A clean production process for preparing n-n-butylthiophosphoric triamide

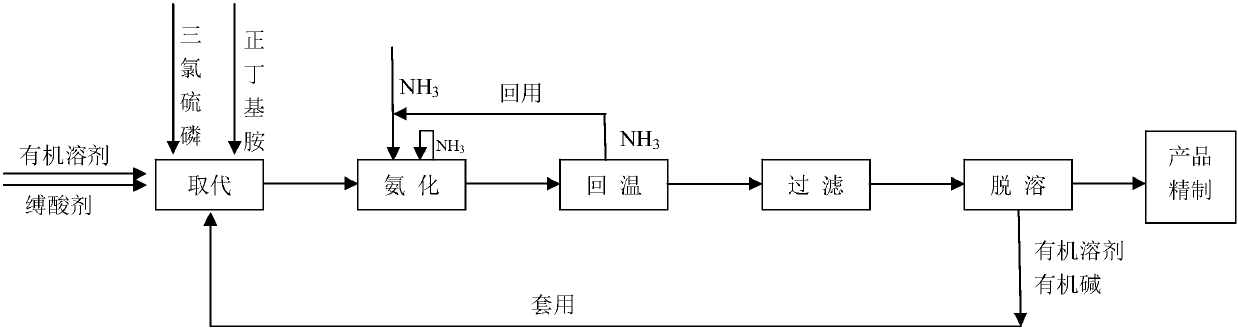

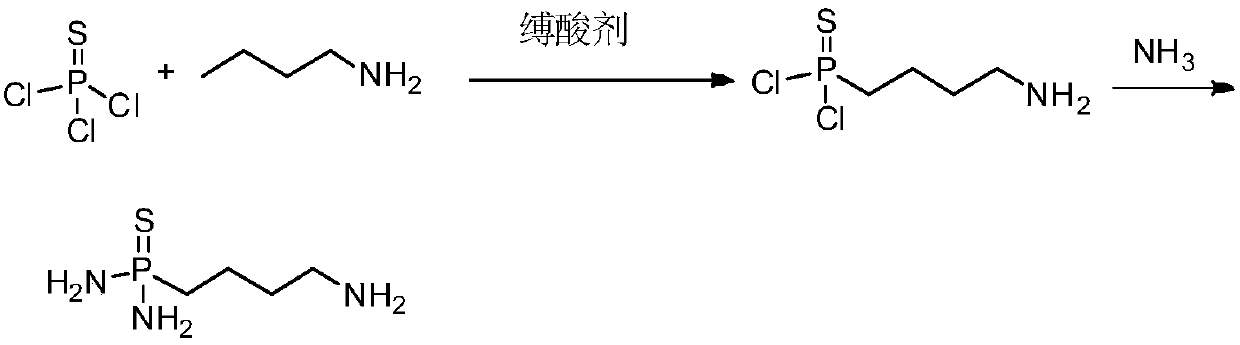

A technology of n-butyl thiophosphoryl triamide and n-butylamino thiophosphoryl dichloride is applied in the field of clean production technology suitable for industrialization, and can solve the problems of low production efficiency, difficult separation, easy formation of agglomeration and the like , to reduce production costs, avoid environmental pollution, and speed up the response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of the composite acid-binding agent is to first put 136.35Kg of triethylamine and 11.85Kg of ammonium bicarbonate into the reaction kettle, start stirring, fully disperse the ammonium bicarbonate in the triethylamine, stir for half an hour, and then pass through the shearing Cut the pump to emulsify and shear the dispersion, fully mix and emulsify the dispersion, and keep it without sedimentation and stratification after standing still.

[0045] Add 250Kg of parathion trichloride dissolved in 1620Kg of ethyl acetate in the reaction kettle and stir, then add the above-mentioned composite acid-binding agent; add 115.4Kg of n-butylamine dropwise into the reaction kettle to carry out the substitution reaction, and control the reaction temperature at - 20°C, keep the dropping time at 2 hours, keep warm for 1 hour after the dropping is completed, take samples and analyze until the content of phosphorus trichloride cannot be detected, end the reaction, and put t...

Embodiment 2

[0049] The preparation of the composite acid-binding agent is to first put 193.05Kg of tripropylamine and 12.60Kg of sodium bicarbonate into the reaction kettle, start stirring, and fully disperse the ammonium bicarbonate into the triethylamine, stir for half an hour, and then pass the shearing The pump emulsifies and shears the dispersion, fully mixes and emulsifies the dispersion, and keeps it without sedimentation and stratification after standing still.

[0050] Add 250Kg of parathion trichloride dissolved in 1550Kg of ethyl acetate in the reaction kettle and stir, then add the above-mentioned composite acid-binding agent; add 115Kg of n-butylamine dropwise into the reaction kettle to carry out the substitution reaction, and control the reaction temperature at -20 ℃, the dropping time is kept at 2 hours, after the dropping is completed, keep warm for 1 hour, take a sample for detection, until the content of phosphorus trichloride cannot be detected, the reaction is ended, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com