Micro semi-ring female die array-mode lapping and polishing method and device

A semi-ring concave die and array technology, which is applied in the direction of grinding device, grinding machine tool, grinding tool, etc., to achieve the effect of low surface roughness, high efficiency and high shape consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

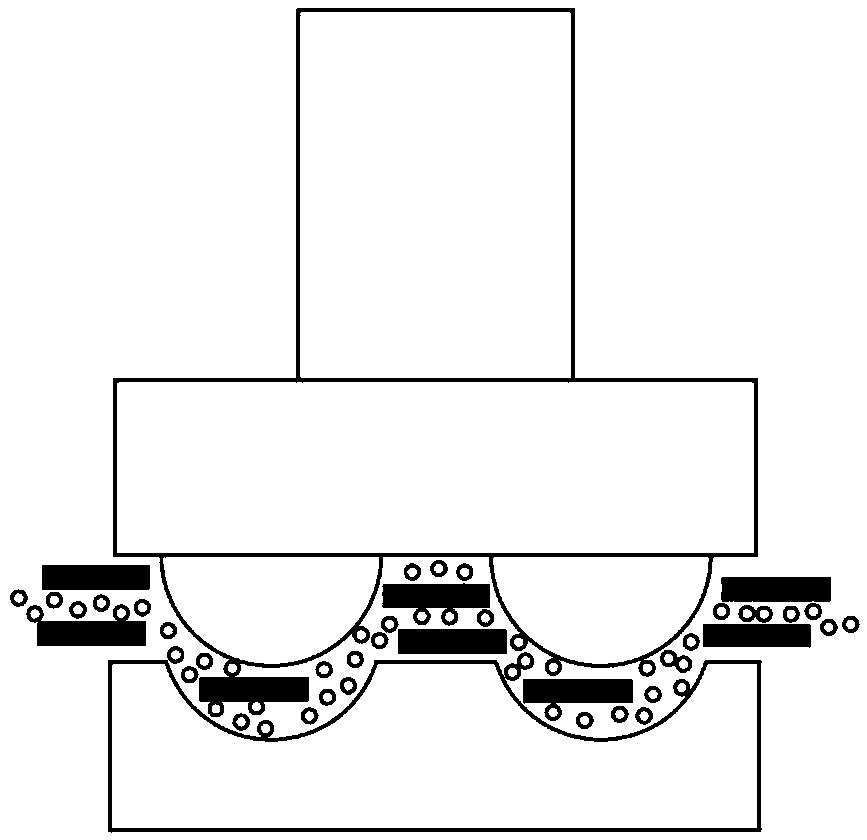

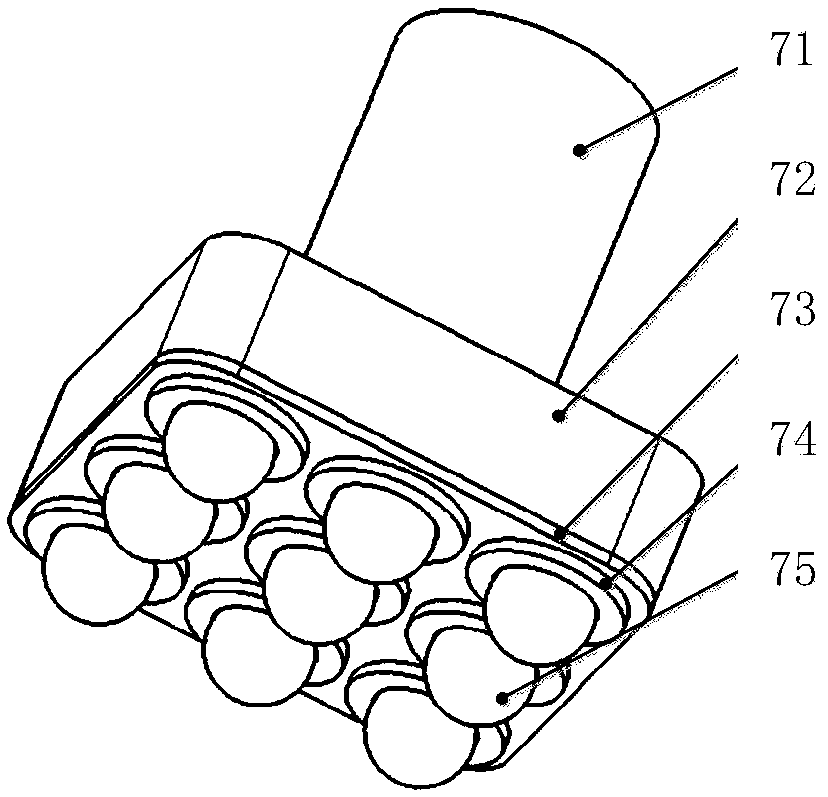

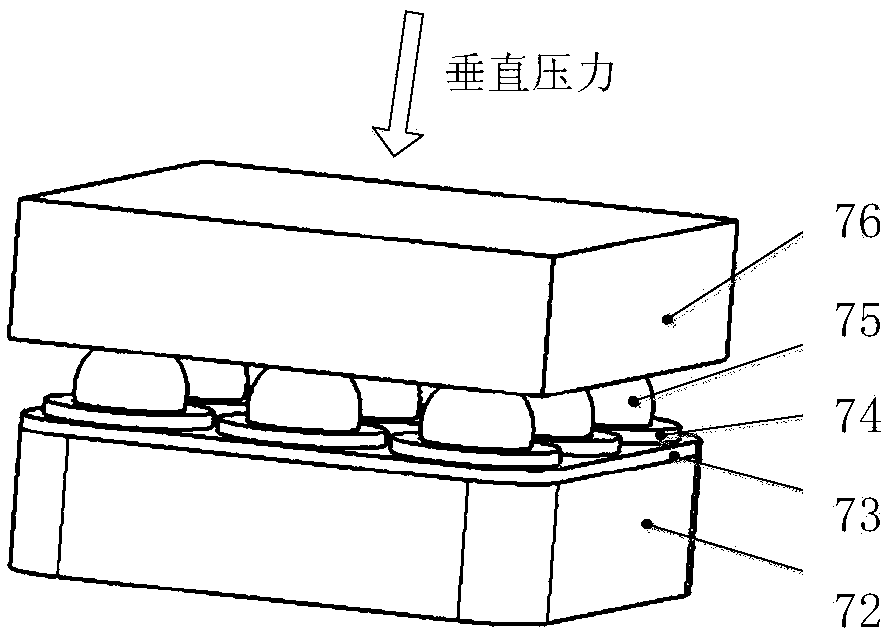

[0028] refer to Figure 1 to Figure 5 , a micro-semi-ring die array polishing method, the polishing method comprises the following steps:

[0029] 1) Making ultra-precision and high-consistency grinding and polishing molds

[0030] Described polishing mold comprises tool connecting rod 71, positioning base plate 72, precision sphere 75, and the upper end of tool connecting rod 71 is connected with fine ultrasonic generator, and the lower end of described tool connecting rod 71 is connected with positioning base plate 72, on positioning base plate An array of apertures is processed on 72, the aperture size is smaller than the diameter of the precision sphere, and the gap between the aperture and the precision sphere 75 is filled with adhesive, and a part of the sphere is embedded in the hole;

[0031] 2) The gap between the ultra-precision and high-consistency polishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com