Optical fiber panel and its preparation method

A technology of optical fiber panels and optical fibers, applied in the direction of bundled optical fibers, etc., can solve problems such as poor anti-devitrification performance, poor stability, and demanding molding atmosphere environment, and achieve the effect of reasonable theoretical basis and feasible operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the optical fiber panel that this embodiment proposes, comprises:

[0032] In step 1, borosilicate glass is selected as skin glass, and boron-lanthanum-barium glass is selected as core glass to make a glass rod-tube composite. The inner diameter of the glass rod and tube composite is (25±0.5) mm, the wall thickness is (4.0±0.1) mm; the outer diameter of the rod is (25±0.5) mm, and the fit gap is ≤0.5 mm.

[0033] In step 2, the glass rod and tube complex is made into an acid-soluble blank through wire drawing, typesetting, hot pressing, slicing and polishing.

[0034] The drawing is done three times, and the drawing temperature is 850°C; for the first drawing, the glass rod-tube composite is made into a monofilament, and the diameter of the monofilament is (2.5±0.002) mm; Secondary wire drawing, the monofilament is bound to make a regular hexagonal primary multifilament rod, the opposite side of the multifilament rod is 20mm, and the primary m...

Embodiment 2

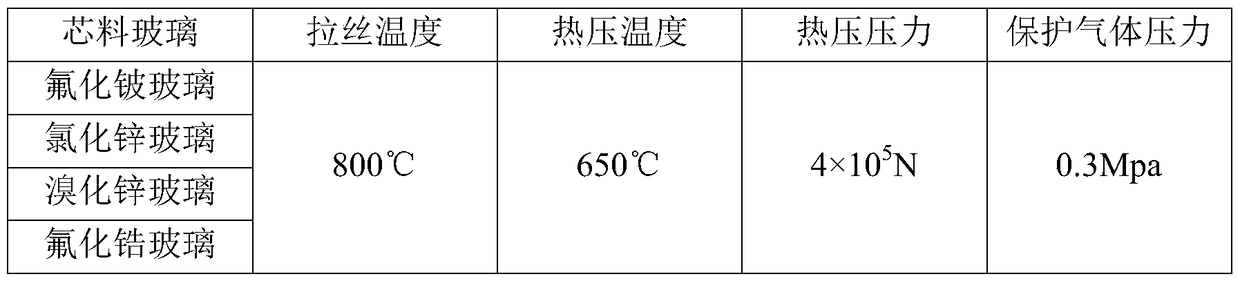

[0047] The differences between the preparation method of the optical fiber panel proposed in this embodiment and that of Embodiment 1 are shown in Table 1, and other preparation steps are basically the same as those of Embodiment 1.

[0048] Table 1 Main preparation parameters of fiber optic panels

[0049]

[0050] Using the above preparation method, an optical fiber panel using halide glass such as beryllium fluoride glass, zinc chloride glass, zinc bromide glass or zirconium fluoride glass as the core material glass was prepared. The performance test of the optical fiber panel prepared in this embodiment The result is as follows:

[0051] The performance test results of the fiber optic panel are as follows:

[0052] 1. Spectral transmission range:

[0053] The spectral transmittance range of the optical fiber panel is 2500-7000nm, the total transmittance is greater than 40%, and the light transmittance difference at any two wavelengths is less than 20%.

[0054] 2. Knif...

Embodiment 3

[0057] The differences between the preparation method of the optical fiber panel proposed in this embodiment and that of Embodiment 1 are shown in Table 2, and other preparation steps are basically the same as those of Embodiment 1.

[0058] Table 2 Main preparation parameters of fiber optic panels

[0059] Core Glass

Drawing temperature

Hot pressing temperature

Shielding gas pressure

900℃

710℃

5×10 5 N

1Mpa

[0060] Using the above preparation method, an optical fiber panel with calcium aluminate glass as the core material glass was produced. The performance test results of the optical fiber panel prepared in this embodiment are as follows:

[0061] The performance test results of the fiber optic panel are as follows:

[0062] 1. Spectral transmission range:

[0063] The spectral transmittance range of the optical fiber panel is 2500-7000nm, the total transmittance is greater than 40%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com