Inverted organic electroluminescent device and preparation method thereof

An electroluminescent device, an inverted technology, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of unconsidered optical performance of devices and the influence of optical performance of inverted devices, and achieves good optical effects. , The effect of good electron injection ability and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] SiO 2 : silicon dioxide;

[0030] TiO 2 :Titanium dioxide

[0031] NPB: (N,N'-diphenyl-N,N'-(1-naphthyl)-1,1'-biphenyl-4,4'-diamine);

[0032] C545T: 2,3,6,7-tetrahydro-1,1,7,7-tetramethyl-1H,5H,11H-10-(2-benzothiazolyl)-quinazino[9,9A, 1GH] coumarin;

[0033] MADN: 2-methyl-9,10-bis(naphthalen-2-yl)anthracene

[0034] Alq 3 : aluminum octahydroxyquinoline;

[0035] Al: aluminum.

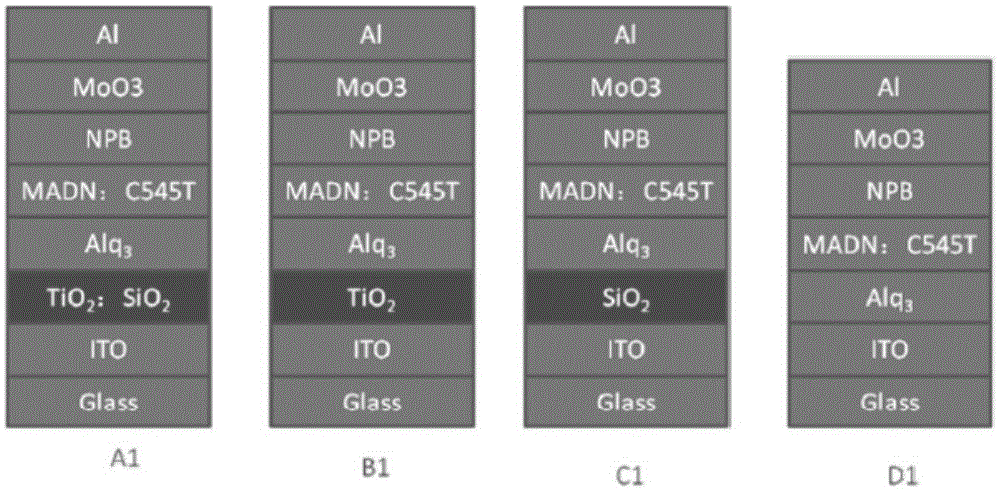

[0036] The structure of the prepared device A1 is: Glass (substrate) / ITO (cathode layer) / TiO 2 : SiO 2 (electron injection layer) / Alq 3 (electron transport layer) / MADN: C545T (green fluorescent light-emitting layer) / NPB (hole transport layer) / MoO3( hole injection layer) / Al (anode layer).

[0037] The optical refractive index of the electron injection layer is 1.78.

[0038] The preparation method is as follows:

[0039] After selecting the glass substrate, prepare the ITO cathode layer, TiO 2 : SiO 2 Electron injection layer, Alq ...

Embodiment 2

[0050] ITO: indium tin oxide;

[0051] ZnO: zinc oxide;

[0052] MgF2: magnesium fluoride

[0053] NPB: (N,N'-diphenyl-N,N'-(1-naphthyl)-1,1'-biphenyl-4,4'-diamine);

[0054] C545T: 2,3,6,7-tetrahydro-1,1,7,7-tetramethyl-1H,5H,11H-10-(2-benzothiazolyl)-quinazino[9,9A, 1GH] coumarin;

[0055] MADN: 2-methyl-9,10-bis(naphthalen-2-yl)anthracene

[0056] Alq 3 : aluminum octahydroxyquinoline;

[0057] Al: aluminum.

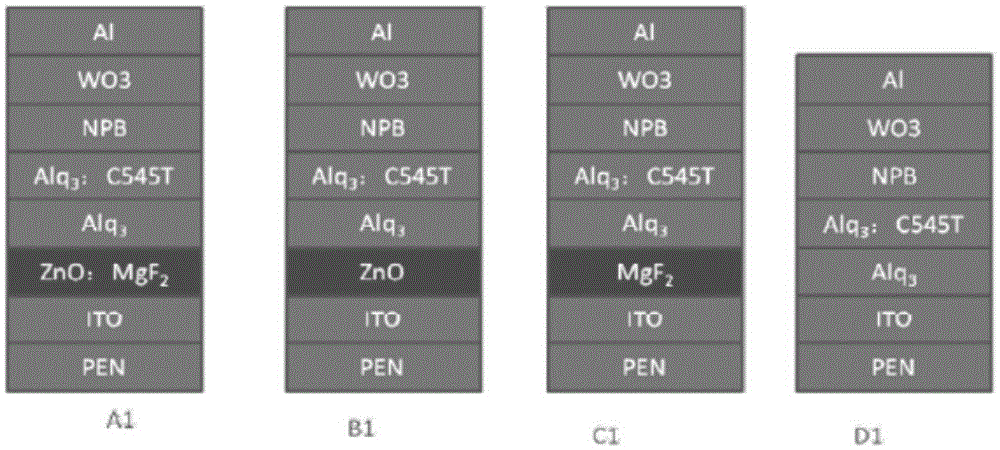

[0058] The structure of the prepared device A2 is: PEN (substrate) / ITO (cathode layer) / ZnO:MgF 2 (electron injection layer) / Alq 3 (electron transport layer) / Alq 3 : C545T (green fluorescent light-emitting layer) / NPB (hole transport layer) / WO3( hole injection layer) / Al (anode layer).

[0059] The optical refractive index of the electron injection layer is 1.82.

[0060] The preparation method is as follows:

[0061] After selecting the PEN substrate, prepare the ITO cathode layer, ZnO:MgF 2 Electron injection layer, Alq 3 electron transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com