Method for improving flavor and stability of shellfish protein enzymatic hydrolyzate

A protein enzymatic hydrolysis solution and stability technology, applied in the field of aquatic product processing, can solve the problems of changing the original characteristic flavor, unfavorable large-scale production, large loss of amino acids, etc., and achieve the effects of large-scale production, simple method and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the processing of pearl oyster meat

[0035] 1. Chitosan coagulation treatment

[0036] Take 500 grams (crude protein content 14.5%) of Martensii pearl oyster meat that has been stirred evenly by a beater, add deionized water according to the mass ratio of Martensii pearl oyster meat to deionized water as 1:1, and control the temperature at 55°C after mixing. ℃, add trypsin and alkaline protease according to the weight of shellfish meat at 1.5‰ (the weight ratio of trypsin and alkaline protease is 1:1), control the temperature for enzymolysis for 5 hours, then raise the temperature to 121°C to inactivate the enzyme for 15 minutes, After the enzymolysis reaction solution is filtered through a plate frame, the enzymatic hydrolysis solution of pearl oyster meat protein is obtained. Get 500mL of the above-mentioned prepared pearl oyster oyster meat protein enzymatic hydrolyzate, add 1mL mass fraction 1% chitosan acetic acid solution (1 gram deacetylation degr...

Embodiment 2

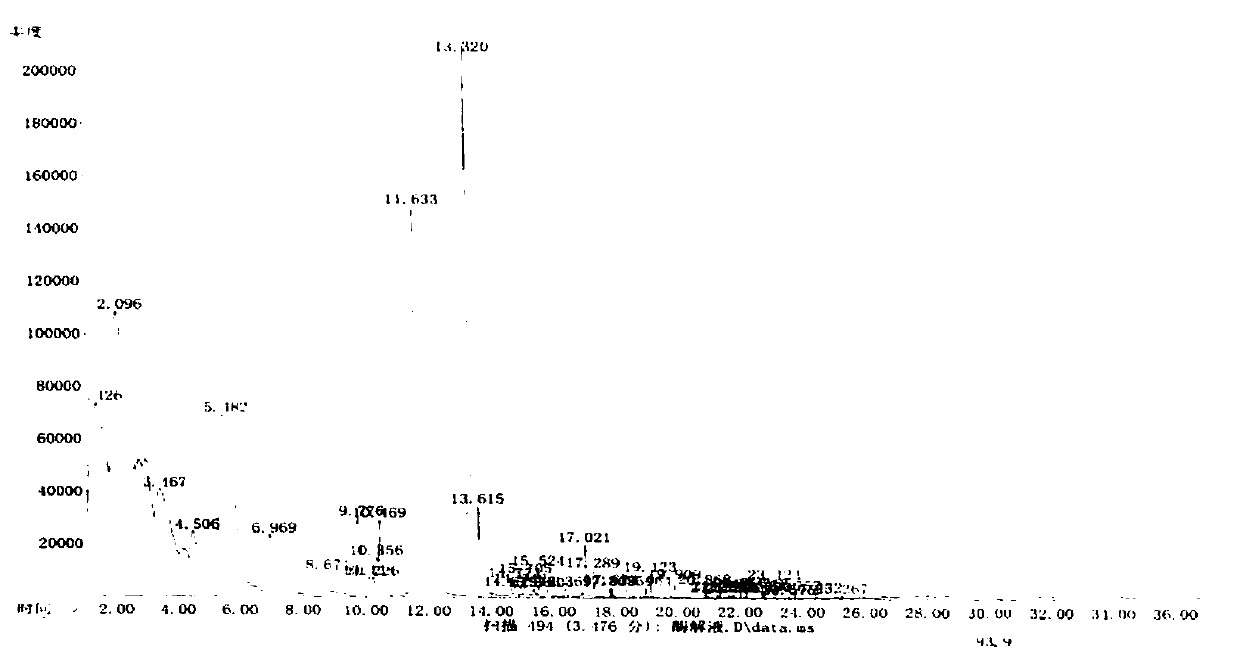

[0039] Example 2: GC-MS analysis of the enzymatic hydrolysis stock solution and flocculated macromolecular substances of Pearl Oyster oyster meat

[0040] Take 5 grams of the flocculation material prepared in step 1 in Example 1, add 5 mL of deionized water, mix well, transfer to a 15 mL sample bottle, quickly add 0.8 mL of 4% sodium dodecylsulfonate by mass fraction, and quickly After sealing and mixing, after equilibrating at room temperature for 5 minutes, depolymerize to obtain a flocculated macromolecular substance solution, insert the SPME fiber headspace extraction for 40 minutes, and insert the SPME column into the GC inlet at 260 °C for 5 minutes for analysis. In addition, take 10mL of the pearl oyster meat protein enzymatic hydrolyzate (without chitosan treatment) prepared in step 1 in Example 1, transfer to a 15mL sample bottle, insert the SPME fiber headspace extraction for 40min, insert the SPME column The GC inlet at 260°C was analyzed for 5 minutes for comparati...

Embodiment 3

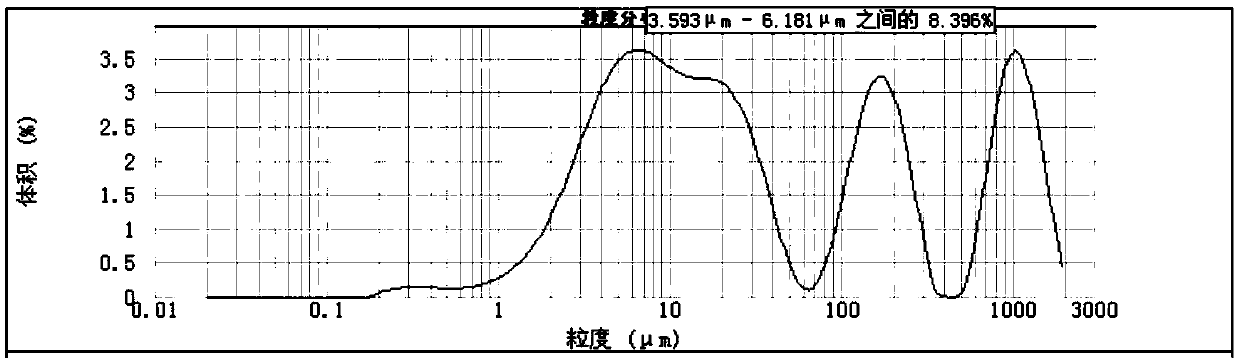

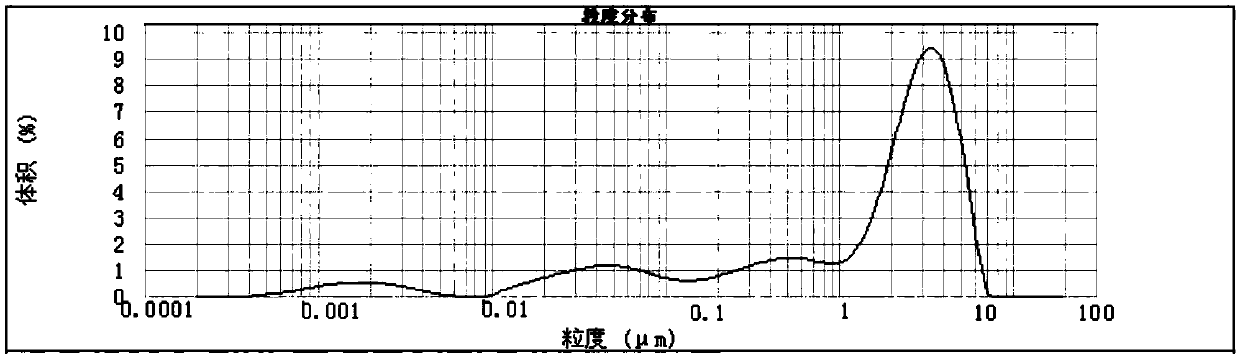

[0045] Example 3: Comparison of the particle size distribution of pearl oyster meat protein enzymatic hydrolyzate and the enzymatic hydrolyzate of pearl oyster martensii meat with improved flavor and stability after chitosan coagulation treatment

[0046] Get the pearl oyster oyster meat protein enzymatic hydrolyzate of step 1 in embodiment 1 (without chitosan treatment) and each 500mL of the pearl oyster owl meat protein enzymatic hydrolyzate that has improved local flavor and stability after chitosan coagulation treatment , placed in a particle size analyzer for laser particle size analysis. The particle size analysis conditions are as follows: laser particle size analyzer: Mastersizer2000, Malvern InstrumentsLTD, UK; sampler name: Hydro2000MU(A); analysis mode: general; particle refractive index: 1.52; particle absorption rate: 0.1; dispersant name: deionized ultrapure Water; dispersant refractive index: 1.33; pump speed: 2200r / min.

[0047] The results of laser particle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com