Wire-filled electron beam welding method for titanium metal material and aluminum alloy material

A technology of electron beam welding and aluminum alloy materials, which is applied in the field of wire-filled electron beam welding of titanium metal materials and aluminum alloy materials, can solve the problems of large differences in physical properties, poor mechanical properties of welds, and metallurgical incompatibility, etc. Achieve the effects of improving mechanical properties, improving forming, and avoiding welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Select TA15 titanium alloy test plate base material and aluminum alloy test plate base material to carry out electron beam welding, welding steps are:

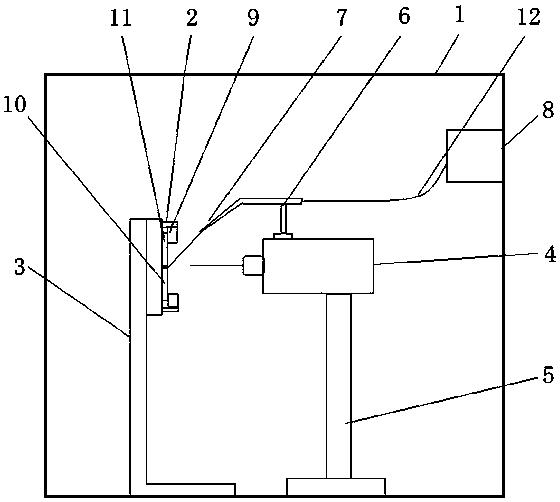

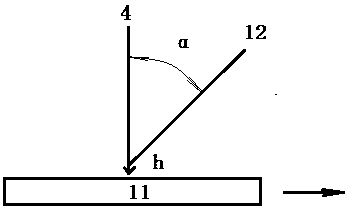

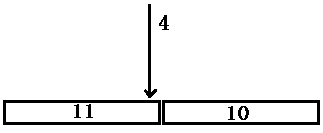

[0024] 1. Choose vacuum device first, the vacuum device used in the present invention comprises vacuum chamber 1, is provided with fixture 2, fixture mobile support 3, servo motor, electron beam welding torch 4, welding torch mobile support 5, nozzle support in described vacuum chamber 1 6. The wire feeding nozzle 7 and the wire feeding mechanism 8, the fixture moving bracket 3 and the welding torch moving bracket 5 are arranged in parallel, the upper end of the fixture moving bracket 3 is fixedly connected with the fixture 2, and the lower end of the fixture moving bracket 3 passes through a horizontal slide rail Slidingly connected with the vacuum chamber 1 and driven by a horizontal servo motor, the fixture is provided with a fixture buckle 9, the upper end of the welding torch moving bracket 5 is fixedl...

Embodiment 2

[0028] 1. Choose vacuum device first, the vacuum device used in the present invention comprises vacuum chamber 1, is provided with fixture 2, fixture mobile support 3, servo motor, electron beam welding torch 4, welding torch mobile support 5, nozzle support in described vacuum chamber 1 6. The wire feeding nozzle 7 and the wire feeding mechanism 8, the fixture moving bracket 3 and the welding torch moving bracket 5 are arranged in parallel, the upper end of the fixture moving bracket 3 is fixedly connected with the fixture 2, and the lower end of the fixture moving bracket 3 passes through a horizontal slide rail Slidingly connected with the vacuum chamber 1 and driven by a horizontal servo motor, the fixture is provided with a fixture buckle 9, the upper end of the welding torch moving bracket 5 is fixedly connected with the electron beam welding torch 4, and the lower end slides with the vacuum chamber 1 through a longitudinal slide rail connected, and driven by a longitudin...

Embodiment 3

[0032] 1. Choose vacuum device first, the vacuum device used in the present invention comprises vacuum chamber 1, is provided with fixture 2, fixture mobile support 3, servo motor, electron beam welding torch 4, welding torch mobile support 5, nozzle support in described vacuum chamber 1 6. The wire feeding nozzle 7 and the wire feeding mechanism 8, the fixture moving bracket 3 and the welding torch moving bracket 5 are arranged in parallel, the upper end of the fixture moving bracket 3 is fixedly connected with the fixture 2, and the lower end of the fixture moving bracket 3 passes through a horizontal slide rail Slidingly connected with the vacuum chamber 1 and driven by a horizontal servo motor, the fixture is provided with a fixture buckle 9, the upper end of the welding torch moving bracket 5 is fixedly connected with the electron beam welding torch 4, and the lower end slides with the vacuum chamber 1 through a longitudinal slide rail connected, and driven by a longitudin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com