The mechanical model modeling method and its application based on the temperature rise rate of the mold under the production condition of continuous plastic processing

A technology of plastic processing and production conditions, applied in the field of metal plastic forming process analysis, can solve the problem of inability to accurately analyze the temperature rise of the mold, and achieve the effect of saving calculation time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

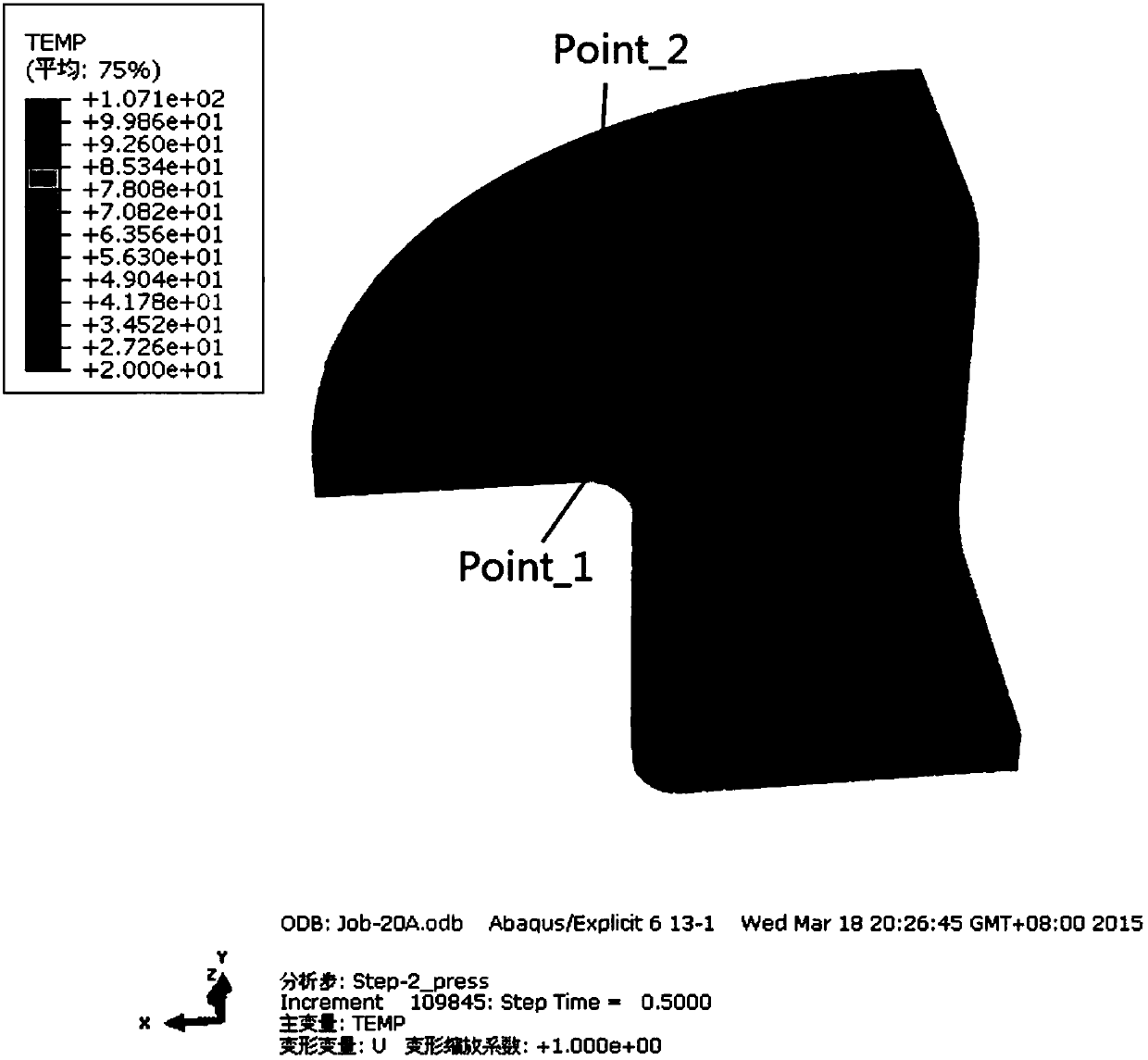

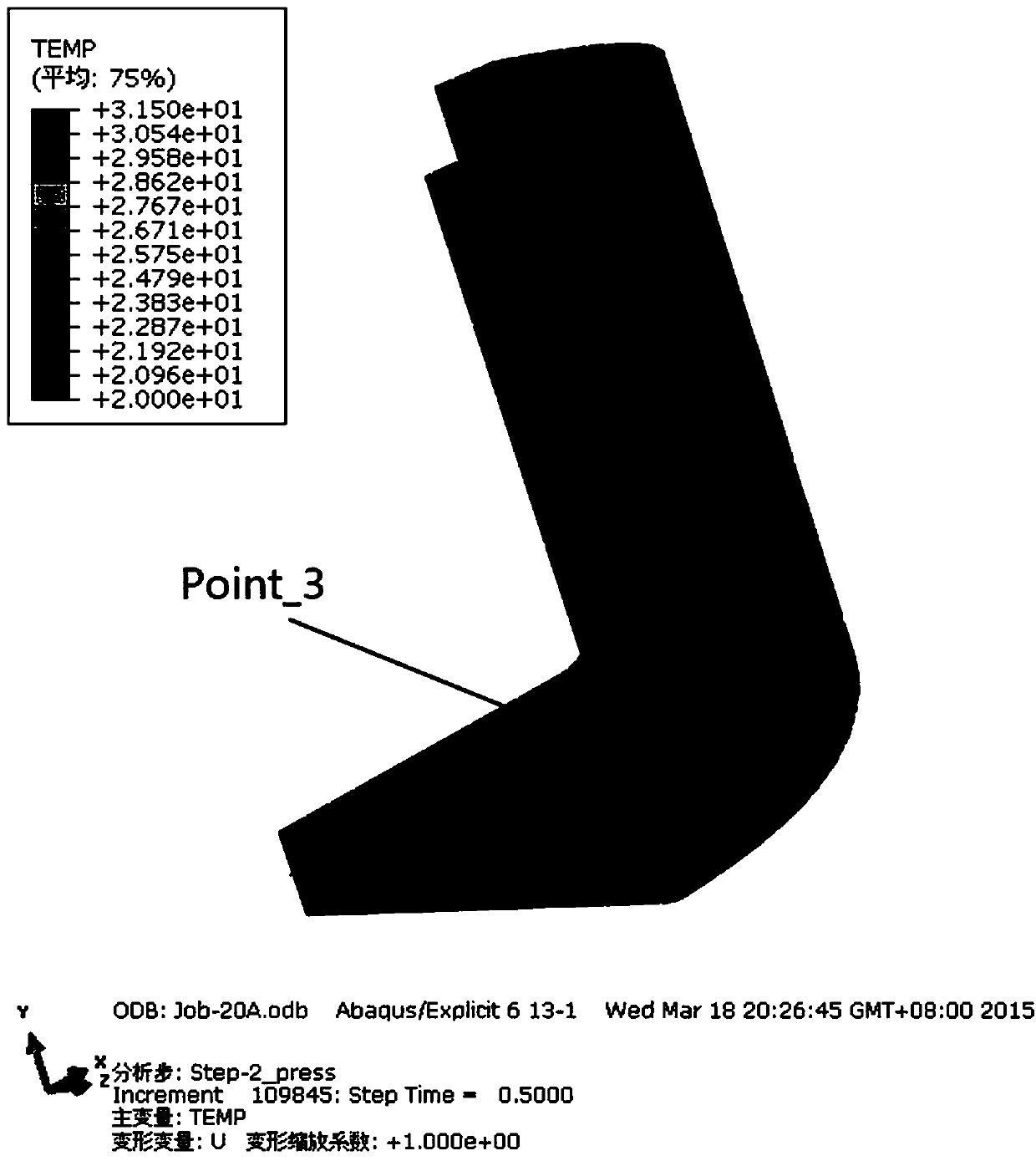

[0037] Such as Figure 5 Shown is the flow chart of the modeling method in the present invention. In order to describe the technical solution of the present invention more clearly, the technical solution of the present invention will be further explained and illustrated in the form of specific embodiments in conjunction with the accompanying drawings.

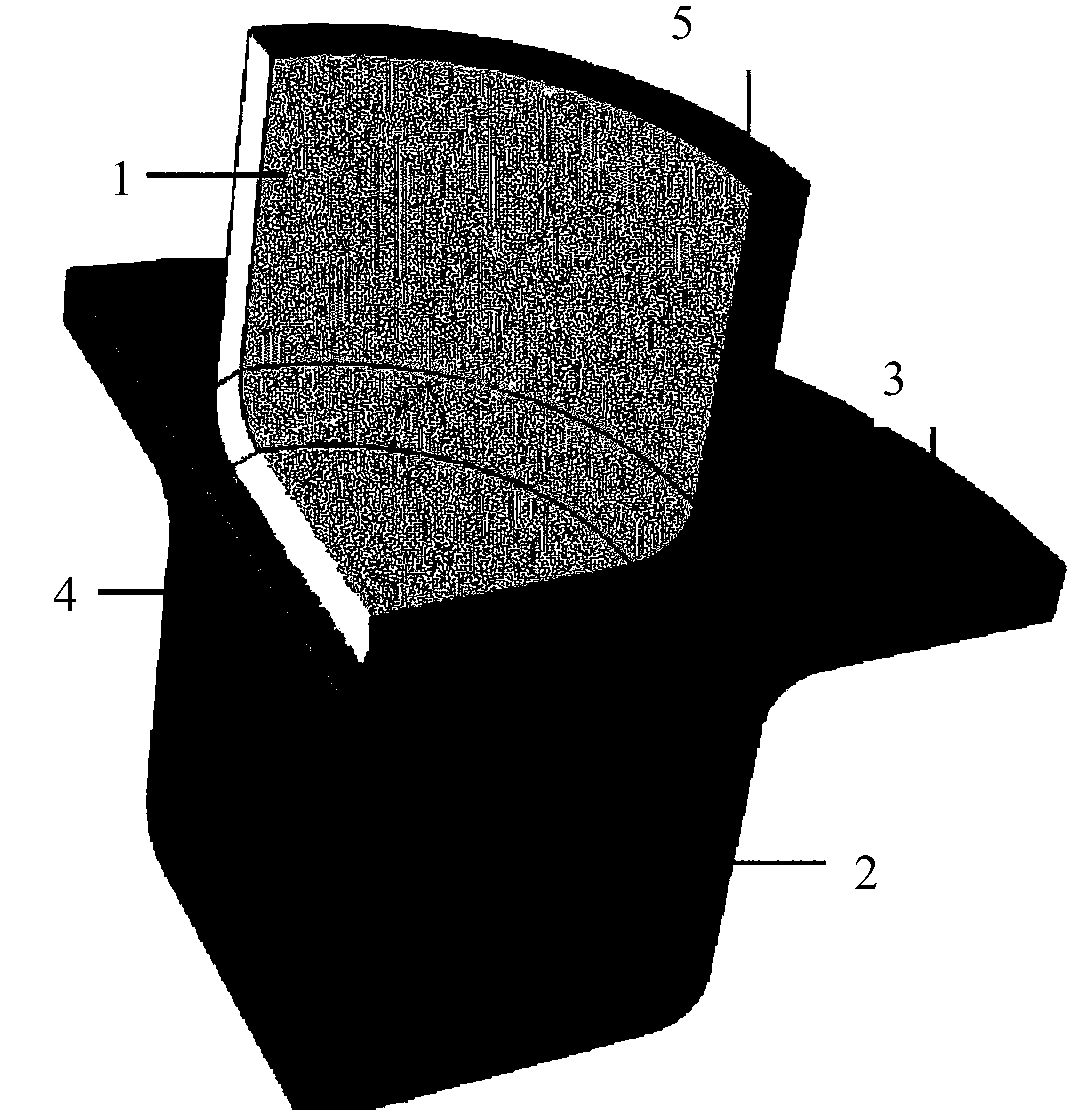

[0038] 1. Example model establishment

[0039] The present invention takes the virtual model of the normal-temperature deep drawing of the cylindrical part as an example, and the main purpose is to explain how to apply the analysis method provided by the present invention to solve the temperature rise problem of the continuous deep drawing of the cylindrical part. In order to make the analyzed problems more pertinent, the formability problems such as cracking and wrinkling in sheet deep drawing and material wear and fatigue in continuous stamping are not considered. At the same time, in order to highlight the generality of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com