Hydrophilic siloxane oligomer, silicon hydrogel, corneal contact lens and preparation method

A siloxane oligomer, corneal contact lens technology, applied in the field of corneal contact lens and preparation, hydrophilic siloxane oligomer, and silicon hydrogel, can solve the problem of low oxygen supply, difficult compatibility, It is difficult to maintain hydrophilicity, so as to achieve the effect of comfortable wearing and good oxygen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

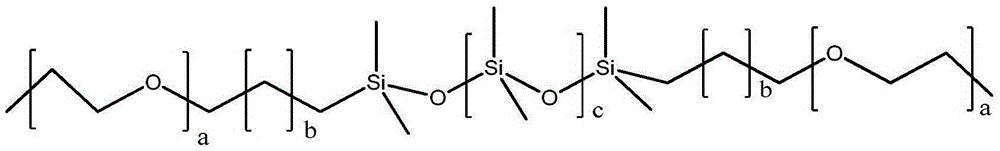

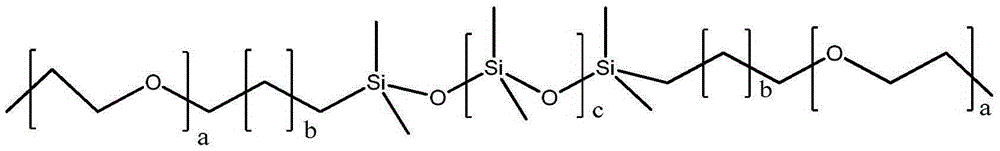

[0048] A kind of hydrophilic siloxane oligomer, the molecular formula of this siloxane oligomer is as follows:

[0049]

[0050] , or for

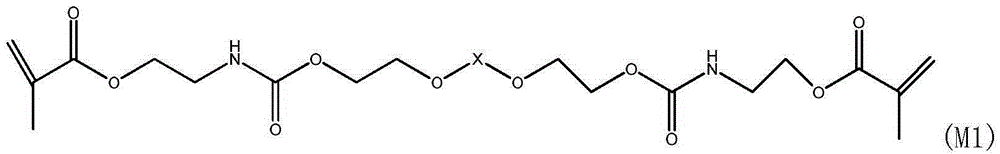

[0051] Wherein, the structural formula of X is as follows:

[0052]

[0053] Wherein, the value range of a is an integer between 10 and 23, the value of b is an integer between 3 and 8, and the value of c is an integer between 3 and 40.

[0054] The molecular formula of the above-mentioned hydrophilic siloxane oligomer has two forms: M1 and M2. There are longer PEG chains at both ends of the siloxane oligomer. Since the PEG chain segment has good hydrophilicity and can be miscible with hydrophilic monomers, the siloxane oligomer can be dissolved without solvent. It has excellent compatibility with hydrophilic monomers. In the case of good mutual solubility, siloxane oligomers can be used to make contact lenses with excellent light transmission.

[0055] The siloxane oligomer in this embodiment is a siloxane tri-block copolymer,...

Embodiment 1

[0066] Take 14.1 g of diol (the structural formula is shown in the following formula w1) and dissolve it in an appropriate amount of dichloromethane in a three-necked flask, then add 3 mL of catalyst dibutyltin dilaurate, and stir magnetically. Dissolve 3.1 g of isocyanoethyl methacrylate (IEM) in dichloromethane, mix well, and drop it into a three-necked flask at room temperature under constant pressure. Then heated to 60 ° C reflux reaction 10h. After the reaction, the obtained liquid was washed with petroleum ether, allowed to stand to separate layers, and the liquid in the lower layer was distilled under reduced pressure to obtain a siloxane oligomer, which was designated as M1-w1. The synthetic equation is shown in the chemical reaction formula of the above-mentioned first method.

[0067]

example 2

[0069] Take 14.1g of diol (the structural formula is shown in the above formula w1), 2.8g of glycidyl methacrylate (GMA), 100 μL of trifluoromethanesulfonic acid, magnetic stirring, reflux reaction at 20°C for 24h, and vacuum distillation after the reaction. The obtained siloxane oligomer is denoted as M2-w1. The synthetic formula is shown in the chemical reaction formula of the above-mentioned second method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com