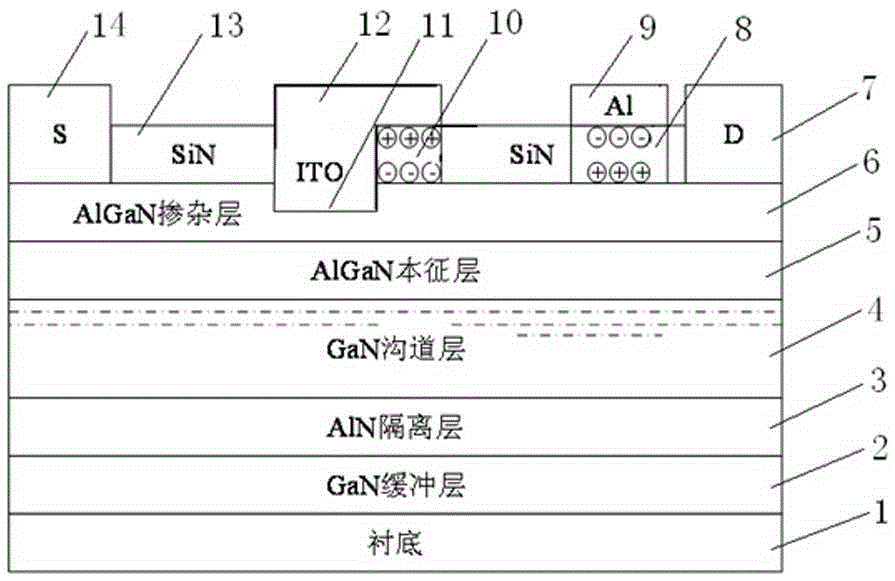

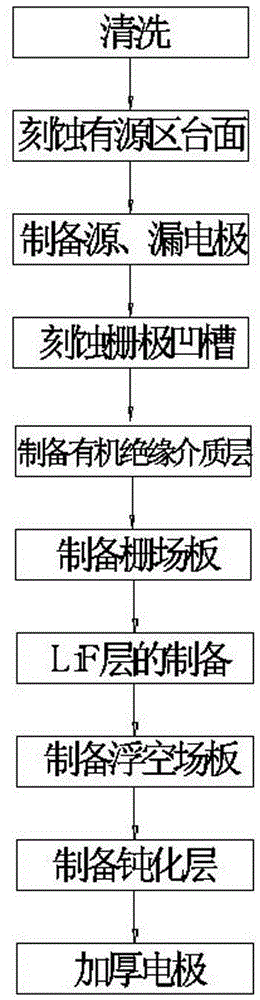

Trench-gate AlGaN/GaN HEMT device structure and manufacturing method

A technology of devices and trench gates, which is applied to the structure and manufacture of AlGaN/GaN HEMT devices with floating gate composite field plate trench gates, and in the field of AlGaN/GaN high electron mobility transistors, which can solve the problems of withstand voltage, on-resistance and frequency characteristics. Practical application and other issues, to achieve the effect of reducing the peak value of the electric field, reducing the on-resistance, and increasing the control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] refer to figure 1 , a floating-gate compound field plate trench gate AlGaN / GaN HEMT device structure of the present invention, comprising a substrate 1, a GaN buffer layer 2, an AlN isolation layer 3, a GaN channel layer 4, an intrinsic AlGaN layer 5, and an AlGaN doped layer 6. PTFE organic insulating medium layer 10 and LiF layer 8, ITO gate field plate 12, Al floating field plate 9, passivation layer 13, gate, drain electrode 7 and source electrode 14. The device structure from bottom to top is: substrate 1, GaN buffer layer 2, AlN isolation layer 3, GaN channel layer 4, intrinsic AlGaN layer 5, AlGaN doped layer 6, on which AlGaN doped layer 6 is set The active electrode 14, the drain electrode 7, the organic insulating medium layer 10, the LiF layer 8, the ITO gate field plate 12 and the passivation layer 13, the source electrode 14 and the drain electrode 7 are arranged at both ends above the AlGaN doped layer 6, The LiF layer 8 is close to the drain electrode 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com