Exhaust purifier for backflushing and removing black smoke blocker particles through exhaust

A technology of exhaust purifier and interceptor, which is applied in the direction of exhaust treatment, exhaust device, machine/engine, etc., can solve the problems of short service life, frequent replacement, low interception rate, etc., and achieve long service life cycle and high contribution rate High, environmental protection and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

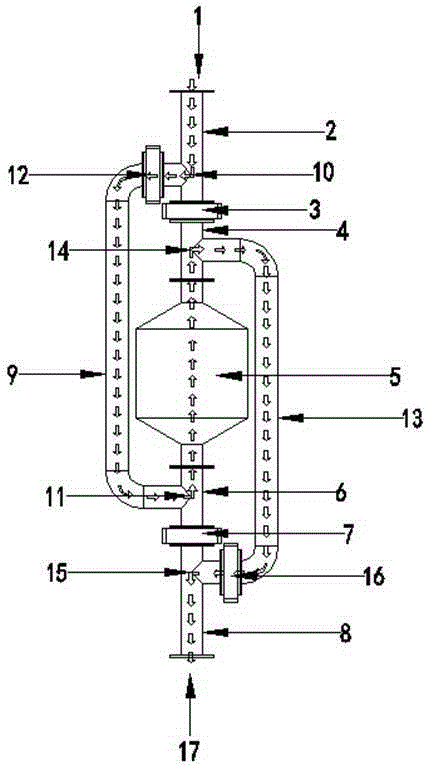

[0018] The working principle of the present invention is: when the automobile tail gas enters the tail gas purifier from the air inlet, the redox reaction will occur when the tail gas passes through the catalytic oxidant in the pipeline, and the harmful components CO, HC, CH4, NOx, etc. in the tail gas will be converted into CO2, N2 and H2O, leaving only particulate matter. Then pass through the muffler in the black smoke interceptor and the black smoke interceptor to intercept particles. After a long time, the intercepted particles will accumulate a lot on the black smoke interceptor, causing the blockage to be blocked. Therefore, the present invention utilizes recoil function combined with structural design, and forms different exhaust routes by adjusting the opening and closing of valves, so as to realize recoil and remove particulate matter. The recoil of the present invention is mutual, and recoil cleaning can be realized for interceptors (DPF) at different positions by ...

Embodiment 2

[0023] Such as Figure 4 As shown, in this embodiment, the air inlet 1 is sequentially connected to the upper section of the intake pipe 2, the intake valve 3, the lower section of the intake pipe 4, the black smoke interceptor 5, the upper section of the exhaust pipe 6, the exhaust valve 7, the exhaust Pipe lower section 8, exhaust port 17, the recoil intake pipe 9 is connected to the exhaust end of the intake pipe upper section 2 and the black smoke interceptor 5, the recoil intake pipe intake end 10 is connected to the intake pipe upper section 2, and the recoil intake pipe The exhaust end 11 is connected to the exhaust end of the black smoke interceptor 5, the recoil intake pipe 9 is provided with a recoil intake valve 12, and the other end of the black smoke interceptor 5 opposite to the exhaust pipe is connected with a recoil row. The gas pipe 13 and the recoil exhaust pipe 13 are provided with a recoil exhaust valve 16 . Catalytic oxidizers 18 are respectively arranged...

Embodiment 3

[0027] Such as Figure 7 As shown, the air inlet 1 on the air intake pipe of the present invention is successively connected with the upper section 2 of the air intake pipe, the intake valve 3, the lower section 4 of the air intake pipe, the black smoke interceptor 5, the upper section 6 of the exhaust pipe, and the right black smoke interceptor 5 -5, exhaust valve 7, exhaust pipe lower section 8, exhaust port 17, between the intake pipe upper section 2 and exhaust pipe upper section 6, recoil intake pipe 9 and right black smoke interceptor 5-5 are connected successively, Also be connected with recoil intake valve 12 on recoil intake pipe 9, also be connected with recoil exhaust pipe 13 on intake pipe lower section 4, be connected with recoil exhaust valve 16 on recoil exhaust pipe 13. The upper section 2 of the intake pipe, the lower section 4 of the intake pipe and the recoil intake pipe 9 are respectively provided with a catalytic oxidant 18, and the black smoke interceptor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com