Water-based white polyester coil coating special for aluminum ceiling finish paint and preparation method of water-based white polyester coil coating

A technology of coil coating and modified polyester, applied in polyester coating, epoxy resin coating, coating, etc., can solve the problems of poor flexibility of water-based coil coating, achieve flexibility, environmental protection, easy implementation, and reduce Effect of VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Example 1: A water -based white polyester coating for an aluminum ceiling paint for each component and quality percentage of each component and quality of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings of the coatings and quality of the quality of the coatings.

[0073] Remove water: 11.02%

[0074] Solvent: 1.69%

[0075] Different agent: 1.69%

[0076] Catalyst: 0.42%

[0077] Amino tree refers to: 5.5%

[0078] Candid agent: 1.69%

[0079] Fubbie: 0.42%

[0080] Flowing agent: 0.42%

[0081] Titanium white powder: 28%

[0082] Water -based polyester modified epoxy: 6.78%

[0083] Water -based organic silicon modified polyester resin is 40.68%.

[0084] Regulating agent: 1.69%

[0085] The following is the following detailed explanation method:

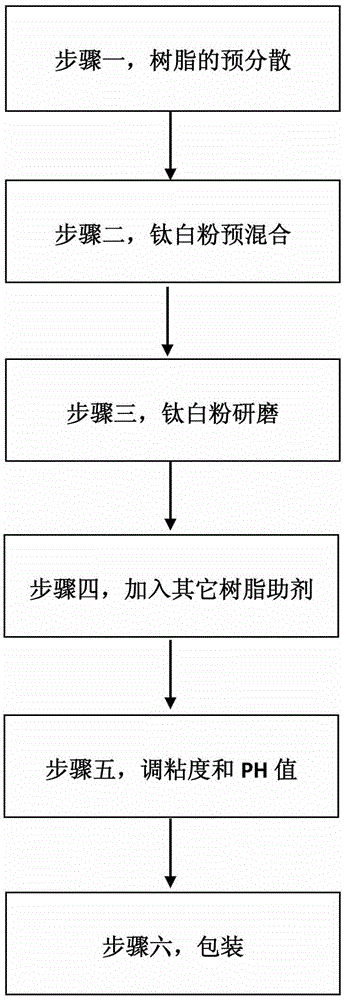

[0086] like figure 1 Show: The preparation method of water -based white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com