Nitrogen-enriched carbon based/sulfur composite cathode material used for lithium sulphur batteries, and preparation method thereof

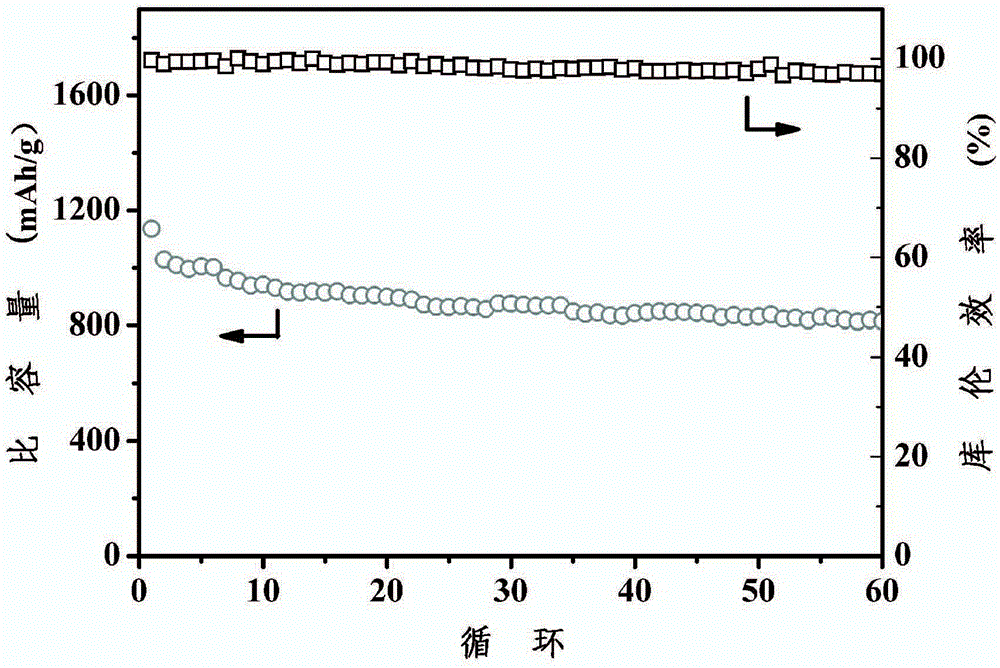

A composite cathode material, lithium-sulfur battery technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of restricting the marketization of lithium-sulfur batteries, low coulombic efficiency of lithium-sulfur batteries, and poor conductivity of sulfur. Achieve the effect of improving coulombic efficiency and cycle performance, improving high-rate charge-discharging performance, and inhibiting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step: prepare 10L of sodium carbonate aqueous solution with a mass fraction of 1%, add 100g of silkworm cocoons, cook for 30 minutes, and dry at 60°C after repeated washing to obtain silk fibroin; prepare 100ml of potassium bromide aqueous solution with a mass fraction of 60%, add 15g After the silk fibroin was shaken for 2 hours to dissolve the silk fibroin, a dialysis bag with a molecular weight of 14,000 was used for 64 hours of dialysis to obtain an aqueous silk fibroin solution.

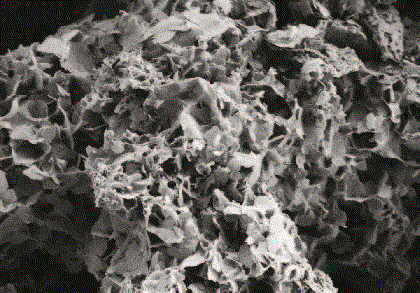

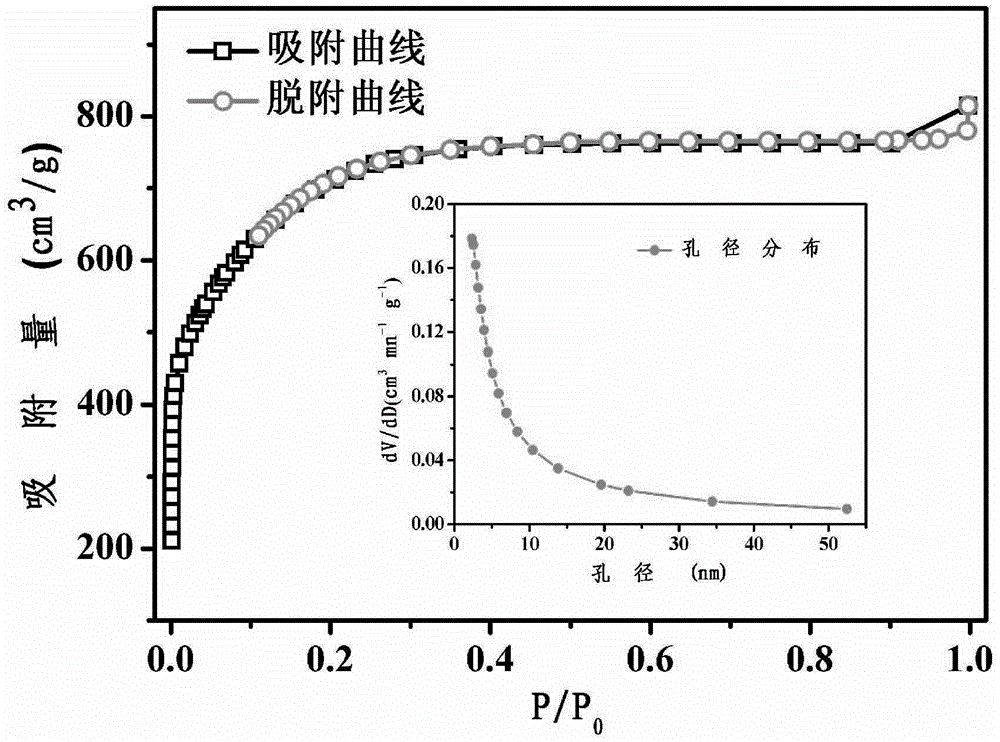

[0025] Step 2: Take 100ml of the above silk fibroin solution, add potassium hydroxide to make the mass concentration of potassium hydroxide 2.5%, stir for 120 minutes, freeze-dry, transfer the above mixture to a tube furnace, and keep it warm at 800°C for 3 hours under an argon atmosphere. Hours (heating rate 5°C / min), the product is washed with water until neutral and then dried (the absolute vacuum degree of vacuum drying is 100Pa, the drying temperature is 100°C, and the dryin...

Embodiment 2

[0029]Step 1: prepare 10L of sodium carbonate aqueous solution with a mass fraction of 1%, add 100g of silkworm cocoons, cook for 30 minutes, dry at 60°C to obtain silk fibroin after repeated washing; prepare 100ml of a 20% zinc chloride aqueous solution, add 15g After the silk fibroin was shaken for 2 hours to dissolve the silk fibroin, a dialysis bag with a molecular weight of 3000 was used for 36 hours to obtain an aqueous silk fibroin solution.

[0030] Step 2: Take 100ml of the above silk fibroin solution, add potassium hydroxide to make the mass concentration of potassium hydroxide 0.1%, stir for 30 minutes, freeze-dry, transfer the above mixture to a tube furnace, and keep it warm at 600°C for 5 minutes under an argon atmosphere. Hours (heating rate 5°C / min), the product is washed with water until neutral and then dried (the absolute vacuum degree of vacuum drying is 100Pa, the drying temperature is 100°C, and the drying time is 12 hours. The silk prepared by this method...

Embodiment 3

[0034] The first step: prepare 10L of sodium carbonate aqueous solution with a mass fraction of 1%, add 100g of silkworm cocoons, cook for 30 minutes, and dry at 60°C after repeated washing to obtain silk fibroin; prepare 100ml of potassium bromide aqueous solution with a mass fraction of 60%, add 10g After the silk fibroin was shaken for 2 hours to dissolve the silk fibroin, a dialysis bag with a molecular weight of 12,000 was used for dialysis for 24 hours to obtain an aqueous silk fibroin solution.

[0035] Step 2: Take 100ml of the above silk fibroin solution, add sodium hydroxide to make the mass concentration of sodium hydroxide 10%, stir for 60 minutes, freeze-dry, transfer the above mixture to a tube furnace, and keep it warm at 1200°C for 1 hour under a nitrogen atmosphere (heating rate 5°C / min), the product can be washed with water until neutral and then dried (the absolute vacuum degree of vacuum drying is 100Pa, the drying temperature is 60°C, and the drying time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com