Deep-hole machining online deviation rectifying device based on laser detection principle

A technology of laser detection and correction device, which is applied in the direction of feeding device, metal processing, automatic control device, etc. It can solve the problems such as difficult to observe the processing part and the condition of the tool, and achieve the effect of avoiding adverse effects, small size and promoting solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

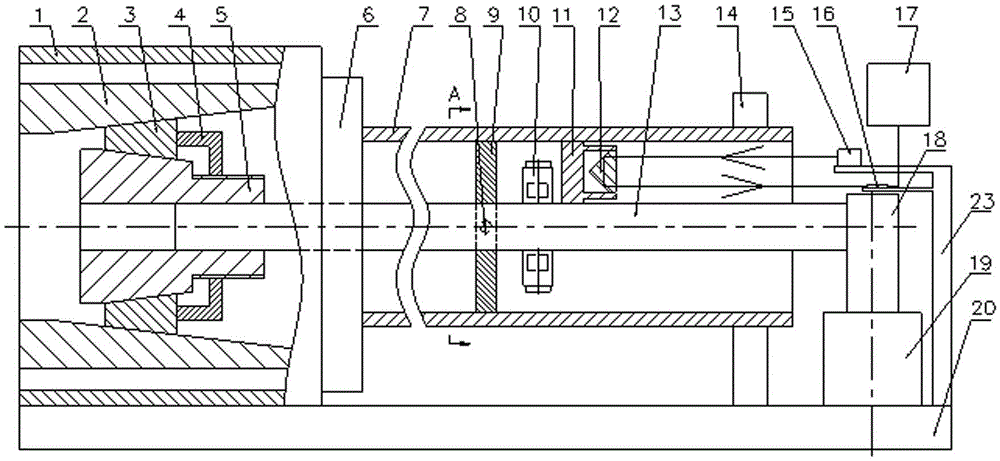

[0019] Such as figure 1 , figure 2 , image 3 As shown, the workpiece 7 of the present invention rotates, and the deep hole cutter 9 feeds. Bottom hole is arranged on workpiece 7, needs the deep hole of boring axis level.

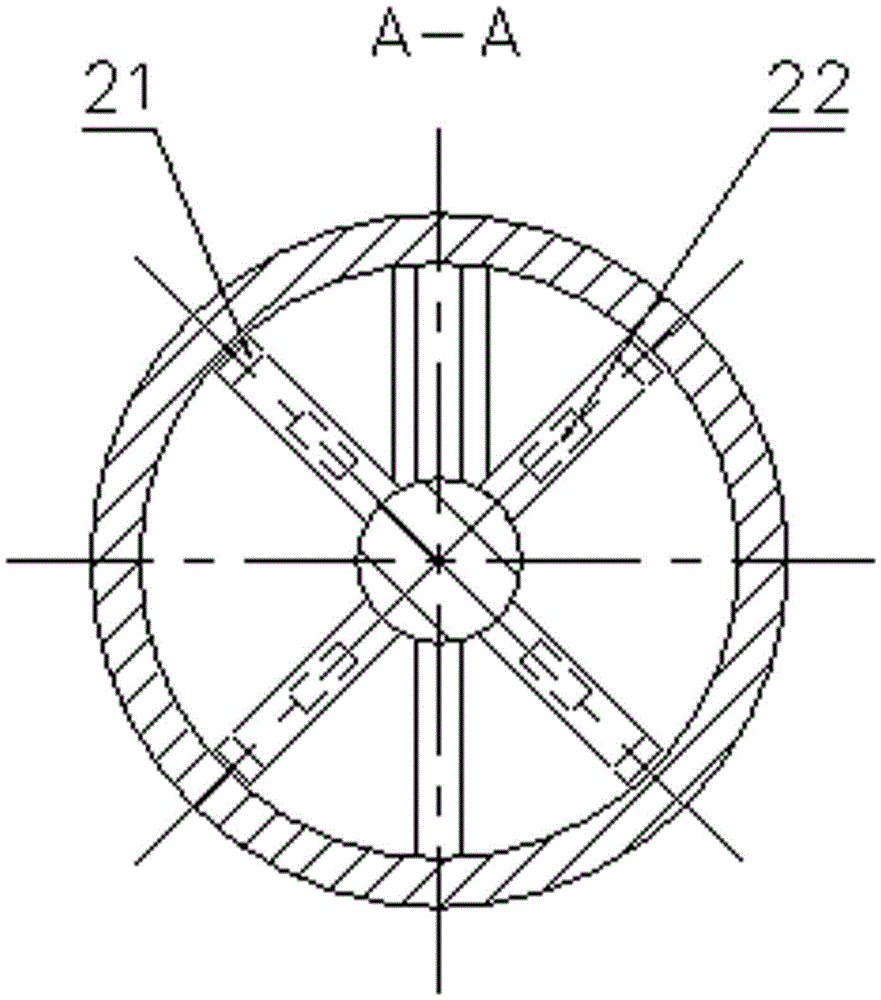

[0020] The present invention comprises deep hole tool 9, cutter bar 13, main shaft box 1, main shaft 2, expansion sleeve 3, fastening nut 4, core sleeve 5, holder 6, fastening screw 8, metal block 10, corner pyramid prism support Seat 11, corner cube prism 12, center frame 14, laser emitting device 15, photosensitive sensor 16, computer 17, cutter bar support 18, sliding plate 19, machine bed 20, wear-resistant and heat-resistant block 21, heating device 22, outer rack 23, laser orientation block 24, etc. Through the rotation of the workpiece 7, the deep hole tool 9 is fed to process the deep hole; one end of the workpiece 7 is clamped and positioned by the clamper 6, and the other end is supported by the center frame 14, which is driven to rotate by t...

Embodiment approach 2

[0023] In the second embodiment, there is no bottom hole on the workpiece 7, and a deep hole with a horizontal axis needs to be processed. In this case, the non-expansion sleeve 3, fastening nut 4, and core sleeve 5 of the present invention are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com