Circuit board for replacing golden metal strips and manufacturing method of circuit board

A manufacturing method and circuit board technology, which are applied in the directions of printed circuit components, electrical connection printed components, etc., can solve the problems of low reliability and high manufacturing cost of gold fingers, and achieve high application reliability, low manufacturing cost, and improved wear resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

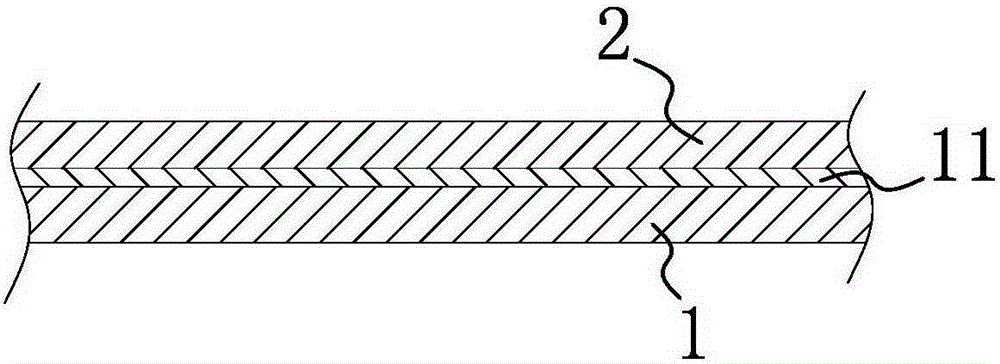

[0031] Such as figure 1 As shown, the circuit board manufacturing method used to replace gold fingers includes the following steps: A, pretreating the semi-finished circuit board 1 after solder masking; B, performing alloy electroplating on the semi-finished circuit board 1 after completing the pretreatment so that at least one layer of alloy layer 2 is formed on the surface of the copper layer 11 of the plug-in connection position of the semi-finished circuit board 1, and the alloy layer 2 is composed of chemical elements copper and chemical elements zinc, tin, nickel, cobalt, chromium, silver, gold , iron, lead, platinum, rhodium, palladium, indium at least one composition, then the semi-finished circuit board 1 after alloy electroplating is washed; The finished circuit board is made, preferably, the alloy layer 2 here can be any one of the chemical element copper and the chemical element zinc, tin, nickel, cobalt, chromium, silver, gold, iron, lead, platinum, rhodium, palla...

Embodiment 2

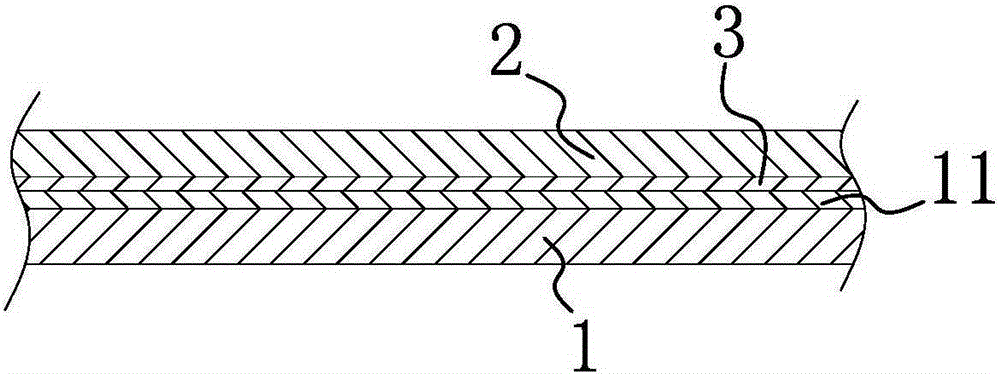

[0037] Such as figure 2 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference is that, when the alloy layer 2 is electroplated, an intermediate layer 3 can be provided between the copper layer 11 and the alloy layer 2, And the intermediate layer 3 is composed of any one or more of the chemical elements nickel, tin and zinc, that is, the electroplating of the alloy layer 2 can be directly plated on the copper layer 11, or other elements can be plated on the surface of the copper layer 11. Metals, such as nickel, tin, zinc, etc., are then plated with the alloy layer 2 on the surfaces of these metals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com