A method for making superconducting joints for rare earth barium copper oxide high temperature superconducting wires

A technology of rare earth barium copper oxide and superconducting joints, which is applied in the direction of superconducting/high-conducting conductors, the usage of superconducting elements, conductive connections, etc., can solve the problems of unfavorable industrial production, long time-consuming, high cost, etc., and achieve shortened production time, The effect of reducing production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

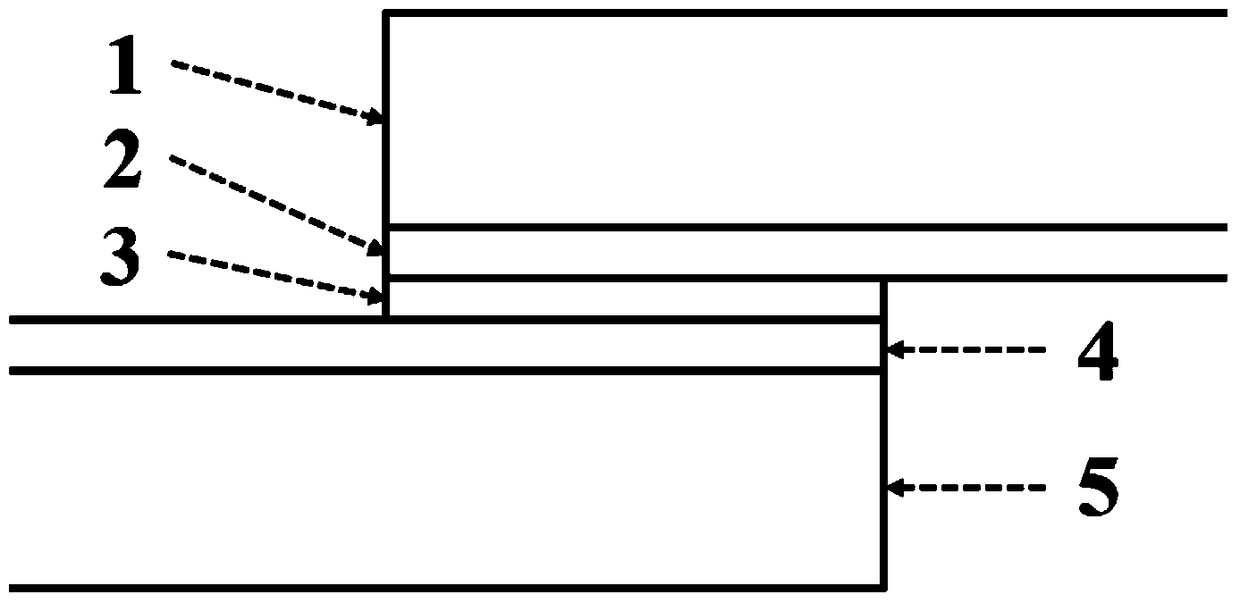

[0045] A method for manufacturing a superconducting joint for a rare earth barium copper oxide high temperature superconducting wire, comprising the following steps:

[0046] (S1) corroding the silver stabilizing layers at the ends of the two superconducting wires to expose the superconducting layers;

[0047] (S2) mixing rare earth barium copper oxide powder and silver powder as auxiliary agent, as powder solder;

[0048] (S3) placing the superconducting layers of the two wires facing each other, and adding powdered solder in the middle;

[0049] (S4) pressurize and fix the two wires with powdered solder added in the middle;

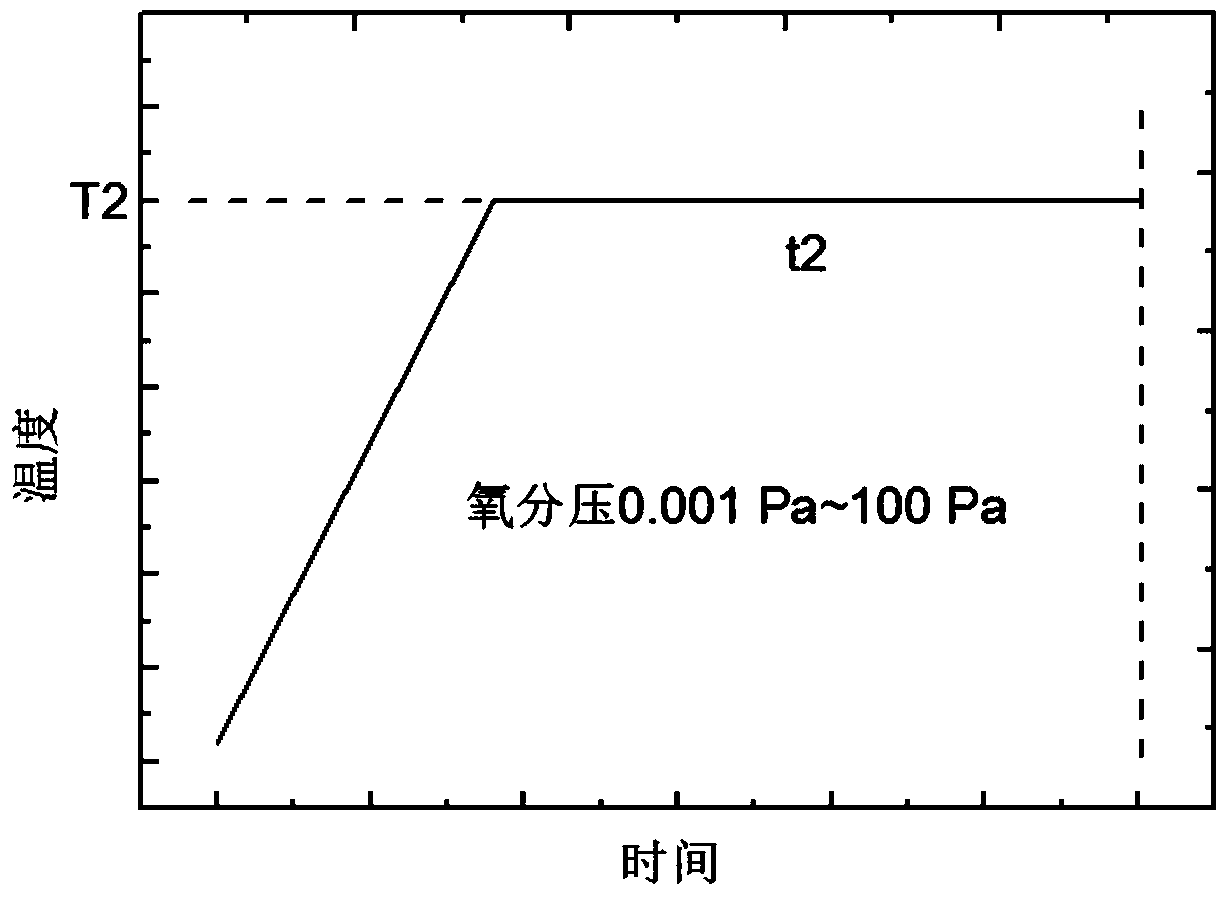

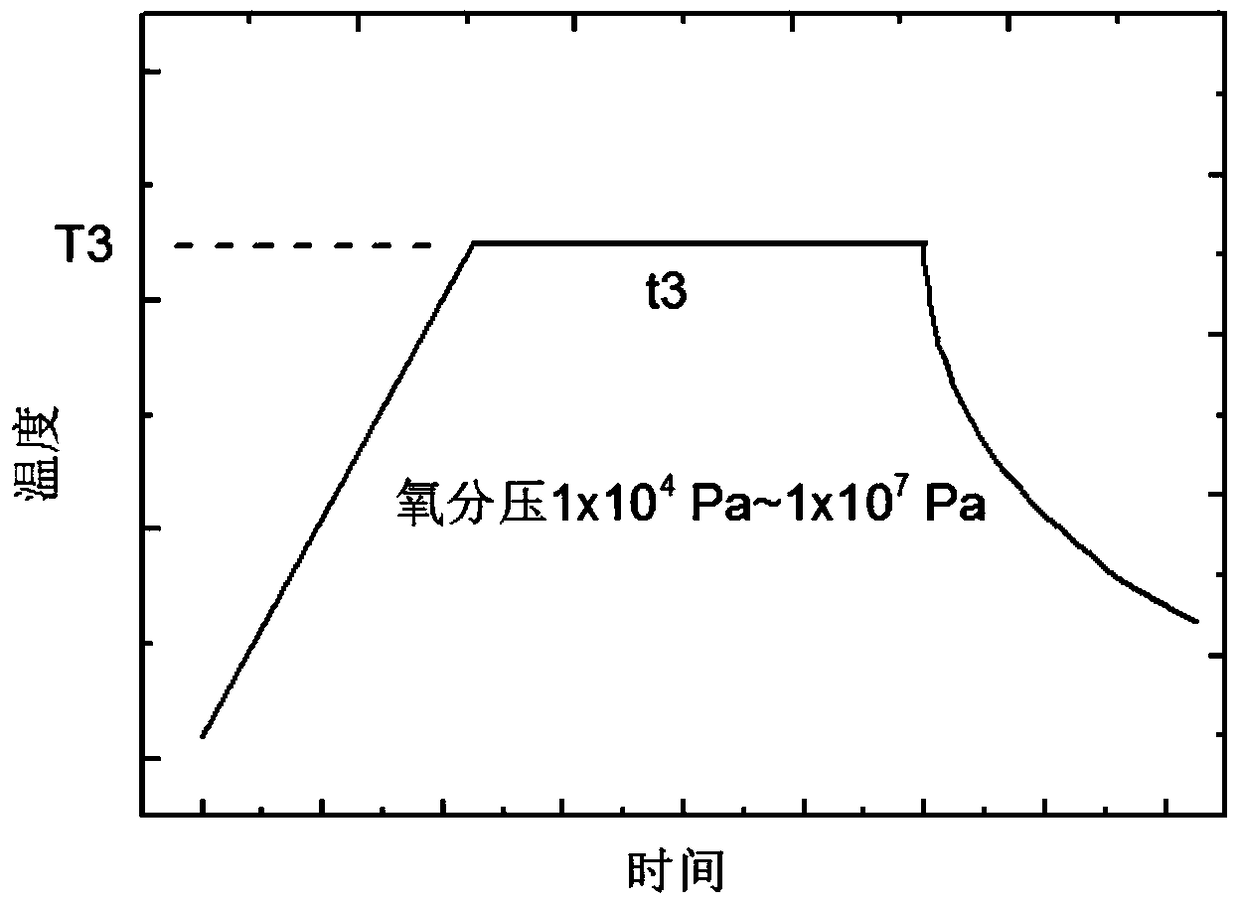

[0050] (S5) performing heat treatment under low oxygen partial pressure to locally melt the powdered solder, and then generate a rare-earth barium-copper-oxygen phase in an oxygen-deficient state, and the phase grows epitaxially on the surface of the superconducting layer to connect the two superconducting layers;

[0051] (S6) Oxygenation heat treatm...

Embodiment 2

[0061] A method for manufacturing a superconducting joint for a rare earth barium copper oxide high temperature superconducting wire, comprising the following steps:

[0062] (S1) corroding the silver stable layers at the ends of the two superconducting wires to expose the superconducting layers;

[0063] (S2) mixing yttrium oxide powder, barium carbonate (or barium oxide) powder, copper oxide powder and KOH powder as auxiliary agent to obtain powder solder;

[0064] (S3) placing the superconducting layers of the two wires facing each other, and adding powdered solder in the middle;

[0065] (S4) pressurize and fix the two wires with powdered solder added in the middle;

[0066] (S5) performing heat treatment under low oxygen partial pressure to cause the powder solder to react, and the oxygen-deficient rare earth barium copper oxide phase grows epitaxially on the surface of the superconducting layer to connect the two superconducting layers;

[0067] (S6) Oxygenation heat t...

Embodiment 3

[0072] An epitaxial growth joint technology applied to the welding of two rare-earth barium-copper-oxygen high-temperature superconducting wires in a non-parallel position relationship. The operation steps of this embodiment are basically the same as those of Embodiment 1, only in step S2, according to the needs of coil winding , while placing the two wires face to face, using a certain angle θ, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com