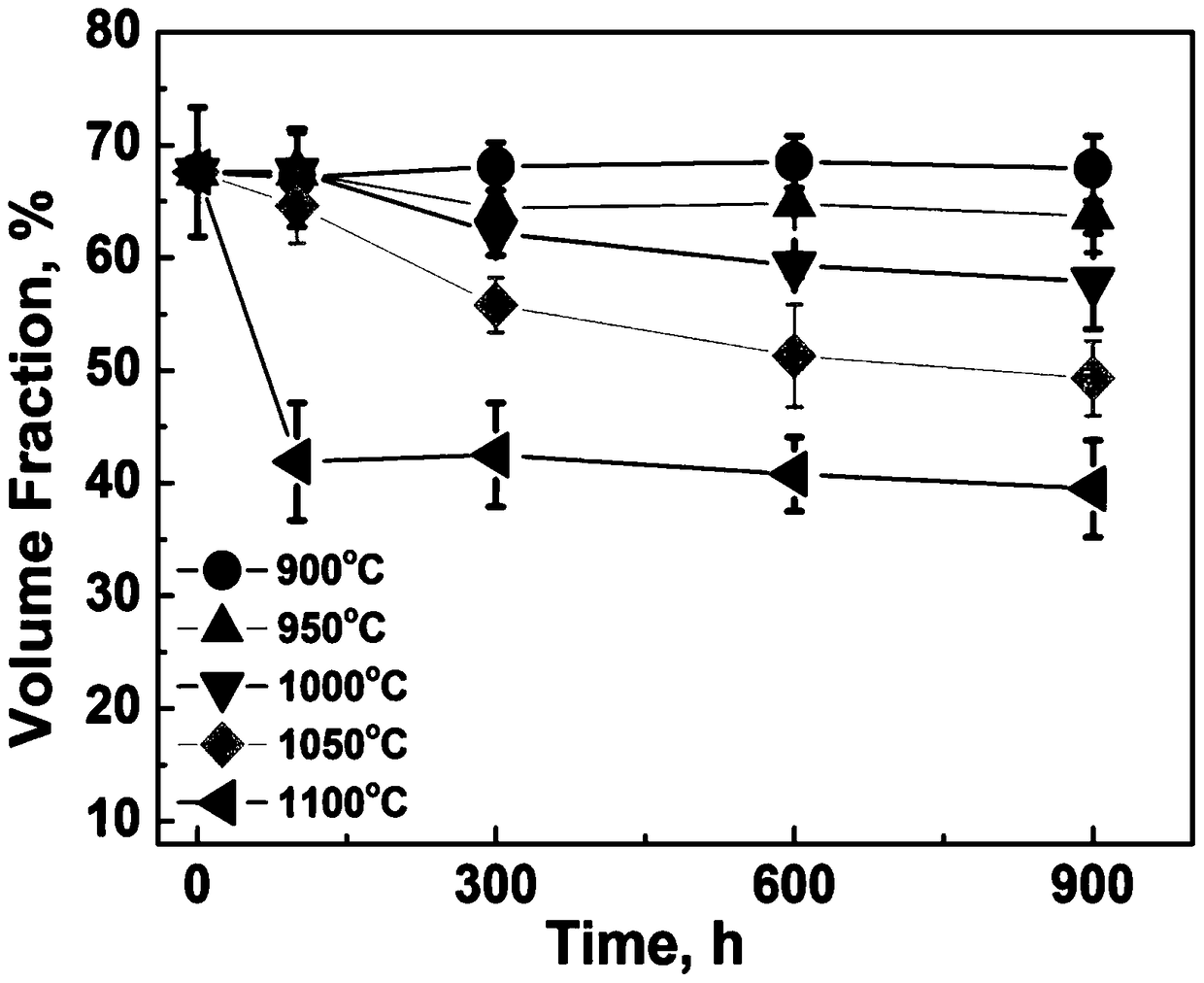

[0021] First, verify whether the original structure of the DZ125 service blade and sheet material DZ125 alloy is similar or consistent. Observing the microstructure of the tenon part of the DZ125 alloy blade and the blade material DZ125 alloy after standard heat treatment, the morphology, size and cubic degree of the γ'phase of the two are very close, respectively. figure 1 and figure 2 Shown. Refer to the grid number point method in GB / T 15749 to quantify the volume fraction of γ'phase. Set 216 grid intersection points. When the intersection point is in the γ'phase, it is counted as 1, when the intersection point is in the γ'phase and the substrate interface, it is counted as 0.5, and when the intersection point is in the matrix, it is counted as 0. The ratio of the above statistical results to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com