A system and method for producing compound fertilizer using chemical tail gas

A technology for chemical exhaust gas and compound fertilizer, applied in nitrogen fertilizer, application, fertilization device and other directions, can solve the problems of unsuitable compound fertilizer, many rotating equipment, overcapacity of urea, etc., to improve energy utilization rate, strong market competitiveness, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

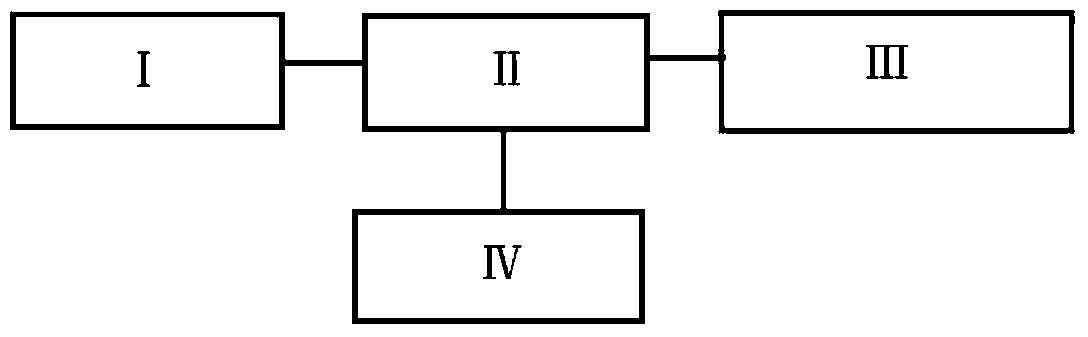

[0055] Such as figure 1 As shown, a system for producing compound fertilizer using chemical tail gas, including sequentially connected ammonia evaporation unit I, ammonium nitrate solution preparation unit II, nitro compound fertilizer preparation unit III, nitro compound fertilizer preparation unit III and neutralization washing unit IV connection;

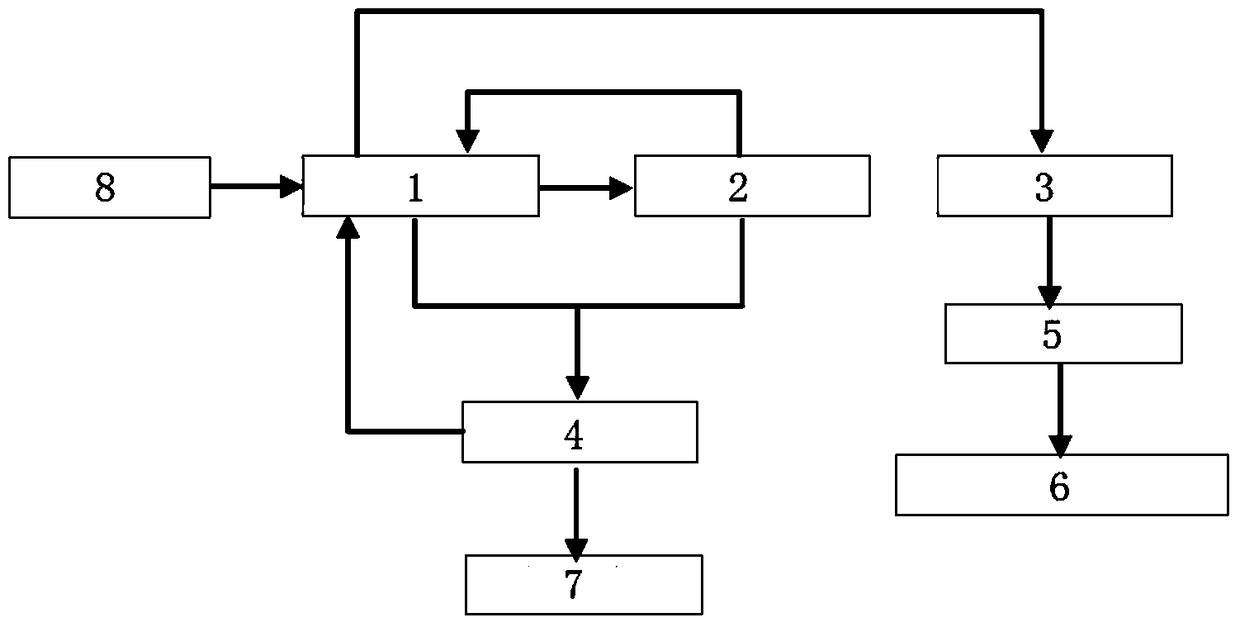

[0056] Such as figure 2 As shown, the ammonia evaporation unit I mainly includes a liquid ammonia buffer tank 1, a gas ammonia filter 3 and a gas ammonia superheater 5 connected in sequence; the inlet of the liquid ammonia buffer tank 1 is connected to the liquid ammonia spherical tank 8, and the inlet of the liquid ammonia buffer tank 1 Connect liquid ammonia evaporator 2, the outlet of liquid ammonia buffer tank 1 and liquid ammonia evaporator 2 is connected to blowdown evaporator 4, the outlet of blowdown evaporator 4 is respectively connected to liquid ammonia buffer tank 1 and blowdown tank 7, and gas ammonia superheater 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com