Device for assessing extent of degradation in secondary cell

A secondary battery and judging device technology, applied to battery circuit devices, circuit devices, battery/fuel cell control devices, etc., can solve problems such as inability to directly measure OCV and difficulty in estimating OCV

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

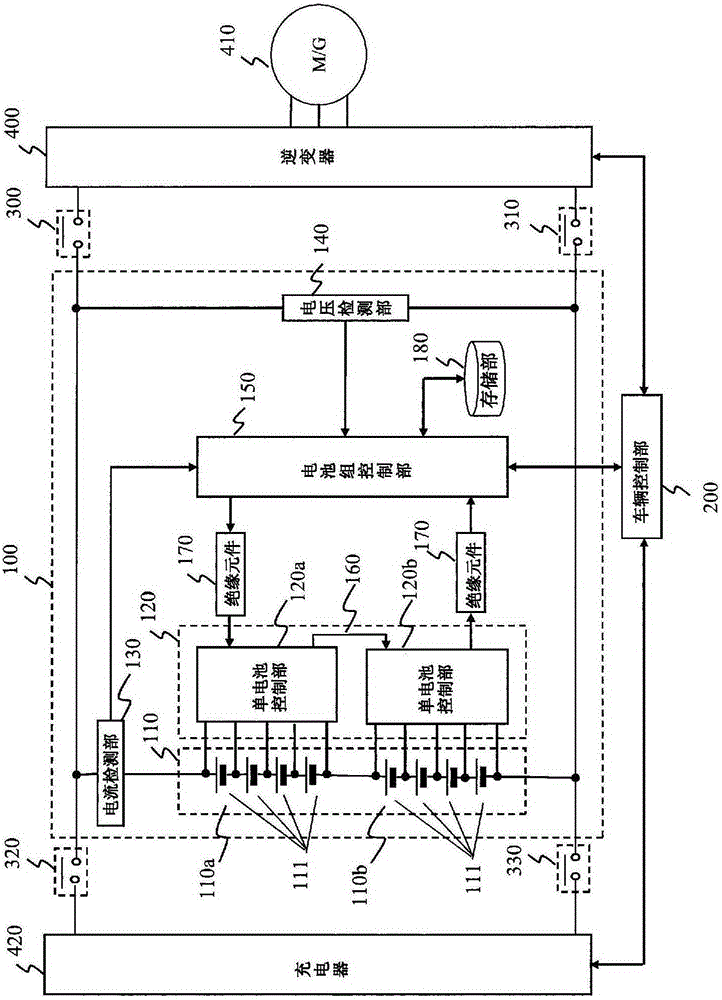

[0030] figure 1 It is a block diagram showing the circuit configuration of the battery system 100 and its periphery according to the embodiment of the present invention. Battery system 100 is connected to vehicle control unit 200 , and vehicle control unit 200 controls relays 300 and 310 to connect battery system 100 to inverter 400 . Furthermore, vehicle control unit 200 controls relays 320 and 330 to connect battery system 100 to charger 420 .

[0031] The battery system 100 includes a battery pack 110 , a cell control unit 120 , a current detection unit 130 , a voltage detection unit 140 , a battery pack control unit 150 , and a storage unit 180 .

[0032] The battery pack 110 is a secondary battery and is composed of unit cell groups 110 a and 110 b , and the unit cell groups 110 a and 110 b are each composed of a plurality of unit cells 111 .

[0033] The battery pack 110 is configured by electrically connecting a plurality of cells 111 capable of storing and dischargin...

no. 2 approach

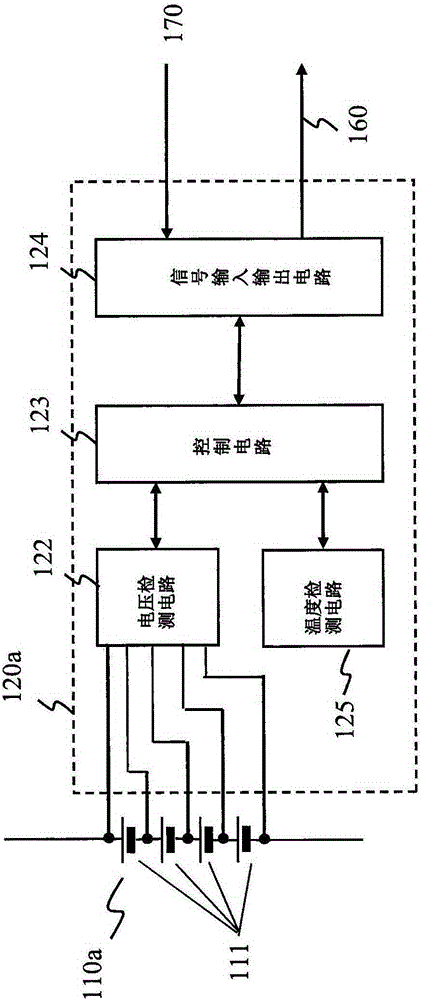

[0069] Next, a second embodiment of the present invention will be described. The block diagram and the circuit structure of the battery system 100 and its surroundings in the second embodiment figure 1 Similarly, the block diagram showing the circuit configuration of the cell control unit 120a is the same as figure 2 Since they are the same, the description of each block diagram is omitted.

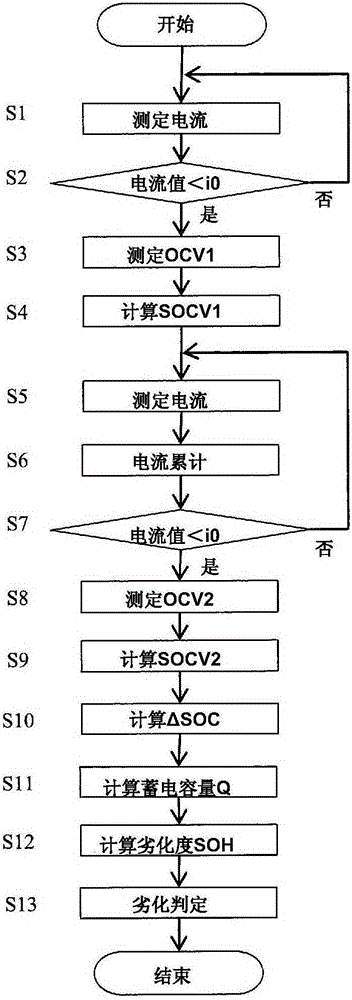

[0070] refer to Figure 4 The operation of determining the degree of deterioration of the secondary battery according to the second embodiment of the present invention will be described.

[0071] Figure 4 This is a flow chart for determining the degree of deterioration of the secondary battery. The processing operations shown in this flowchart are repeatedly executed by the battery pack control unit 150 at regular intervals or at regular intervals while the vehicle is running. image 3 The steps of the same processing operations as the steps shown in are denoted by the same symbols...

no. 3 approach

[0078] Next, a third embodiment of the present invention will be described. The block diagram and the circuit structure of the battery system 100 and its surroundings in the third embodiment figure 1 Similarly, the block diagram showing the circuit configuration of the cell control unit 120a is the same as figure 2 Since they are the same, the description of each block diagram is omitted.

[0079] refer to Figure 5 The operation of determining the degree of deterioration of the secondary battery according to the third embodiment of the present invention will be described.

[0080] Figure 5 This is a flow chart for determining the degree of deterioration of the secondary battery. The processing operations shown in this flowchart are repeatedly executed by the battery pack control unit 150 at regular intervals or at regular intervals while the vehicle is running. image 3 The steps of the same processing operations as the steps shown in are denoted by the same symbols an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com