Method and device for testing thermal property of semicokes generated by cracking of block coal

A test method and thermal performance technology, applied in the thermal performance test method and test device field of semi-coke generated after lump coal cracking, can solve the problems of unknown reaction process, low strength, inaccurate semi-coke evaluation, etc., and achieve simple structure, Easy to operate, accurate evaluation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

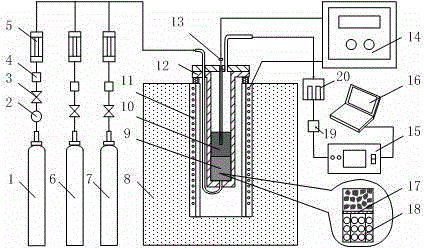

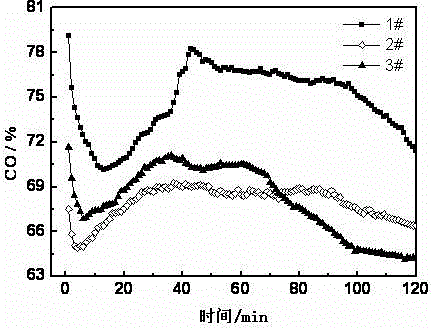

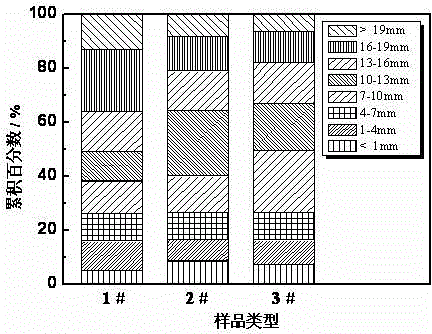

[0036] Example: see Figure 1~3 , a method for testing the thermal properties of semi-coke generated after lump coal cracking. It is tested on 3 kinds of coal samples (1#, 2#, 3#). The 3 kinds of coal are all non-coking lump coal used by COREX.

[0037] The thermal performance test method of generating semi-coke after specific lump coal pyrolysis comprises the following steps:

[0038] Step 1: Screen 2~3kg of 1#, 2#, 3# dry lump coal with a particle size of 25~30mm, package it in a coking tank and quickly (when the coking tank is put into the furnace, the speed should be as fast as possible, put it into the furnace for high-temperature pyrolysis) placed in a coke oven at a temperature of 1000-1100°C for 0.5-2h; the temperature of the coke oven is suitably controlled at 1000°C, and the residence time is 1h. After taking it out, it is cooled to room temperature to obtain the initial semi-coke, which is used as a preferred test of this embodiment. Sample;

[0039] Step 2: Car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com