High-coercivity samarium-cobalt permanent magnet material and preparation method thereof

A technology of permanent magnet materials and high coercive force, applied in the direction of magnetic materials, magnetic objects, electrical components, etc. The effect of domain magnetocrystalline anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

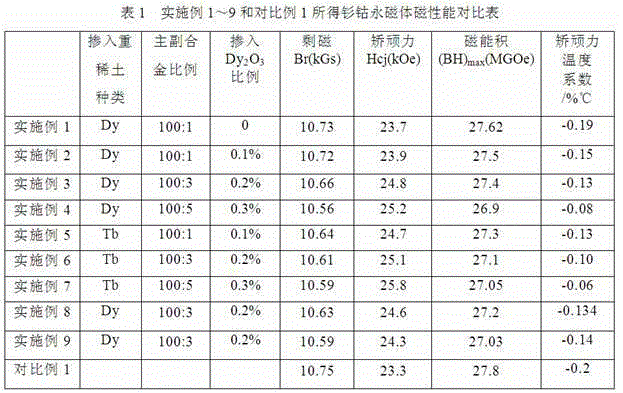

Examples

Embodiment 1

[0032] The high coercive force samarium cobalt permanent magnet material of the present embodiment comprises main alloy and auxiliary alloy, and the mass ratio of main alloy and auxiliary alloy is 100:1; The chemical formula of main alloy is Sm 24.5% co 49.5% Fe 16.2% Cu 6.1% Zr 3.7% , the suballoy according to the chemical formula is Sm 20% Dy 60% Fe 20% .

[0033] The preparation method of the high-coercivity samarium-cobalt permanent magnet material in this embodiment is to prepare the samarium-cobalt permanent magnet through the double alloy method combined with the traditional powder metallurgy process, and prepare the main alloy and the auxiliary alloy, which specifically includes the following steps:

[0034] Steps (1), (2), and (3) are the preparation of the main alloy powder:

[0035] (1) Ingredients: main alloy according to chemical formula Sm 24.5% co 49.5% Fe 16.2% Cu 6.1% Zr 3.7% The mass percentage ingredients;

[0036] (2) Melting: Put the main allo...

Embodiment 2

[0047] The high coercive force samarium cobalt permanent magnet material of the present embodiment comprises main alloy and auxiliary alloy, and the mass ratio of main alloy and auxiliary alloy is 100:1; The chemical formula of main alloy is Sm 24.5% co 49.5% Fe 16.2% Cu 6.1% Zr 3.7% , the suballoy according to the chemical formula is Sm 20% Dy 60% Fe 20% .

[0048] The preparation method of the high-coercivity samarium-cobalt permanent magnet material in this embodiment is to prepare the samarium-cobalt permanent magnet through the double alloy method combined with the traditional powder metallurgy process, and prepare the main alloy and the auxiliary alloy, which specifically includes the following steps:

[0049] Steps (1), (2), and (3) are the preparation of the main alloy powder:

[0050] (1) Ingredients: main alloy according to chemical formula Sm 24.5% co 49.5% Fe 16.2% Cu 6.1% Zr 3.7% The mass percentage ingredients;

[0051] (2) Put the main alloy raw mat...

Embodiment 3

[0062] The high-coercivity samarium-cobalt permanent magnet material of the present embodiment comprises a main alloy and a secondary alloy, and the mass ratio of the main alloy and the secondary alloy is 100:3; the chemical formula of the main alloy is Sm 24.5% co 49.5% Fe 16.2% Cu 6.1% Zr 3.7% , the suballoy according to the chemical formula is Sm 20% Dy 60% Fe 20% .

[0063] The preparation method of the high-coercivity samarium-cobalt permanent magnet material in this embodiment is to prepare the samarium-cobalt permanent magnet through the double alloy method combined with the traditional powder metallurgy process, and prepare the main alloy and the auxiliary alloy, which specifically includes the following steps:

[0064] Steps (1), (2), and (3) are the preparation of the main alloy powder:

[0065] (1) The main alloy is according to the chemical formula Sm 24.5% co 49.5% Fe 16.2% Cu 6.1% Zr 3.7% The mass percentage ingredients;

[0066] (2) Put the main all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com