New method for preparing indium nitride nano material

A technology of nano-indium nitride and a new method, which is applied in the direction of chemical instruments and methods, nanotechnology, nitrogen compounds, etc., can solve the problems of high reaction temperature, sensitivity, harsh synthesis conditions, etc., and achieve simple and easy control of the reaction process and the source of raw materials Broad, low reaction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 1 gram of indium trioxide, 1 gram of sublimed sulfur and 4 grams of sodium amide into a 20 ml stainless steel autoclave, seal it and put it into an electric furnace capable of temperature programming, and the furnace temperature rises from room temperature to 190°C, then maintained at 190°C for 30 hours and then naturally cooled to room temperature. The final product in the autoclave consisted of black deposits and residual gas. Collect the black sediment stuck on the inner surface of the kettle wall, wash it with distilled water and absolute ethanol several times, filter the sample obtained, and dry the sample in a vacuum drying oven at 50°C for 4 hours, and finally collect it for characterization .

[0033] The phase analysis of the powder was carried out by using the Japanese RigakuD / max-γA X-ray powder diffraction (XRD) instrument, CuKα Graphite monochromator, tube voltage and current are 40kV and 20mA, scanning speed 10.0° min -1 .

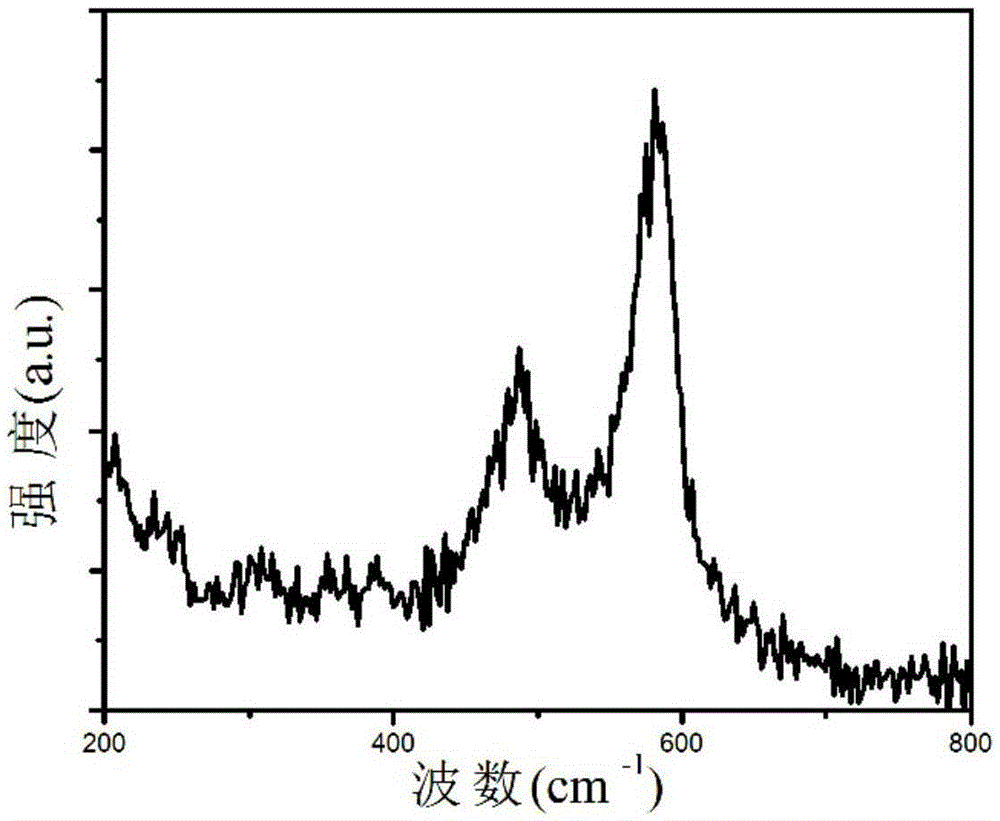

[0034] figure 1 It is...

Embodiment 2

[0040] The difference from Example 1 is that the reaction temperature is 350°C, and the reaction time is 10 hours. 1 gram of indium trioxide, 1 gram of sublimed sulfur and 4 grams of sodium amide are added to a 20 ml stainless steel high-pressure After sealing it, put it into an electric furnace capable of temperature-programming, then maintain it at 350°C for 10 hours, and then cool it down to room temperature naturally. The final product in the autoclave consisted of black deposits and residual gas. The black sediment stuck to the inner surface of the kettle wall was collected and washed several times, and the samples obtained after centrifugation were dried in a vacuum oven at 50°C for 4 hours, and finally collected for characterization.

[0041] To the X-ray diffraction figure ( Figure 5 ), obtain the same result as in Example 1.

Embodiment 3

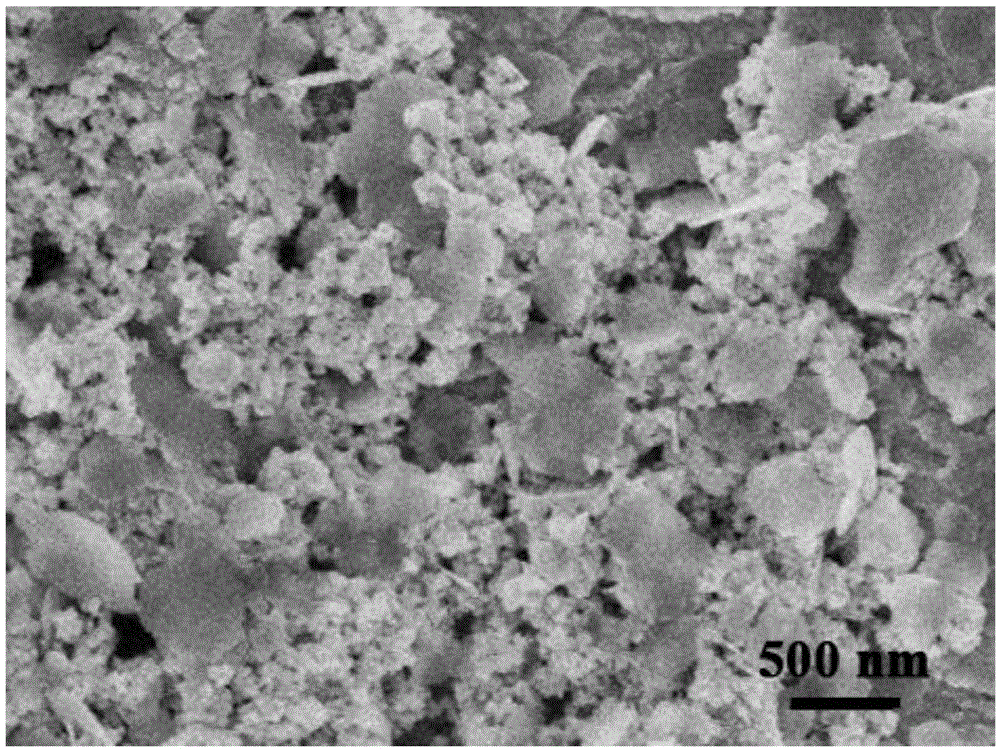

[0043] The difference from Example 1 is that indium chloride is used as the indium-containing compound, the raw material diindium trioxide used in Example 1 can be replaced by indium chloride, and other conditions remain unchanged. Take 0.7 g of indium chloride, put it into a 20 mL stainless steel autoclave with 0.5 g of sublimed sulfur and 4.0 g of sodium amide, seal it and place it in a resistance furnace, react at 190 °C for 30 hours, and then naturally cool to room temperature. Open the autoclave, wash the obtained product, centrifuge to obtain a solid, and perform an X-ray diffraction pattern on the obtained indium nitride material ( Figure 6 ), SEM ( Figure 7 ), it can be seen from the scanning electron microscope of the product that the indium nitride is a particle of 50-200 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com