A kind of cleaner production method of p-nitroanisole

A technology for p-nitroanisole and cleaner production, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of large amount of by-products, large amount of waste water, and many by-products of hydrolysis, etc. Achieve the effect of improving yield and achieving zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

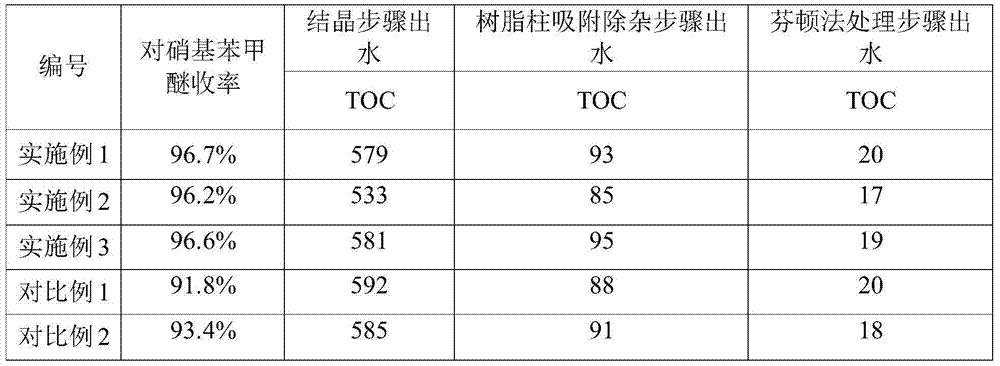

Embodiment 1

[0022] Add 204.4g of p-nitrochlorobenzene and 200g of methanol into a 1000mL autoclave, close the autoclave, slowly raise the temperature until the p-nitrochlorobenzene is basically dissolved, start stirring and continue to heat up to 80°C, and then start to oxidize 460mL of hydrogen Sodium methanol solution (the content of sodium hydroxide is 125g / L) is added in batches to p-nitrochlorinated benzyl alcohol solution for contact reaction, the dropping process is controlled as follows: add 150mL dropwise for about 1 hour; then continue to heat up to 85°C About 230 mL was added dropwise in about 2 hours; then the temperature was raised to 90-95°C, and the remaining sodium hydroxide methanol solution was added dropwise in about 1 hour. Finally, continue to heat up to 100-105° C. for heat preservation reaction, and reach the end of the reaction in about 6 hours.

[0023] Then the obtained reaction product mixture is distilled to obtain gaseous methanol and a distillation substrate,...

Embodiment 2

[0027] Add 204.4g of p-nitrochlorobenzene and 115g of methanol into a 1000mL autoclave, close the autoclave, slowly raise the temperature until the p-nitrochlorobenzene is basically dissolved, start stirring and continue to heat up to 80°C, and then start to oxidize 430mL of hydrogen Sodium methanol solution (the content of sodium hydroxide is 155g / L) is added in batches to p-nitrochlorinated benzyl alcohol solution for contact reaction. The dropping process is controlled as follows: add 150mL dropwise for about 1 hour; then continue to heat up to 85°C Add 200 mL dropwise in about 2 hours; then raise the temperature to 90-95°C, and add the remaining methanolic sodium hydroxide solution dropwise in about 1 hour. Finally, continue to raise the temperature to 100-105° C. and keep it warm for the reaction, and reach the end of the reaction in about 4.5 hours.

[0028] Then the obtained reaction product mixture is distilled to obtain gaseous methanol and distillation bottoms, where...

Embodiment 3

[0032] Add 204.4g of p-nitrochlorobenzene and 150g of methanol into a 1000mL autoclave, close the autoclave, slowly raise the temperature until the p-nitrochlorobenzene is basically dissolved, start stirring and continue to heat up to 80°C, and then start to oxidize 440mL of hydrogen Sodium methanol solution (the content of sodium hydroxide is 140g / L) is added in batches to p-nitrochlorinated benzyl alcohol solution for contact reaction, the dropping process is controlled as follows: add 150mL dropwise for about 1 hour; then continue to heat up to 85°C Add 200 mL dropwise in about 2 hours; then raise the temperature to 90-95°C, and add the remaining methanolic sodium hydroxide solution dropwise in about 1 hour. Finally, continue to heat up to 100-105° C. for heat preservation reaction, and reach the end of the reaction in about 5 hours.

[0033] Then the obtained reaction product mixture is distilled to obtain gaseous methanol and distillation bottoms, wherein, the gaseous met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com